ההשפעה הסביבתית של פסולת שמנונית לא מעובדת

הצטברות של שפכים שומניים בפעולות תעשייתיות מייצגת את אחד האתגרים הסביבתיים החשובים ביותר בעידן שלנו. פסולת מסוכנת זו, שנוצרת בעיקר במתקני רתיכות נפט, מתקני עיבוד שמן ותעשיות ייצור שונות, מהווה איום חמור על מערכות אקולוגיות ועל בריאות האדם כאשר היא נותרת לא מעובدة. המורכבות של טיפול בשמרים שמן נהיה חשוב יותר ויותר ככל שהתעשיות מתרחבות והתקנות הסביבתיות מחמירות ברחבי העולם.

תעשיית הנפט לבדה מייצרת מיליוני טונות של שלולית שמנונית מדי שנה, מה שמייצר צורך דחוף בפתרונות טיפול אפקטיביים. תערובת מסוכנת זו של שמן, מים וחלקיקים מוצקים מכילה חומרים רעילים רבים, כולל מתכות כבדות, הידרוקרבונים ארומטיים Policyclic (PAHs) וחומרים מזהמים מסוכנים אחרים שיכולים להתקיים בסביבה במשך עשורים אם לא יטופלו כראוי.

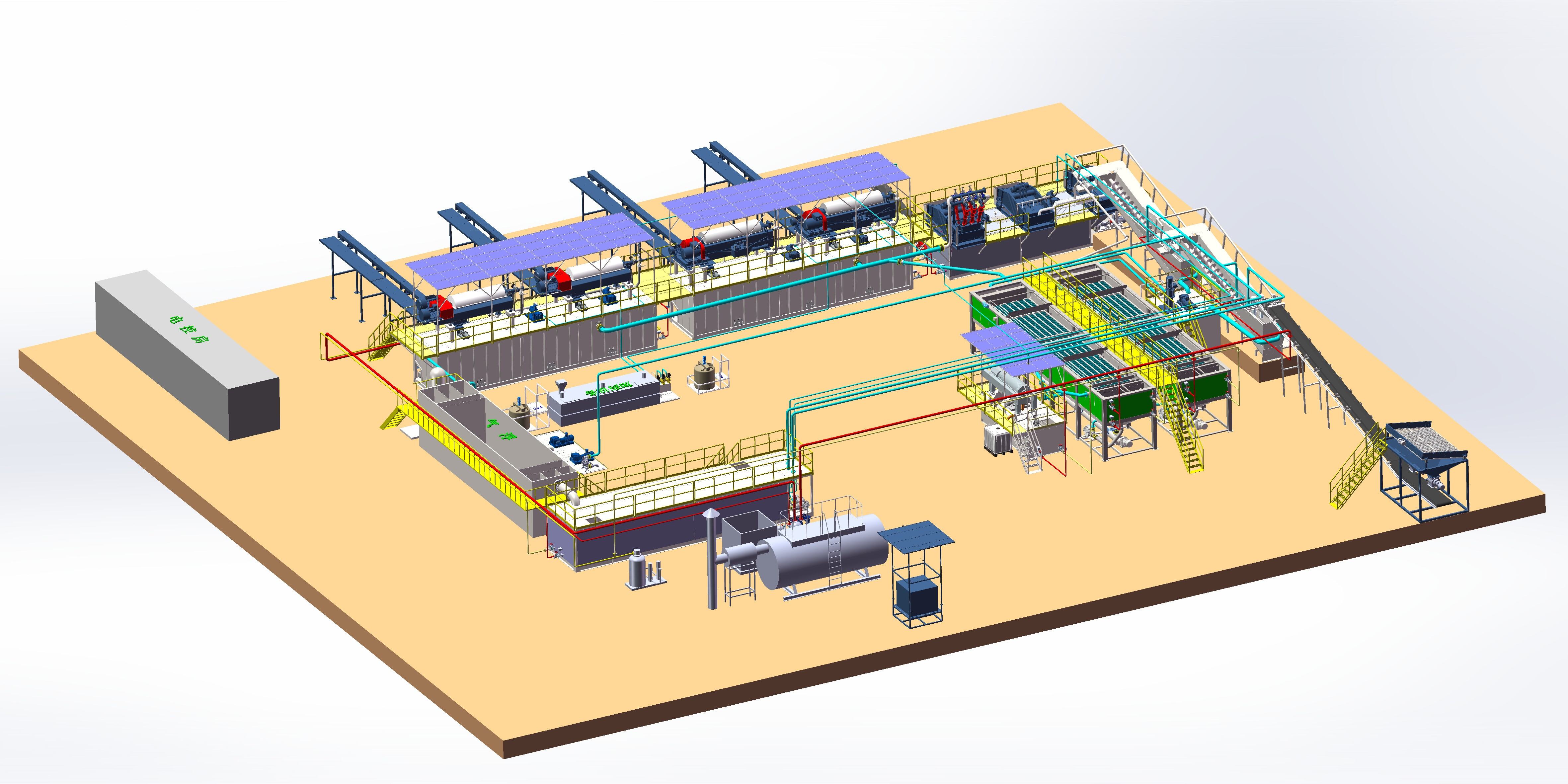

טכנולוגיות מתקדמות בתהליכי עיבוד שלולית מודרניים

שיטות טיפול כימי

טיפול מודרני בשלולית שמנונית כולל תהליכים כימיים מתוחכמים המפרקים שרשרות הידרוקרבון מורכבות למרכיבים בר-השגה. חומרי פירוק כימיים ממלאים תפקיד מרכזי בהפרדת מים משלבי השמן, בעוד שמשטחים עוזרים בהסרת שאריות הזיהום בצורה יעילה. טיפולים כימיים מתקדמים אלה מבטיחים שיעורי החזרה גבוהים יותר של הידרוקרבונים בעלי ערך, תוך מינימיזציה של ההשפעה על הסביבה.

חדשנות אחרונה בטכנולוגיות טיפול כימי gef'ota לפיתוח של חומרים ידידותיים לסביבה שמ log'ot תוצאות מרשימות מבלי להכניס חומרים מזיקים נוספים לסביבה. פתרונות מהפכניים אלו שינו את הדרך בה התעשיות מתמודדות עם טיפול בשפכים שומניים, וmakes אותם יותר בר-קיימא ויעיל מבחינה עלותית.

טכנולוגיות הפרדה פיזית

הפרדה פיזית מהווה עמוד תpora נוסף בטיפול יעיל בשפכים שומניים. טכניקות כמו צנטריפוגה, סינון והפרדה תרמית עברו התפתחות משמעותית, ומציעות יעילות משופרת בהפחתת שמן, מים ורכיבים מוצקים. שיטות אלו חשובות במיוחד מכיוון שהן יכולות לעבד כמויות גדולות של שפכים תוך שמירה על תקנים עקביים באיכות.

