Při těžbě ropy, geologickém průzkumu a podobných operacích slouží vrtací bláto jako „krev vrtání“, přičemž plní klíčové funkce, jako je odvádění vrtaného štěrku, chlazení vrtáku a vyrovnávání tlaku v ložisku. Během vrtání vznikají třením mezi vrtákem a horninou vysoké teploty a geotermální teplo z hlubokých vrstev neustále zvyšuje teplotu bláta.

Pokud se teplota bláta stane příliš vysokou, může to snížit mazací účinky a schopnost odvádět štěrk, urychlit opotřebení vrtáku a potenciálně degradovat výkon bláta nebo způsobit poruchy zařízení, čímž vážně ovlivní efektivitu vrtání a bezpečnost provozu. V tomto kontextu systém chlazení bláta funguje jako „strážce teploty“ a zajišťuje stabilní a efektivní vrtací operace.

Vysoce kvalitní chladicí systém bahna musí přesně regulovat teplotu bahna podle podmínek vrtání a udržovat ji v optimálním provozním rozsahu. Mnohé společnosti však v praxi čelí výzvám, jako je nedostatečná chladicí účinnost, vysoká spotřeba energie a obtíže s údržbou. Některé chladicí systémy mají špatnou přizpůsobivost a nedokáží splnit požadavky složitých vrtacích scénářů, zatímco jiné postrádají inteligentní monitorování, což ztěžuje včasné zjištění a reakci na poruchy, což může způsobit zpoždění provozu.

