Улога напредне технологије у индустријском одржавању

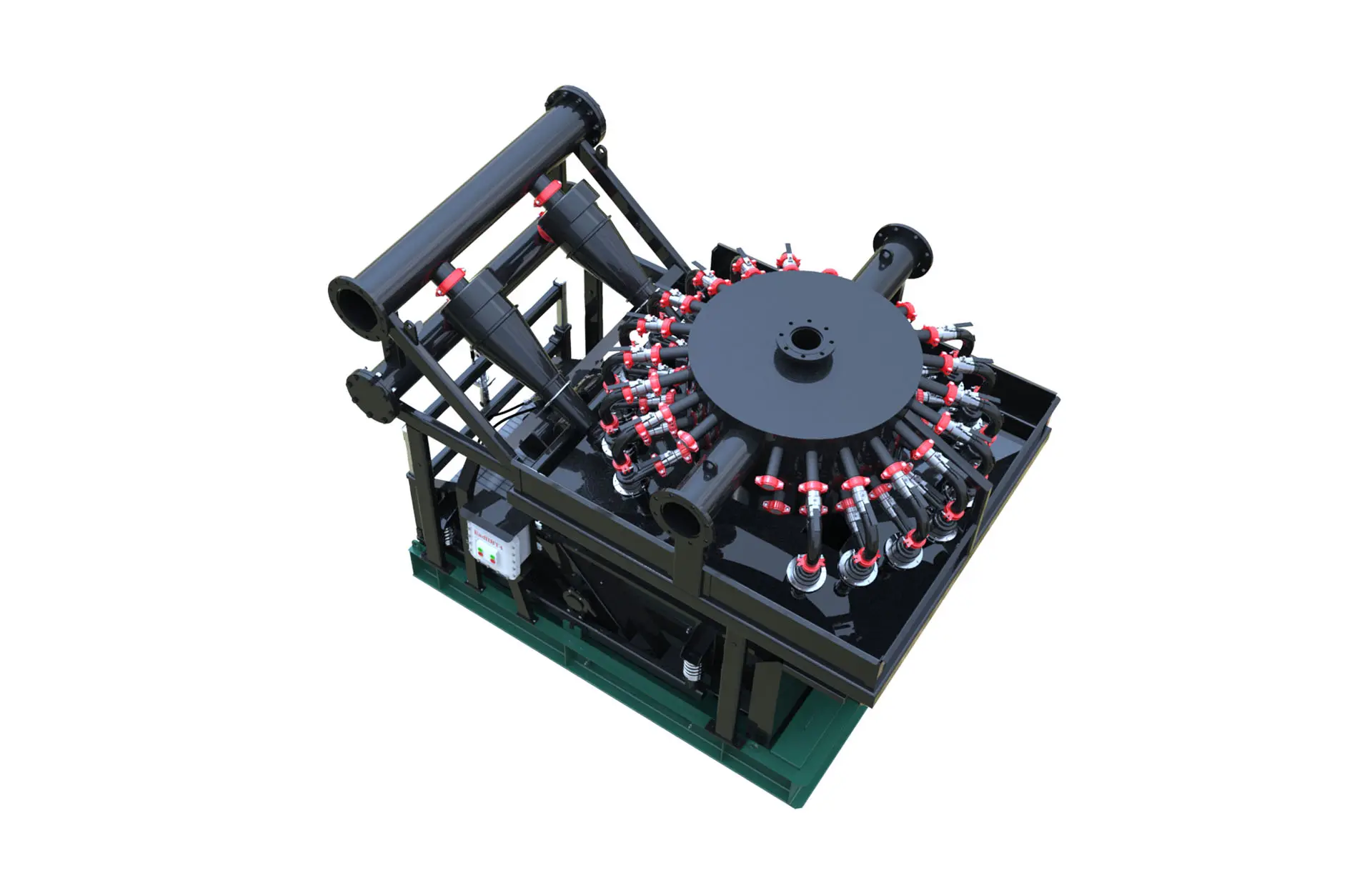

Индустријски објекти данас захтевају ефикасност, безбедност и сталан рад у свим операцијама. Резервоари који се користе за складиштење у индустријама као што су хемијска, прерада хране, нафта и гас, и третман воде морају остати чисти да би се осигурали поузданост и усклађеност. Само ручни методи чишћења често доводе до продуженог простоја, безбедносних ризика и неповезаних резултата. Oprema za automatsko čišćenje cisterna je transformisao način na koji organizacije izvode održavanje, pružajući moderno rešenje koje kombinuje brzinu i preciznost. Minimiziranjem ručnog intervenisanja, optimizacijom korišćenja resursa i osiguravanjem temeljnog čišćenja, oprema za automatsko čišćenje rezervoara postala je neophodna investicija za kompanije koje se fokusiraju na kvalitet i efikasnost.