השילוב של מערכות אוטומטיות ומנגנוני בקרה מדויקים שיפר את אמינותם של תהליכי ההפרדה הפיזית. מתקנים מודרניים יכולים כיום להשיג קצבים של הפרדה שעד לפני כן נחשבו בלתי אפשריים, תוך שאיבת משאבים יקרים ושמירה על מינימום השפעה סביבתית.

הטבות סביבתיות של ניהול שפכים מתאים

הגנה על הקרקע ועל מקורות המים

יישום פרוטוקולים מקיפים לטיפול בשפכים שומניים ממלא תפקיד חשוב בהגנה על משאבי הקרקע והמים. ללא טיפול מתאים, רכיבים רעילים עלולים לחדור אל מערכות מימי שתה, להזין מקורות שתייה ולהזיק לאקוסיסטמות מים. תהליכי טיפול מקצועיים מבטיחים שהחומרים המסוכנים הללו יוחזקו ויועבדו בצורה בטוחה, ובכך מונעים נזק סביבתי ארוך טווח.

מניעת זיהום הקרקע באמצעות ניהול שפכים יעיל תורמת לשימור פוריון חקלאי וتنوع ביולוגי. טכניקות טיפול מודרניות יכולות לשחזר אדמות מזוהמות לשימוש פרודוקטיבי, ותומכות הן בשימור הסביבה והן ביציבות הכלכלית.

שיפור איכות האוויר

טיפול מתאים בשפכים שומניים מפחית בצורה ניכרת את הפלט של תרכובות hữuיות נדיפות (VOC) התורמות לזיהום האוויר. מתקני טיפול מתקדמים כוללים מערכות בקרת איכות אוויר שאוגרות ומעבדות גazy מזיקים, ומבטיחים אויר נקי יותר לקהילות הסמוכות. שיפורים באיכות האוויר יש להם השפעות חיוביות ישירות על בריאות הציבור ועל הרווחה הסביבתית.

יישום של מערכות טיפול במחזור סגור מהפכן את הדרך בה בתים תעשייתיים מנהלים את הפליטות לאויר במהלך עיבוד שפכים. פתרונות חדשניים אלו לא רק מגנים על האטמוספירה אלא גם משחזרים רכיבים בעלי ערך שניתן למחזר בחזרה לתהליכים תעשייתיים.

היתרונות הכלכליים של פתרונות טיפול יעילים

יתרונות שיקום משאבים

תהליכי טיפול מודרניים בשפכים שומניים מאפשרים שחזור של הידראקربונים יקרי ערך שניתן לשלב מחדש במחזורי ייצור. היבט זה של שיקום המשאבים הופך את מה שפעם נחשב לפסולת לנכסים יקרים, ומייצר מקורות הכנסה חדשים לתעשייה, ובמקביל מפחית את ההשפעה על הסביבה. החומרים השמורים עומדים לעיתים קרובות בתקני איכות גבוהים, ويمكن להשתמש בהם ביישומים שונים.

