The Role of Advanced Technology in Industrial Maintenance

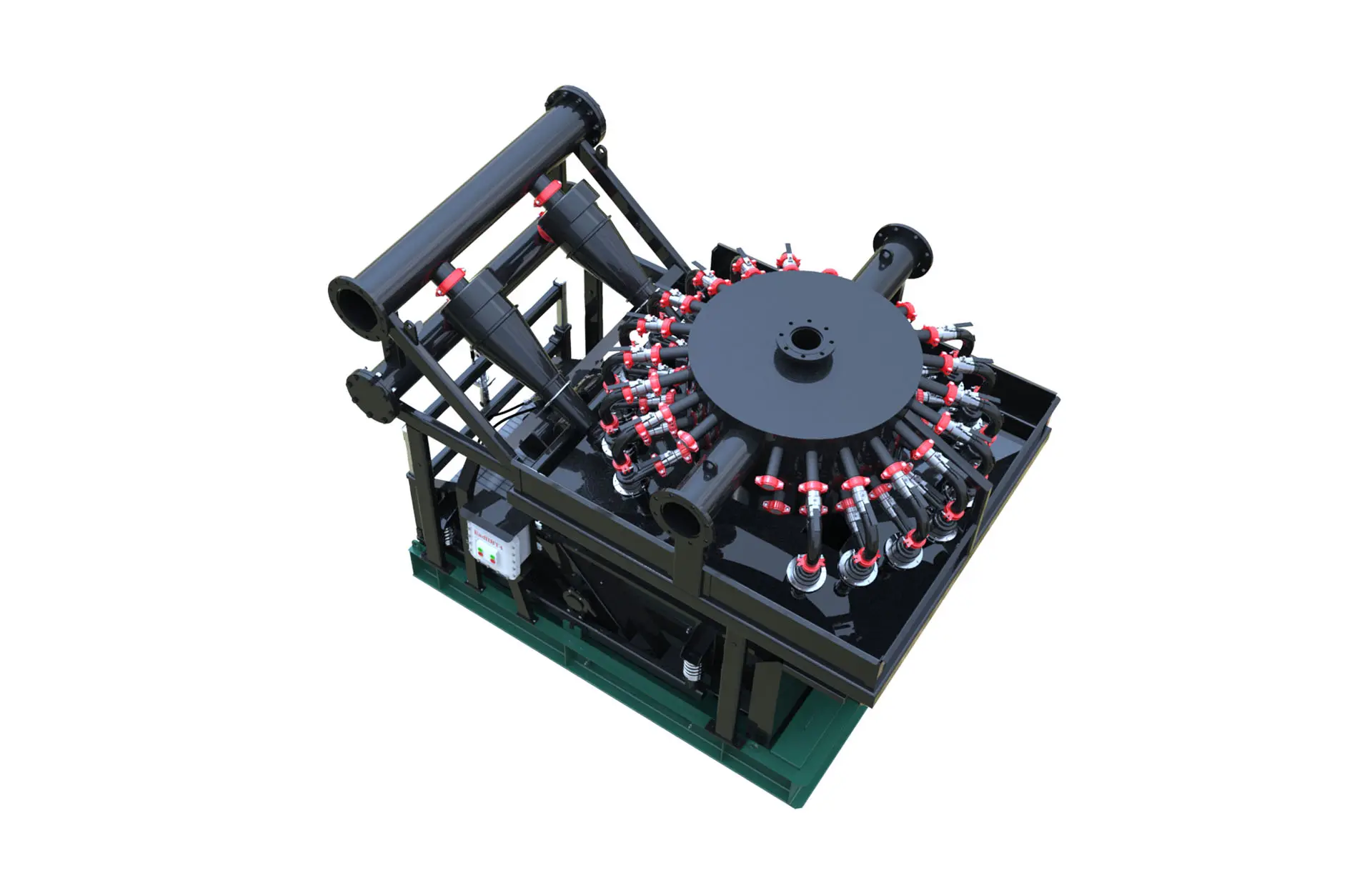

Industrial facilities today demand efficiency, safety, and consistent performance across all operations. Tanks used for storage in industries such as chemicals, food processing, oil and gas, and water treatment must remain clean to ensure reliability and compliance. Relying solely on manual cleaning methods often leads to extended downtime, safety hazards, and inconsistent results. Automated Tank Cleaning Equipment has transformed the way organizations handle maintenance, providing a modern solution that combines speed with accuracy. By minimizing manual intervention, optimizing resource use, and guaranteeing thorough cleaning, Automated Tank Cleaning Equipment has become an essential investment for companies focused on quality and efficiency.

Key Benefits of Automated Tank Cleaning Equipment

Improved Efficiency in Cleaning Operations

One of the standout advantages of Automated Tank Cleaning Equipment is its ability to complete tasks more quickly than manual methods. Traditional cleaning may require teams of workers and long hours of preparation. Automated systems, on the other hand, are designed to operate continuously and handle complex cleaning tasks with minimal oversight. This efficiency not only reduces downtime but also allows businesses to schedule maintenance without major disruptions to daily operations.

Reduction in Manual Labor Requirements

Manual tank cleaning is labor-intensive and often dangerous. Workers must enter confined spaces, exposing themselves to chemicals, gases, and physical risks. Automated Tank Cleaning Equipment eliminates most of these hazards by taking over the tasks that once required human presence inside tanks. The result is a safer work environment and reduced dependence on large maintenance crews. Companies can reallocate their staff to more strategic roles while ensuring tanks are cleaned thoroughly and reliably.

