Importance of Reliable Solutions in Industrial Operations

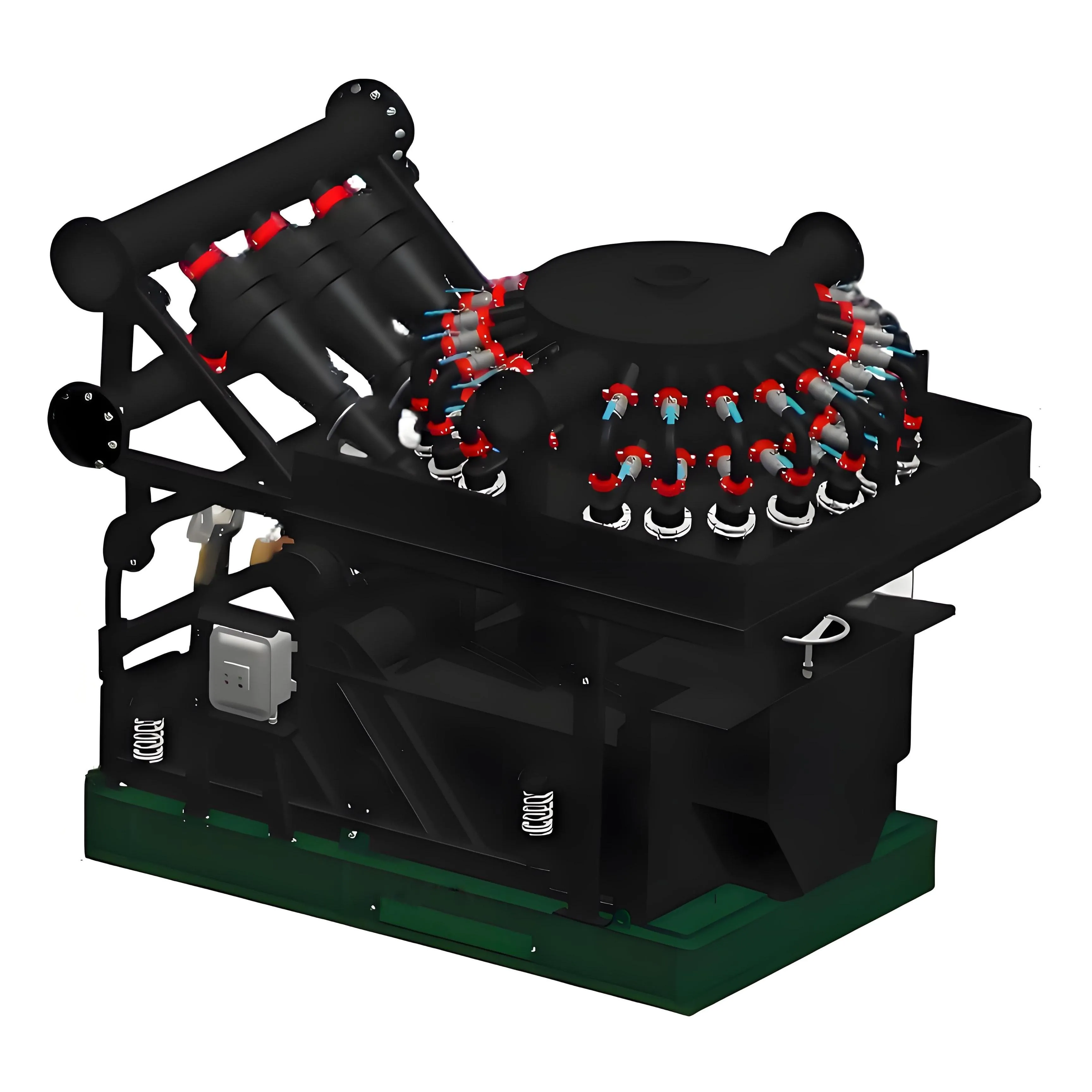

In industries that deal with drilling, waste management, and heavy fluid processing, solid control is one of the most demanding applications. Tanks used in these processes must be cleaned regularly to prevent buildup, contamination, and operational downtime. Relying on manual cleaning can be inefficient and dangerous, while modern solutions offer a safer and more reliable option. Automated Tank Cleaning Equipment has become the preferred choice for many companies because it ensures efficiency, safety, and consistency. By selecting the right system, businesses can optimize their workflow, reduce costs, and protect both equipment and personnel.

Factors to Consider in Selecting Automated Tank Cleaning Equipment

Compatibility With Tank Design

Tanks come in a wide range of shapes, sizes, and internal structures. Automated Tank Cleaning Equipment must be compatible with these variables to deliver optimal results. Choosing the right system means ensuring that it can reach every corner and surface without leaving residues behind. Proper compatibility also reduces the need for multiple cleaning passes, saving both time and resources.