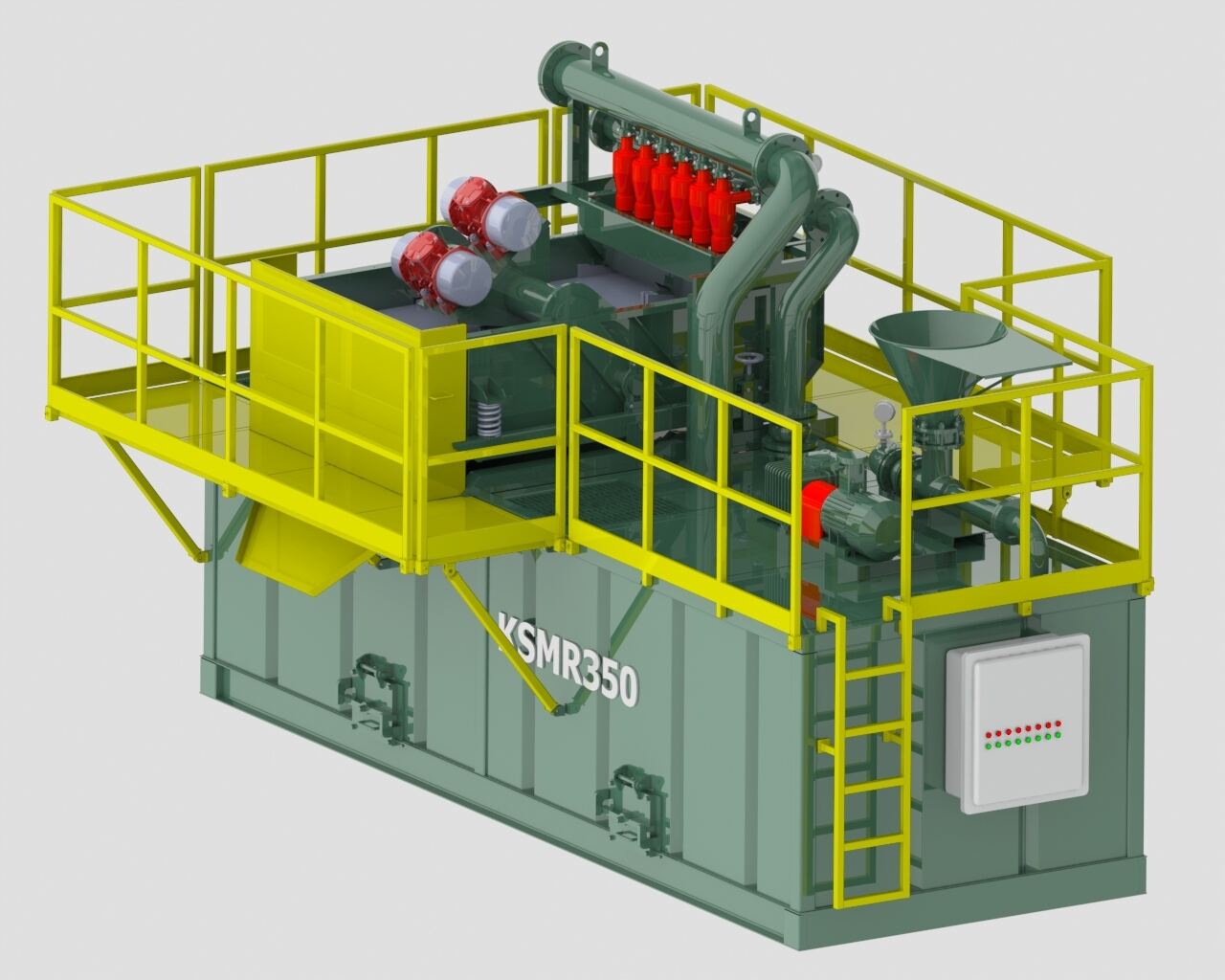

Pro splnění těchto klíčových požadavků průmyslu společnost Rhino Industrial Co., Ltd., která využívá své odborné znalosti v oblasti environmentálního a průmyslového zařízení, nabízí přizpůsobená řešení chladicích systémů bahna, která zajišťují stabilní a spolehlivou regulaci teploty pro vrtací operace.

Klíčové vlastnosti chladicího systému bahna od Rhino Industrial:

Komponenty výměníku tepla s vysokou účinností: Navrženy tak, aby odpovídaly průtoku bahna, teplotním požadavkům a podmínkám na místě, optimalizují přenos tepla pro rychlé ochlazení horkého bahna a zároveň snižují spotřebu energie a provozní náklady.

Inteligentní monitorovací modul: Neustále sbírá data o teplotě bahna, průtoku a provozu zařízení, která zobrazuje prostřednictvím vizuálního rozhraní pro operátory. Automatická upozornění pomáhají včasnému zjištění potenciálních problémů a snižují riziko poruch.

Návrh přizpůsobený konkrétním podmínkám lokality: Zajišťuje optimální uspořádání a stabilní provoz dle požadavků vrtné lokality.

Komplexní servisní podpora:

Servis po celý životní cyklus: Od výběru systému, instalace, uvádění do provozu až po údržbu, zajišťuje bezproblémový chod.

Pravidelné prohlídky: Pravidelné kontroly komponent výměníku tepla, potrubí a řídicích systémů, včasná výměna náchylných částí pro prodloužení životnosti zařízení.

Rychlá reakce: V případě neočekávaných problémů může podpůrný tým rychle dorazit na místo, odstranit závadu a provést opravu, čímž se minimalizuje výpadek provozu.

Kromě toho Rhino Industrial neustále aktualizuje systémy na základě pokroků v průmyslu a měnících se potřeb klientů, integruje účinnější energeticky úsporné komponenty a vylepšuje inteligentní řídicí algoritmy za účelem zvýšení výkonu a přizpůsobivosti systému.

Zvolením chladicího systému pro bahno od společnosti Rhino Industrial mohou firmy zajistit stabilní a efektivní vrtací operace, snížit celkové náklady díky přesné kontrole teploty a inteligentnímu provozu a zlepšit bezpečnost provozu. Do budoucna bude Rhino Industrial nadále zaměřovat svou pozornost na problémy v odvětví, podporovat inovace v chladicích systémech pro bahno a zajišťovat kvalitní vrtací operace napříč celým sektorem.