Ključne prednosti opreme za automatsko čišćenje rezervoara

Poboljšana efikasnost u operacijama čišćenja

Jedna od najistaknutijih prednosti opreme za automatsko čišćenje rezervoara je njena sposobnost da završi zadatke brže u odnosu na ručne metode. Tradicionalno čišćenje može zahtevati timove radnika i dugo pripremno vreme. Automatski sistemi, s druge strane, dizajnirani su tako da rade kontinuirano i obavljaju složene zadatke čišćenja uz minimalnu nadgledanje. Ova efikasnost ne samo da smanjuje vreme prostoja, već omogućava preduzećima da planiraju održavanje bez velikih prekida u svakodnevnim operacijama.

Smanjenje potrebe za ručnim radom

Ručno čišćenje rezervoara je naporan posao i često opasan. Radnici moraju ulaziti u ograničene prostore, izlažući se hemikalijama, gasovima i fizičkim rizicima. Oprema za automatsko čišćenje rezervoara eliminira većinu ovih opasnosti preuzimajući zadatke koji su ranije zahtevali ljudsko prisustvo unutar rezervoara. Rezultat je bezbednije radno okruženje i smanjena zavisnost od velikih održavajućih ekipa. Kompanije mogu ponovo rasporediti svoje zaposlene na strateškije pozicije, dok istovremeno obezbeđuju temeljito i pouzdano čišćenje rezervoara.

Sigurnosne prednosti opreme za automatsko čišćenje rezervoara

Smanjenje izloženosti radnika opasnostima

Безбедност је највиши приоритет у индустријама које се баве хемикалијама, горивима или другим опасним материјама. Ручно чишћење резервоара често подразумева рад у затвореним просторима, што представља озбиљне ризике по здравље и безбедност. Опрема за аутоматско чишћење резервоара смањује или потпуно елиминише потребу за присуством људи унутра, држећи запослене ван штетних средина. Ово драматично смањује могућност несрећа, излагања хемикалијама и других безбедносних инцидената.

Usklađenost sa industrijskim standardima

Пракса прописане регулаторике је још једна кључна област у којој опрема за аутоматско чишћење резервоара доноси користи. Многе индустрије морају да поштују строге стандарде здравља и безбедности у одржавању резервоара. Аутоматски системи не осигуравају само да резервоари испуњавају стандарде чistoће, већ такође дају конзистентне и проверљиве резултате. Коришћењем опреме за аутоматско чишћење резервоара, компаније могу самопоуздано да прођу контроле и ревизије, истовремено показујући преданост применi најбољих пракси у безбедности на радном месту.

Економичност опреме за аутоматско чишћење резервоара

Мање трошкове одржавања

Често ручно чишћење често доводи до оштећења опреме, неефикасног коришћења ресурса и сталних трошкова поправке. Опрема за аутоматско чишћење резервоара дизајнирана је да смањи хабање површина резервоара и оптимизује циклусе чишћења. То резултира мање поправки и дужим веком трајања како резервоара тако и система за чишћење. Током времена, уштеде постају значајне, због чега аутоматизација представља финансијски исплативу инвестицију.

Оптимизовано коришћење ресурса

Још једна финансијска предност опреме за аутоматско чишћење резервоара је ефикасно коришћење средстава за чишћење, воде и енергије. Ручне методе могу довести до губитка ресурса услед људске грешке или неравномерне примене. Аутоматизовани системи користе прецизно контролисане процесе, осигуравајући да се користи само неопходна количина ресурса. За компаније које управљају више резервоара или великим објектима, ова ефикасност се преводи у значајне уштеде.

Универзалност опреме за аутоматско чишћење резервоара

Prilagodljivost u različitim industrijama

Опрема за аутоматско чишћење резервоара није ограничена само на једну индустрију. Подједнако је ефикасна у производњи хране и пића, фармацеутској индустрији, петрохемијској индустрији и пречишћавању отпадних вода. Свака индустрија има свој скуп изазова, али аутоматски системи се могу прилагодити да задовоље специфичне захтеве. Ова вишеструкост чини опрему за аутоматско чишћење резервоара вредном имовином за компаније које раде у различитим секторима.

