Նորամուծություններ, որոնք վերափոխում են ժամանակակից Դրիլինգի աղումների հաստատում

Նավթի և գազի արդյունաբերությունը վերջին տարիներին արձանագրել է հորատման աղբի վերահսկման տեխնոլոգիաների բնագավառում արձանագրված արդյունաբերական առաջընթացներ: Այս նորամուծությունները վերաձևակերպում են ընկերությունների կողմից հորատման աղբի վարման, մշակման և ոչնչացման ձևերը փորման աղբ մինչդեռ պահպանվում է շրջակա միջավայրի հետ համապատասխանությունը և գործողությունների արդյունավետությունը: Քանի դեռ շրջակա միջավայրի վերաբերյալ կանոնակարգերը ավելի խիստ են դառնում, իսկ կայունության նպատակները՝ ավելի համարձակ, արդյունավետ հորատման աղբի վերահսկման կարևորությունը չի կարող չափազանցվել:

Ժամանակակից փորման գործողությունները առաջացնում են աղբի մեծ քանակություն, ներառյալ փորման մանրաթելեր, վատնված փորման հեղուկներ և կեղտական նյութեր: Խնդիրը կայանում է ոչ միայն այդ թափոնների կառավարման, այլ նաև այնպես կառավարելու մեջ, որ նվազագույնի հասցնի ազդեցությունը շրջակա միջավայրի վրա՝ առավելագույն արդյունավետությամբ: Սա բերեց նորատիպ տեխնոլոգիաների և մեթոդների ստեղծմանը, որոնք փոխակերպում են փորման թափոնների վերահսկման ոլորտը:

Բարձրակարգ ջերմային մշակման համակարգեր

Կրկնակի մշակման միավորներ

Ջերմային դեսորբցիայի տեխնոլոգիան փորման թափոնների վերահսկման մեջ կատարելագործված մոտեցում է: Այս համակարգերը օգտագործում են ճշգրիտ վերահսկվող ջերմություն՝ հիդրոկարբուրները փորման մանրաթելերից և այլ պինդ թափոններից անջատելու համար: Գործընթացը սովորաբար իրականանում է 250°C-ից մինչև 350°C ջերմաստիճաններում, արդյունավետորեն հեռացնելով կեղտավորողներին՝ պահպանելով մշակված նյութերի ֆիզիկական հատկությունները:

Ժամանակակից ջերմային դեսորբցիայի միավորները բնութագրվում են բարելավված էներգաարդյունավետությամբ և ինքնաշխատ կառավարման համակարգերով, որոնք օպտիմալացնում են մշակման գործընթացը: Վերականգնված հիդրոկարբոնները կարող են վերադարձվել հորատման հեղուկի համակարգի մեջ, իսկ մաքրված պինդ նյութերը հաճախ համապատասխանում են բարենպաստ վերօգտագործման կամ անվտանգ հեռացման համար սահմանված էկոլոգիական չափանիշներին:

Միկրոալիքային մշակման տեխնոլոգիա

Միկրոալիքային մշակումը հորատման աղբի վերահսկման նորարական մոտեցում է, որն ունի մի շարք առավելություններ սովորական ջերմային մեթոդների համեմատ: Այս տեխնոլոգիան օգտագործում է էլեկտրամագնիսական ալիքներ՝ նպատակային ջերմաստիճանի նյութերի ըտրողական տաքացման համար, ուղղված ջրի և հիդրոկարբոնային մոլեկուլների վրա՝ էներգիայի սպառման նվազեցմամբ: Գործընթացը հատկապես արդյունավետ է յուղային կավի և աղտոտված հորատանցքերի մշակման համար:

Միկրոալիքային բուժման համակարգերի ճշգրտությունն ու արդյունավետությունը կտրուկ բարելավվել են. նոր սարքերը կարողանում են մշակել ավելի մեծ ծավալներ՝ պահպանելով համատեղելի որակի չափանիշներ: Տեխնոլոգիայի փոքրացված չափերն ու ցածր էներգետիկ պահանջները այն ավելի շատ են դարձնում հարկադրված հարթակների և ծովային կիրառությունների համար:

Քիմիական բուժման նորամուծումներ

Ընդլայնված օքսիդացման գործընթացներ

Քիմիական բուժման տեխնոլոգիաները զարգացել են ներառյալ բարդ օքսիդացման գործընթացներ, որոնք քայքայում են բարդ օրգանական միացությունները փորվածքների աղբում: Այս համակարգերը օգտագործում են օքսիդիչ նյութերի, կատալիզատորների և ՈՒՖ ճառագայթման համակցումներ՝ բուժման ավելի լավ արդյունքների հասնելու համար: Այս ոլորտի վերջին մշակումները կենտրոնանում են քիմիական նյութերի օգտագործման օպտիմալացման և բուժման արդյունավետության առավելագույն մեծացման վրա:

Ժամանակակից օքսիդացման համակարգերը ներառում են իրական ժամանակի հսկողություն և ավտոմատացված չափաբաժների վերահսկում՝ ապահովելու օպտիմալ մշակման պայմաններ: Այս ճշգրիտ մոտեցումը բարելավում է մշակման արդյունավետությունը և նվազեցնում է քիմիական նյութերի ծախսը և շահագործման ծախսերը:

Կայունացման և ամրացման տեխնոլոգիաներ

Նոր կայունացման և ամրացման տեխնոլոգիաները օգտագործում են առաջադեմ կապակցող նյութեր և բարդ խառնման համակարգեր՝ հեղուկ և կիսահեղուկ թափոնները վերածելով կայուն, արտահոսքից ազատ պինդ նյութերի: Այս համակարգերը կարող են մշակել տարբեր տեսակի փորման թափոններ, միևնույն ժամանակ ապահովելով, որ վերջնական արտադրանքը համապատասխանում է բացթողնման կամ օգտակար վերօգտագործման համար նախատեսված խիստ պահանջներին:

Վերջերս կապակցող նյութերի բաղադրության մեջ մտցված նորամուծությունները բարելավել են մշակման գործընթացի արդյունավետությունը՝ նվազեցնելով ավելացուցիչների անհրաժեշտ ծավալը: Այս առաջընթացը տեխնոլոգիան դարձրել է ավելի տնտեսապես արդյունավետ և էկոլոգիապես կայուն:

Մեխանիկական հանգումների տեխնոլոգիաներ

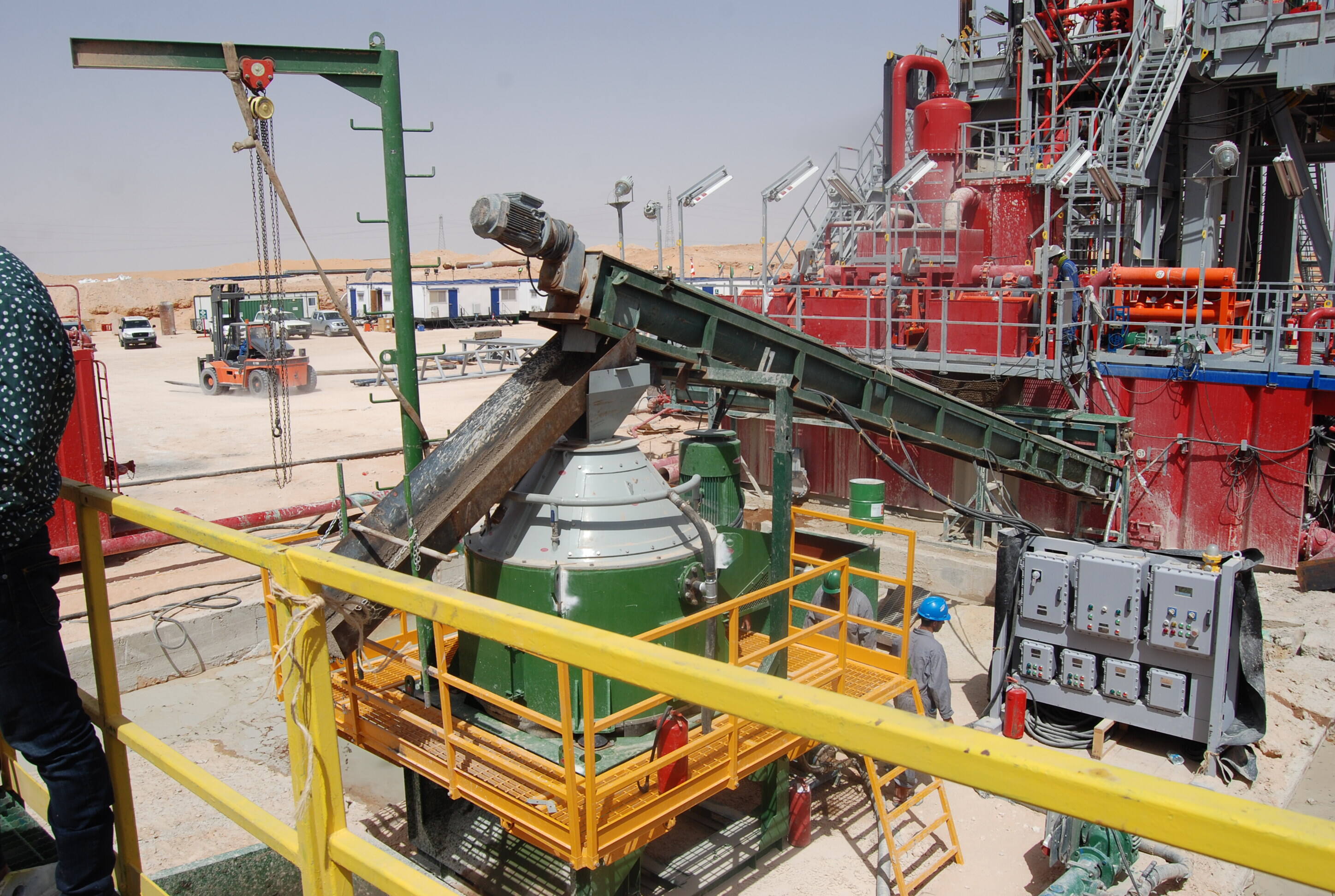

Բարձր կատարուղացման ցենտրիֆուգներ

Ցենտրոբեժ անջատման համակարգերի վերջին սերունդը ներկայացնում է հորատման թափոնների վերահսկման տեխնոլոգիայի մեջ կատարողական առաջընթաց: Այս սարքերը համալրված են բարելավված կոնաձև կառուցվածքներով, փոփոխական հաճախականության վերահսկողական համակարգերով և ինքնաշխատ կառավարման համակարգերով, որոնք ապահովում են անջատման արդյունավետության ավելացումը՝ նվազեցնելով էներգիայի սպառումը:

Ժամանակակից ցենտրոբեժերը կարողանում են ապահովել ավելի բարձր ցենտրոբեժ ուժեր և մշակել ավելի մեծ ծավալներ թափոններ, ինչի արդյունքում առաջանում են մաքրված ապրանքանիշեր և նվազում է թափոնների վերացման ծավալը: Ինտելեկտուալ վերահսկողական համակարգերի ներդրումը թույլ է տալիս իրական ժամանակում կատարել շահագործման պարամետրերի ճշգրտումներ տարբեր պայմաններում արդյունավետ աշխատանք պահպանելու համար:

Ավանդական ֆիլտրացիայի համակարգեր

Ֆիլտրման տեխնոլոգիան զարգացել է և ներառում է բարդ թաղանթային համակարգեր և հիբրիդ կառուցվածքներ, որոնք կարողանում են մշակել բարդ թափոնների հոսքերը: Այս համակարգերը համատեղում են բազում ֆիլտրման փուլեր՝ ինքնաշխատ հետընթաց լվացմամբ և ինքնամաքրման հնարավորություններով՝ ապահովելով կայուն աշխատանք մինիմալ սպասարկման պայմաններում:

Ամենանոր ֆիլտրման համակարգերը ներառում են խելացի հսկման համակարգեր, որոնք հետևում են ֆիլտրի աշխատանքին և կանխատեսում են սպասարկման կարիքները՝ օգնելով օպտիմալացնել գործողությունը և կրճատել դադարի ժամանակը: Առաջադեմ մեմբրանային նյութերը առաջարկում են բարելավված տևականություն և ավելի լավ անջատման արդյունավետություն, դարձնելով այս համակարգերը ավելի գործնական հորատման թափոնների վերահսկման կիրառումների համար:

Թվային ինտեգրում և ավտոմատացում

Կարիքավոր Նախադասումների Սիสเตմներ

Թվային տեխնոլոգիաները փոխակերպել են հորատման թափոնների վերահսկումը՝ ներառելով բարդ հսկողության և կառավարման համակարգեր: Այս համակարգերը օգտագործում են սենսորներ, տվյալների վերլուծություն և արհեստական ինտելեկտ ՝ իրական ժամանակում օպտիմալացնելու մշակման գործընթացները: Օպերատորները հիմա կարող են միաժամանակ հետևել մի քանի պարամետրերի և անմիջապես կատարել ճշգրտումներ՝ պահպանելու օպտիմալ աշխատանքի համար:

Վերջին հսկման համակարգերը ներառում են կանխատեսողական պահպանման հնարավորություններ և հեռահաղորդակցական հսկման հատկություններ, որոնք թույլ են տալիս օպերատորներին նույնականացնել և հասցնել հնարավոր խնդիրները, մինչև դրանք ազդեն գործողությունների վրա: Այս նախօրոք մտածված մոտեցումը օգնում է նվազագույնի հասցնել կանգառները և ապահովել մշտական մշակման որակը:

Ավտոմատացված պրոցեսի կառավարում

Ինքնաշխատ տեխնոլոգիան հեղափոխել է փոշու վերահսկման գործողությունները՝ ներմուծելով բարդ վերահսկման համակարգեր, որոնք ինքնաբերաբար օպտիմալացնում են մշակման գործընթացները: Այդ համակարգերը կարող են իրական ժամանակում կարգավորել գործառնական պարամետրերը՝ կախված աղբի հատկանիշներից և մշակման պահանջներից՝ ապահովելով համապատասխան արդյունքներ, մինչդեռ նվազեցնում են օպերատորի միջամտությունը:

Ժամանակակից ինքնաշխատ համակարգերը ներառում են մեքենայական ուսուցման ալգորիթմներ, որոնք անընդհատ բարելավում են գործընթացի արդյունավետությունը՝ կախված գործողական տվյալներից: Այս հնարավորությունը օգնում է նվազեցնել շահագործման ծախսերը՝ պահպանելով բարձր մշակման չափանիշները և էկոլոգիական համապատասխանությունը:

Հաճախ տրվող հարցեր

Ինչպե՞ս են ջերմային կլանման միավորները համեմատվում ավանդական աղբի մշակման մեթոդների հետ:

Ներկայացված մեթոդների համեմատ ջերմային դեսորբցիայի միավորները ավելի բարձր բուժման արդյունավետություն են ապահովում և ավելի լավ էկոլոգիական արդյունքներ: Դրանք կարող են մշակել ավելի մեծ ծավալով թափոններ, իսկ աղտոտողների հեռացման արագությունը բարձր է, իսկ մաքրված նյութերը կարող են օգտակար վերօգտագործվել:

Ի՞նչ են ավտոմատ հորատման թափոնների վերահսկման համակարգերի իրականացման հիմնական առավելությունները:

Ավտոմատ համակարգերը ավելի համապարփակ գործընթացների համապարփակություն, ցածր շահագործման ծախսեր և ավելի լավ էկոլոգիական համապատասխանություն են ապահովում: Նրանք նվազեցնում են մարդկային սխալները, օպտիմալ են դարձնում ռեսուրսների օգտագործումը և տրամադրում են մանրամասն կատարման տվյալներ կարգավորող հաշվետվությունների և համակարգի օպտիմիզացիայի համար:

Ինչպե՞ս են նոր ֆիլտրման տեխնոլոգիաները բարելավում հորատման թափոնների կառավարումը:

Առաջադեմ ֆիլտրման համակարգերը ավելի լավ անջատման արդյունավետություն են ապահովում, պահանջում են ավելի քիչ սպասարկում և կարող են մշակել ավելի մեծ թափոնների ծավալներ: Նրանք նաև ավելի մաքուր անջատված ապրանքներ են արտադրում և հաճախ ներառում են ինքնամաքրման հնարավորություններ, որոնք կրճատում են շահագործման դադարները: