systém na čistenie nádrží ropařských polí

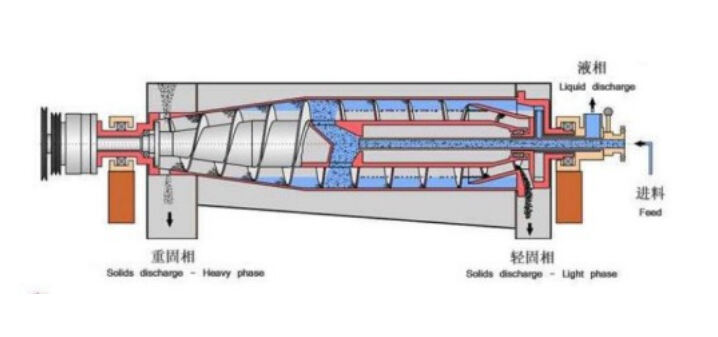

Systém na čistenie nádrží v ropnom priemysle predstavuje inovatívne riešenie pre údržbu a servisovanie nádrží v ropy a plynárskom priemysle. Tento pokročilý systém kombinuje automatizovanú technológiu s presnou inžinieriou, aby efektívne odstránil sediment, blátka a iné nánosy, ktoré sa sčasom nahromadzujú v ukladacích nádržiach. Systém používa vysokotlaké vodné trysky a špecializované čistiacie hlavy, ktoré môžu dosiahnuť každý kút nádrže, čo zabezpečí dôkladné čistenie s minimálnym ľudským zásahom. Táto technológia je osobitne cenná tým, že dokáže čistiť nádrže s úbytkom doby nečinnosti a zachovávaním bezpečnostných štandardov. Systém má možnosti vzdialenej operácie, čo umožňuje technikom monitorovať a riadiť čistiaci proces z bezpečnej vzdialenosti. Inkorporuje pokročilé filtračné a spracovávacie komponenty odpadu, ktoré oddelujú a zbierajú látky,ľahko uskutočňujúc ich správne vyhodenie a dodržiavajúc ekologické normy. Zariadenie je navrhnuté tak, aby bolo schopné spracovať rôzne veľkosti a konfigurácie nádrží, čo ho robí univerzálne pre rôzne aplikácie v ropnom poli. Okrem toho systém obsahuje sofistikované senzory a monitorovaciu techniku, ktoré poskytujú aktuálnu spätnú väzbu o priebehu čistenia a stave nádrže, čo zabezpečuje optimálne výsledky čistenia a zároveň udržiava operačnú efektivitu.