Introduction to Maintenance Tips for Automated Tank Cleaning Equipment

Why Regular Maintenance is Critical for Efficiency

Keeping automated tank cleaning gear in good shape makes all the difference when it comes to getting those tanks spotless. Well maintained machines work better and save money in the long run. Take a look at what some field data shows about this stuff. Companies that stick with regular checkups often see around 15% less energy going through their systems. And let's face it, nobody wants to replace expensive equipment before its time. Most facilities find that sticking with scheduled maintenance just makes sense for their bottom line. The equipment lasts longer, works smoother day after day, and everyone gets what they need without wasting resources on breakdowns or inefficiencies.

Impact of Neglecting Maintenance on Safety and Productivity

When companies skip regular maintenance on their automated tank cleaning gear, they're setting themselves up for serious problems that put workers at risk. The manufacturing industry has seen plenty of cases where equipment just stops working because nobody bothered to check it regularly, and these breakdowns often end up hurting people. Plus, when machines suddenly stop functioning, factories lose precious time and money. We've all heard stories about plants losing tens of thousands each hour during unplanned shutdowns. That's why smart businesses make sure their maintenance schedules stay current. A good preventive maintenance program keeps everyone safer while avoiding those costly production halts. Simple weekly inspections and following manufacturer guidelines go a long way toward keeping operations running smoothly without surprises.

Regular Inspections for Automated Tank Cleaning Equipment

Inspecting Nozzles and Spray Systems for Blockages

Keeping automated tank cleaning gear running smoothly really depends on regular inspections, especially looking at those nozzles and spray systems up close. Blockages in these parts can totally mess up how well the equipment cleans tanks. Most technicians know this firsthand after dealing with clogged nozzles during maintenance calls. Industry guidelines actually suggest checking spray patterns every few weeks to make sure surfaces get proper coverage without gaps. The problem with blocked nozzles isn't just poor cleaning quality either. When something gets stuck, operators often end up running extra cleaning cycles just to be safe, and that adds hours onto their workday. Smart facilities set up monthly inspection schedules so maintenance teams can spot and fix these issues before they become bigger problems down the line.

Checking Seals, Gaskets, and Hoses for Wear

Checking seals, gaskets, and hoses for signs of wear can stop leaks before they happen, which keeps cleaning operations running smoothly and avoids dangerous situations on site. According to maintenance reports across various industries, around one third of all tank cleaning system breakdowns actually stem from worn out parts in these areas. When technicians perform routine checks, they spot problems early enough to replace components before major issues arise. Keeping an eye on these details maintains the whole system's reliability over time. For plant managers concerned about both safety records and downtime costs, regular inspection schedules make absolute sense for long term operations.