Performance Under Harsh Conditions

Solid control applications often involve abrasive materials, sludge, and high-viscosity fluids. Automated Tank Cleaning Equipment must be robust enough to handle these challenging environments. Systems that can maintain consistent pressure and flow deliver reliable cleaning even under tough conditions. This ensures uninterrupted operations and prevents unexpected downtime caused by equipment failure.

Efficiency Benefits of Automated Tank Cleaning Equipment

Reducing Operational Downtime

Every minute of downtime can translate into significant financial loss in industrial operations. Automated Tank Cleaning Equipment reduces cleaning time and allows tanks to return to service quickly. By minimizing the interruption of critical processes, companies maintain steady productivity.

Optimizing Resource Usage

Manual cleaning often wastes water, cleaning agents, and energy. Automated Tank Cleaning Equipment is engineered to use resources efficiently, delivering precise cleaning with minimal waste. This optimization contributes to both cost savings and sustainable operations across industries.

Safety Advantages of Automated Tank Cleaning Equipment

Eliminating Confined Space Entry

One of the biggest risks in tank maintenance is sending workers into confined spaces filled with hazardous materials. Automated Tank Cleaning Equipment eliminates the need for direct human entry, dramatically reducing the risk of accidents and exposure. This enhances workplace safety and aligns with industry safety standards.

Reducing Worker Fatigue and Injury

Manual cleaning of tanks can be physically exhausting and dangerous. Automated Tank Cleaning Equipment takes on the heavy-duty work, reducing the strain on human workers. As a result, companies experience fewer injuries, lower compensation claims, and improved employee morale.

Customization of Automated Tank Cleaning Equipment

Adaptability for Different Applications

Not all tanks are used in the same way, and solid control operations often involve a variety of fluids and residues. Automated Tank Cleaning Equipment can be customized to handle these unique requirements. This adaptability ensures that the same equipment can be applied across different sites and processes without compromising performance.

Integration With Existing Systems

Introducing new equipment into an existing workflow can be challenging. Automated Tank Cleaning Equipment designed for easy integration simplifies this process. By working seamlessly with pumps, pipelines, and control systems already in place, companies avoid unnecessary disruptions and maintain productivity.

Long-Term Value of Automated Tank Cleaning Equipment

Extending Equipment Lifespan

Regular and thorough cleaning prevents corrosion, buildup, and mechanical failures in tanks. Automated Tank Cleaning Equipment protects the integrity of tanks, extending their lifespan and reducing the need for costly replacements. Over the years, this adds significant value to the overall operation.

Supporting Sustainable Practices

Many industries are under pressure to adopt eco-friendly methods. Automated Tank Cleaning Equipment supports sustainability by using fewer resources and generating less waste compared to manual methods. This helps businesses achieve their environmental goals while also appealing to stakeholders and regulators.

Operational Reliability in Solid Control Applications

Consistent Cleaning Results

Consistency is crucial in solid control, where residue buildup can disrupt operations. Automated Tank Cleaning Equipment delivers uniform results every time, ensuring that tanks are always ready for use. This reliability reduces variability and provides confidence in day-to-day operations.

Improving Overall Productivity

When tanks are cleaned thoroughly and quickly, operations can continue without delays. Automated Tank Cleaning Equipment contributes to higher productivity levels by allowing businesses to focus on core tasks instead of extended maintenance. This improves efficiency across the entire production line.

FAQ

Why is Automated Tank Cleaning Equipment essential for solid control applications

Automated Tank Cleaning Equipment ensures tanks are cleaned safely and efficiently, reducing downtime and maintaining the reliability needed for demanding solid control operations.

How does Automated Tank Cleaning Equipment improve safety

By eliminating the need for confined space entry and reducing worker exposure to hazardous substances, Automated Tank Cleaning Equipment makes tank cleaning significantly safer.

What cost benefits come with Automated Tank Cleaning Equipment

Automated Tank Cleaning Equipment saves money by reducing resource waste, minimizing downtime, and extending the lifespan of tanks, leading to long-term financial advantages.

Can Automated Tank Cleaning Equipment be customized for different industries

Yes, Automated Tank Cleaning Equipment can be tailored to suit specific tank designs, fluid types, and operational requirements, making it versatile for multiple industries.

Table of Contents

- Importance of Reliable Solutions in Industrial Operations

- Factors to Consider in Selecting Automated Tank Cleaning Equipment

- Efficiency Benefits of Automated Tank Cleaning Equipment

- Safety Advantages of Automated Tank Cleaning Equipment

- Customization of Automated Tank Cleaning Equipment

- Long-Term Value of Automated Tank Cleaning Equipment

- Operational Reliability in Solid Control Applications

- FAQ