Рад са различитим величинама и конфигурацијама резервоара

Резервоари долазе у различитим облицима и величинама, а неки представљају значајне изазове у чишћењу. Опрема за аутоматско чишћење резервоара конструисана је тако да се прилагоди различитим конструкцијама резервоара, од малих складишних јединица до огромних индустријских контейнера. Без обзира да ли су у питању остатаци, седименти или затврдели талози, аутоматски системи обезбеђују сталне резултате чишћења. Ова прилагодљивост осигурава да компаније могу користити једно решење на више примене без компромиса у ефикасности.

Утицај на животну средину аутоматске опреме за чишћење резервоара

Смањење отпадних вода и загађења

Одлучујући фактор у свим индустријама је постало питање одрживости, а аутоматска опрема за чишћење резервоара има позитиван ефекат тако што смањује количину отпадних вода и загађења. Аутоматски системи су прецизни у приступу чишћењу, користећи мање воде и хемикалија у поређењу са ручним методама. Ово не само што штити животну средину, већ такође смањује терет третмана и одлагања отпадних вода.

Подршка одрживим пословним праксама

Компаније се све чешће процењују на основу својих еколошких перформанси. Аутоматска опрема за чишћење резервоара подудара се са циљевима одрживости тако што минимизира употребу ресурса и смањује емисије повезане са ручним чишћењем. Привредне организације које усвајају оваква решења могу појачати свој имиџ као одговорних према животној средини, истовремено испуњавајући и прописане регулаторне захтеве.

Поверење у рад аутоматске опреме за чишћење резервоара

Конзистентни и поновљиви резултати

Konstantnost je ključna karakteristika opreme za automatsko čišćenje rezervoara. Za razliku od ručnog čišćenja, koje može varirati u zavisnosti od veština i napora radnika, automatizovani sistemi svaki put obezbeđuju jednake rezultate. Ova konzistentnost osigurava da rezervoari ostanu u optimalnom stanju, smanjujući rizik od kontaminacije ili mehaničkih kvarova koji bi mogli prekinuti rad.

Produžen životni vek opreme

Čisti rezervoari manje su skloni koroziji, taloženju i oštećenjima. Oprema za automatsko čišćenje rezervoara pomaže u produženju veka trajanja samih rezervoara i sistema povezanih sa njima. Spominjanjem začepljenja i održavanjem glatke eksploatacije, ovi sistemi štite integritet infrastrukture i smanjuju učestalost skupih zamena.

Често постављана питања

Zašto je oprema za automatsko čišćenje rezervoara važna za industriju

Oprema za automatsko čišćenje rezervoara osigurava temeljno, efikasno i bezbedno čišćenje skladišnih rezervoara, smanjujući prostoje, zaštićujući radnike i poboljšavajući pouzdanost rada.

Kako oprema za automatsko čišćenje rezervoara štedi novac

Optimizacijom korišćenja resursa i smanjenjem ručnog rada, oprema za automatsko čišćenje rezervoara smanjuje troškove održavanja, minimizira potrebu za popravkama i produžava vek trajanja rezervoara.

Koje industrije najviše imaju koristi od opreme za automatsko čišćenje rezervoara

Industrije kao što su prehrambena i pića, petrohemijska, farmaceutska i obrada vode u velikoj meri se oslanjaju na opremu za automatsko čišćenje rezervoara zbog njezine prilagodljivosti i konzistentnih rezultata.

Može li oprema za automatsko čišćenje rezervoara poboljšati bezbednost na radnom mestu

Da, oprema za automatsko čišćenje rezervoara minimizira ulazak ljudi u ograničene prostore i smanjuje izloženost opasnim materijalima, čime značajno povećava bezbednost na radnim mestima.

Садржај

- Улога напредне технологије у индустријском одржавању

- Ključne prednosti opreme za automatsko čišćenje rezervoara

- Sigurnosne prednosti opreme za automatsko čišćenje rezervoara

- Економичност опреме за аутоматско чишћење резервоара

- Универзалност опреме за аутоматско чишћење резервоара

- Утицај на животну средину аутоматске опреме за чишћење резервоара

- Поверење у рад аутоматске опреме за чишћење резервоара

- Често постављана питања