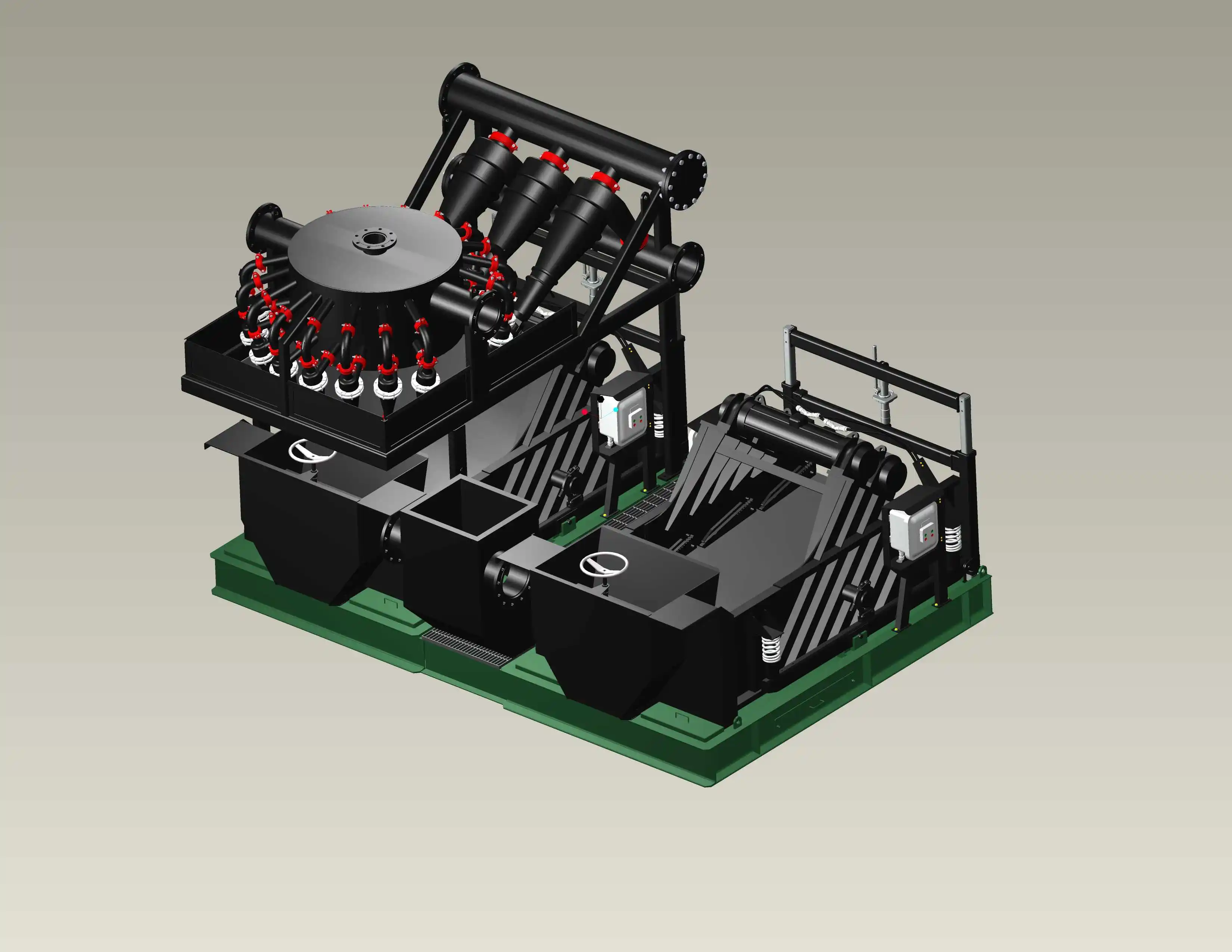

Evaluating Mechanical Components (Pumps, Motors, and Rotating Brushes)

Pumps, motors, and those spinning brush assemblies form the backbone of how automated tank cleaners actually work day to day. When these mechanical bits start showing signs of age, regular checkups become absolutely essential if we want to keep the cleaning job done right. Watch out for things like grinding sounds coming from the motor housing or when the system just takes forever to finish what it used to do quickly. These warning signals need fixing fast before something breaks down completely during critical operations. Keeping detailed records on every repair job and part swap helps track how healthy all those moving parts really are over time. Good documentation isn't just paperwork - it's gold when planning maintenance cycles, extending equipment life, and maintaining consistent performance across shifts.

Flushing the System to Remove Residual Chemicals

Regular flushing is really important when it comes to keeping automated tank cleaning equipment running at its best. When we talk about these flushing procedures, they basically get rid of leftover chemicals inside the tanks. If those chemicals stay put too long, they start causing problems like corrosion or buildup on internal parts. And trust me, this kind of buildup doesn't just sit there nice and quiet it actually starts messing with how well the whole system works over time. Most experts recommend doing a full flush right after each cleaning cycle, something manufacturers usually back up in their manuals too. Skipping this step might seem like a small thing but it leads to bigger issues down the road. Systems that aren't properly flushed tend to break down more often, which means higher repair bills and more downtime for maintenance crews.

Cleaning Exterior Surfaces to Prevent Corrosion

Keeping the outside of automated tank cleaning systems clean helps stop corrosion from getting started. When corrosion takes hold, it eats away at materials, weakens the structure of the equipment, and cuts down how long it will last before needing replacement. Regular surface cleaning should be part of any good maintenance routine because it stops all those problems plus makes the workplace safer for everyone involved. Choosing the right kind of cleaner matters too since different materials react differently to various chemicals. Some cleaners actually help build up protection layers on metal surfaces while others might do more harm than good if used incorrectly. Making time for proper cleaning isn't just about looks either; it keeps the whole system running smoothly without unexpected breakdowns throughout its service life.

Lubricating Moving Parts for Smooth Operation

Keeping those moving parts properly greased is absolutely vital if we want our automated tank cleaners running smoothly and efficiently day after day. When done regularly, lubrication cuts down on friction across all those mechanical joints and bearings, making everything work better while at the same time protecting against premature wear on critical components. Most manufacturer manuals actually spell out exact intervals for when different parts need attention, so sticking to those guidelines really pays off in terms of how long the whole system lasts. Checking those lubrication spots during routine inspections isn't just good housekeeping either it helps spot early signs of leaks or other problems before they turn into major headaches. And let's face it nobody wants their production line grinding to a halt because some gear seized up from lack of proper maintenance.

Monitoring and Replacing Worn-Out Components

Tracking Lifespan of High-Wear Parts (Filters, Bearings)

Detailed records about how long parts that wear out fast actually last before needing replacement are really important for planning maintenance ahead of time. When we keep track of these numbers, it helps stop machines from breaking down unexpectedly because we know exactly when to swap out worn components. Research indicates that regular monitoring cuts down on surprise breakdowns somewhere around 25 percent, which makes systems run smoother overall. For those looking to make their maintenance work easier, there are inventory systems available now that will send alerts when parts need replacing soon. These tools help ensure everything stays running properly without constant guesswork involved.

Identifying Signs of Component Degradation

Spotting the early warning signals when parts start to wear out helps prevent bigger headaches down the road that cost money in repairs and lost production time. Things like strange vibrations coming from machinery or when it starts running less efficiently are red flags pointing to deeper problems needing immediate action. Getting good diagnostic gear pays off because it makes finding these issues much quicker, which keeps machines performing better over time. When workers know what to look for during routine checks, they become part of the solution rather than just following orders. The savings add up fast too many plants report cutting maintenance expenses by almost half after implementing proper training programs for their teams.

Scheduling Timely Replacements to Avoid Downtime

Creating a maintenance plan around actual usage data helps keep equipment running smoothly over its entire life cycle. Studies show replacing parts before they fail saves businesses roughly 40% compared to dealing with breakdowns later on something most managers would rather avoid. When companies stick to regular replacement timelines, their cleaning operations stay reliable day after day because worn out components get swapped out long before they cause problems. The bottom line? A good preventive maintenance strategy keeps systems working efficiently for years instead of constantly fixing what breaks down unexpectedly.

Calibration and Testing for Optimal Performance

Verifying Spray Patterns and Coverage Consistency

Getting those spray patterns calibrated on a regular basis makes all the difference when it comes to applying cleaning solutions evenly across surfaces without leaving spots untouched. When we run tests carefully enough, we spot those little inconsistencies early on so adjustments happen before they become real problems for our cleaning crews. Research shows that getting this calibration right actually increases how effective cleaning becomes by around 20 percent. That kind of improvement matters a lot in facilities where cleanliness standards need to stay consistently high day after day.

Testing Pressure Settings and Flow Rates

Regular checks and tweaks to pressure settings and flow rates really matter when keeping automated tank cleaning systems running at their best. Most manufacturers come with clear instructions about what works best for their equipment. Ignore these recommendations and things can go wrong fast either with poor cleaning results or actual damage to both the system itself and whatever tanks it's working on. From what we've seen in practice, sticking to those suggested flow rates makes a big difference. Not only does it clean better, but it also means less strain on all those moving parts inside the machinery, which naturally extends how long everything lasts before needing replacement.

Ensuring Proper Function of Automation Systems

Regular maintenance of automation systems is essential if we want those programmed functions to work properly and keep things running efficiently. Fixing problems quickly cuts down on breakdown risks and keeps operations flowing smoothly without interruptions. Most professionals recommend updating software regularly and doing routine diagnostics to maintain top performance from automated equipment, something really important for keeping everything working as intended. These maintenance habits do more than just ensure consistent results they actually help build reliable systems over time, which matters a lot in tank cleaning where downtime can be costly and disruptions unacceptable.

FAQ

1. Why is regular maintenance crucial for automated tank cleaning equipment?

Regular maintenance ensures that automated tank cleaning equipment operates at peak efficiency, reducing operational costs and extending equipment life, which enhances return on investment (ROI).

2. What risks arise from neglecting maintenance?

Neglecting maintenance can lead to critical equipment failures, posing safety risks to operators and causing increased downtime, which can significantly impact productivity and revenue.

3. How often should the system be flushed?

Best practices recommend flushing the system after every cleaning cycle to prevent chemical buildup and maintain optimal performance.

4. What are the signs of component degradation?

Signs include unusual vibrations or decreased efficiency, indicating the need for prompt attention to avoid larger problems and costly downtime.

Table of Contents

- Introduction to Maintenance Tips for Automated Tank Cleaning Equipment

-

Regular Inspections for Automated Tank Cleaning Equipment

- Inspecting Nozzles and Spray Systems for Blockages

- Checking Seals, Gaskets, and Hoses for Wear

- Evaluating Mechanical Components (Pumps, Motors, and Rotating Brushes)

- Flushing the System to Remove Residual Chemicals

- Cleaning Exterior Surfaces to Prevent Corrosion

- Lubricating Moving Parts for Smooth Operation

- Monitoring and Replacing Worn-Out Components

- Calibration and Testing for Optimal Performance

- FAQ