Safety Advantages of Automated Tank Cleaning Equipment

Minimizing Worker Exposure to Hazards

Safety is a top priority in industries dealing with chemicals, fuels, or other hazardous substances. Manual tank cleaning often involves confined space entry, which poses serious health and safety risks. Automated Tank Cleaning Equipment reduces or completely removes the need for human entry, keeping workers away from harmful environments. This dramatically lowers the chances of accidents, chemical exposure, and other safety incidents.

Compliance With Industry Standards

Regulatory compliance is another critical area where Automated Tank Cleaning Equipment offers value. Many industries are required to follow strict health and safety standards regarding tank maintenance. Automated systems not only ensure that tanks meet cleanliness standards but also generate consistent, verifiable results. By using Automated Tank Cleaning Equipment, companies can confidently pass inspections and audits while demonstrating a commitment to best practices in workplace safety.

Cost-Effectiveness of Automated Tank Cleaning Equipment

Lower Maintenance Costs

Frequent manual cleaning often leads to equipment damage, inefficient use of resources, and recurring repair costs. Automated Tank Cleaning Equipment is designed to minimize wear and tear on tank surfaces while optimizing cleaning cycles. This results in fewer repairs and a longer lifespan for both tanks and cleaning systems. Over time, the cost savings become substantial, making automation a financially sound investment.

Optimized Resource Consumption

Another financial benefit of Automated Tank Cleaning Equipment is the efficient use of cleaning agents, water, and energy. Manual methods may waste resources due to human error or uneven application. Automated systems use precisely controlled processes, ensuring that only the necessary amount of resources is used. For companies managing multiple tanks or large facilities, this efficiency translates into significant savings.

Versatility of Automated Tank Cleaning Equipment

Adaptability Across Industries

Automated Tank Cleaning Equipment is not limited to a single industry. It is equally effective in food and beverage manufacturing, pharmaceuticals, petrochemicals, and wastewater treatment. Each industry has its own set of challenges, but automated systems can be customized to meet specific requirements. This versatility makes Automated Tank Cleaning Equipment a valuable asset for companies operating across different sectors.

Handling Various Tank Sizes and Configurations

Tanks come in different shapes and sizes, and some present significant cleaning challenges. Automated Tank Cleaning Equipment is engineered to adapt to different tank designs, from small storage units to massive industrial containers. Whether dealing with residues, sediments, or hardened deposits, automated systems deliver consistent cleaning results. This adaptability ensures that companies can use a single solution across multiple applications without compromising efficiency.

Environmental Impact of Automated Tank Cleaning Equipment

Reducing Wastewater and Contamination

Sustainability is a growing concern across industries, and Automated Tank Cleaning Equipment contributes positively by reducing wastewater and contamination. Automated systems are precise in their cleaning approach, using less water and fewer chemicals compared to manual methods. This not only protects the environment but also reduces the burden of wastewater treatment and disposal.

Supporting Sustainable Business Practices

Companies are increasingly evaluated on their environmental performance. Automated Tank Cleaning Equipment aligns with sustainability goals by minimizing resource use and reducing emissions associated with manual cleaning. Businesses that adopt such solutions can strengthen their reputation as environmentally responsible organizations while also meeting regulatory requirements.

Operational Reliability From Automated Tank Cleaning Equipment

Consistent and Repeatable Results

Consistency is a hallmark of Automated Tank Cleaning Equipment. Unlike manual cleaning, which may vary depending on worker skill and effort, automated systems deliver uniform results every time. This consistency ensures that tanks remain in optimal condition, reducing the risk of contamination or mechanical failures that could interrupt operations.

Extended Equipment Lifespan

Clean tanks are less prone to corrosion, buildup, and damage. Automated Tank Cleaning Equipment helps extend the lifespan of both tanks and the systems connected to them. By preventing blockages and maintaining smooth operations, these systems protect the integrity of infrastructure and reduce the frequency of costly replacements.

FAQ

Why is Automated Tank Cleaning Equipment important for industries

Automated Tank Cleaning Equipment ensures thorough, efficient, and safe cleaning of storage tanks, reducing downtime, protecting workers, and improving operational reliability.

How does Automated Tank Cleaning Equipment save costs

By optimizing resource use and reducing manual labor, Automated Tank Cleaning Equipment lowers maintenance costs, minimizes repair needs, and extends the lifespan of tanks.

What industries benefit most from Automated Tank Cleaning Equipment

Industries such as food and beverage, petrochemical, pharmaceutical, and water treatment rely heavily on Automated Tank Cleaning Equipment due to its adaptability and consistent results.

Can Automated Tank Cleaning Equipment improve workplace safety

Yes, Automated Tank Cleaning Equipment minimizes human entry into confined spaces and reduces exposure to hazardous materials, making workplaces significantly safer.

Table of Contents

- The Role of Advanced Technology in Industrial Maintenance

- Key Benefits of Automated Tank Cleaning Equipment

- Safety Advantages of Automated Tank Cleaning Equipment

- Cost-Effectiveness of Automated Tank Cleaning Equipment

- Versatility of Automated Tank Cleaning Equipment

- Environmental Impact of Automated Tank Cleaning Equipment

- Operational Reliability From Automated Tank Cleaning Equipment

- FAQ