היתרונות הכלכליים מתרחבים מעבר לשיקום ישיר של משאבים. חברות המטמינות פתרונות טיפול יעילים חווים לעתים קרובות הפחתה בעלויות סילוק, הוצאות נמוכות יותר להסכמה סביבתית, ושיפור ביעילות התפעולית. יתרונות אלו הופכים את ההשקעה בטיפול מתאים בשפכים שומניים לא רק להכרח סביבתי, אלא גם להחלטת עסקים מוצלחת.

עמידה ברגולציה והפחתת סיכונים

בשל חומקן של הוראות סביבתיות ברחבי העולם, טיפול תקני בשפכים שמנוניים עוזר לארגונים לשמור על התאמתם ולמנוע קנסות כבדי משקל. השקעה בפתרונות טיפול יעילים מדגימה אחריות תאגידית ובעת עמידה מפני סיכונים משפטיים וסיכון לדימוי הקשורים להפרות סביבתיות.

חברות מחשבות קדימה מבינות שהשקעה פרואקטיבית בטכנולוגיות טיפול מתקדמות מספקת יתרונות לטווח הארוך. גישה זו לא רק מבטיחה התאמה נORMATיבית אלא גם ממצבת את הארגונים כמובילי דרך סביבתיים בתעשיותיהם.

מגמות עתידיות בניהול שפכים

חדשנות טכנולוגית

העתיד של טיפול בשפכים שומניים מתעצב על ידי טכנולוגיות חדשות כגון בינה מלאכותית ולמידת מכונה. חדשנות זו מאפשרת שליטה מדויקת יותר בתהליכי הטיפול, אופטימיזציה של היעילות וצמצום עלות הפעילות. חיישנים חכמים ומערכות אוטומטיות מהפכנים את האופן שבו פועלים מתקני טיפול, מבטיחים איכות עקיבה ומצמצמים טעויות אנוש.

המחקר נמשך אל תחומי טיפול חדשים, כולל תהליכים ביולוגיים מתקדמים ויישומים של ננוטכנולוגיה. התפתחויות חדישות אלו מבטיחות להפוך את טיפול השפכים השומניים ליעיל יותר, ידידותי לסביבה וריאלי כלכלית יותר מעולם.

שיטות עיבוד בר-קייימא

התעשייה מתמקדת יותר ויותר בפיתוח פתרונות טיפול בני קיימא אשר ממזערים את צריכת האנרגיה ומפחיתים את טביעת הרגל הפחמנית. שילוב של מקורות אנרגיה מתחדשים ויישום עקרונות של כלכלה מעגלית הופכים לנהלים סטנדרטיים במתקני טיפול מודרניים. התקדמויות אלו מבטיחות שהיתרונות הסביבתיים של הטיפול חורגים מעבר לניהול פסולת לקיימות אקולוגית כוללת.

חדשנות בשיטות עיבוד ברות קיימא ממשיכה לדחוף שיפורים ביעילות הטיפול תוך צמצום ההשפעה הסביבתית. התפתחות זו לקראת טכנולוגיות ירוקות יותר מייצגת את עתיד עיבוד החומת השמנונית, ומבטיחה תוצאות טובות יותר הן לתעשייה והן לסביבה.

שאלות נפוצות

מה גורם לחומת השמנונית להיות מזיקה במיוחד לסביבה?

שפשות שמנוני מכיל תערובת מורכבת של תרכובות רעילות, כולל מתכות כבדות, הידראקרבונים וחומרים מסוכנים אחרים שיכולים להתקיים בסביבה במשך עשורים. חומרים אלו יכולים לפגוע במשאבי קרקע ומים, לפגוע בחיות הבר וליצור סיכונים חמורים לבריאות האדם באמצעות חשיפה ישירה או זיהום מקורות מזון ומים.

מה משך זמן עיבוד שפשות השמנוני?

משך הזמן של עיבוד שפשות שמנוני משתנה בהתאם לשיטת העיבוד שנבחרה ולמאפייני השפשות. עיבודים כימיים ופיזיקליים עשויים להימשך מספר שעות עד ימים, בעוד שיטות עיבוד ביולוגיות עלולות להימשך מספר שבועות. טכנולוגיות מתקדמות הפחיתו בצורה ניכרת את זמני העיבוד תוך שיפור יעילות העיבוד.

אילו הן השיטות האפקטיביות ביותר לטיפול בשפשות שמנוני?

גישות הטיפול באספלת שמן הנותנת תוצאות אפקטיביות ביותר משלבות לרוב מספר שיטות, כולל הפרדה פיזיקלית, טיפול כימי ועיבוד תרמי. בחירת שיטת הטיפול תלויה בגורמים שונים כגון הרכב האספלה, הנפח והמוצרים הסופיים הרצויים. מתקנים מודרניים משתמשים לעתים קרובות במערכות משולבות שמטרתן למקסם את איסוף המשאבים תוך הבטחת הגנה על הסביבה.