Introduction: The Role of Automated Tank Cleaning in Solid Control Systems

Control systems for solids play a key role during drilling operations since they manage drilling fluids and handle waste materials effectively, something crucial for keeping things running smoothly and safely on site. Tank cleaning automation works hand in hand with these systems, taking care of residue buildup, sludge accumulation, and other contaminant problems inside storage tanks. This makes the whole operation cleaner and safer day to day. We see these kinds of tech solutions popping up more often in oil and gas sectors specifically, but also in mining and construction where equipment downtime costs money. The result? Better efficiency overall and less risk of system failures down the line when maintenance gets done properly.

Oil and Gas Industry: Streamlining Drilling Waste Management with Automated Tank Cleaning

Enhancing Efficiency in Drilling Mud Recovery

Tank cleaning systems that automate the process boost drilling mud recovery rates substantially, cutting down waste while making better use of resources across the oil and gas sector. When companies adopt such systems, they get much more value out of their drilling mud inventory. The results speak for themselves too. Industry data shows operations using automated solutions have seen recovery improvements sometimes reaching as high as 50 percent over older manual techniques. For operators dealing with tight margins, this kind of jump in performance makes all the difference between profitable operations and money losing ventures. Drilling mud recovery isn't just an environmental concern anymore it's become central to how successful companies manage their day to day operations in this competitive market.

Reducing Hazardous Manual Labor in Sludge Removal

Manual sludge removal remains one of the most dangerous tasks in oil and gas operations. Workers face constant exposure to harmful chemicals and work in extremely unsafe conditions inside storage tanks. Automation is changing all that though. Modern equipment including robotic arms and remote controlled systems can clean tanks without putting anyone near the sludge at all. According to recent industry data from OSHA inspections, companies using automated cleaning solutions saw injury rates drop by around 40% over three years. Beyond keeping workers safe, these systems actually improve productivity too since there's far less downtime when accidents happen less frequently. Many operators now consider automated solutions essential for both safety and business continuity reasons.

Compliance with Environmental Regulations

For oil and gas firms dealing with tough environmental rules around waste disposal, automated cleaning systems have become essential tools. Waste management isn't just good practice anymore it's required by law, and getting caught short could mean serious fines down the road. These automated setups help keep everything within regulatory bounds because they operate consistently and accurately, cutting down on environmental harm. The systems handle waste collection and disposal properly, stopping pollutants from leaking into surrounding areas and protecting local ecosystems. When companies adopt this kind of tech, they not only meet their compliance requirements but also boost overall operations. Plus, they sleep better at night knowing they're avoiding those costly legal headaches that come from non-compliance issues.

Mining Industry: Optimizing Tailings and Slurry Tank Maintenance

Automated Cleaning for High-Volume Slurry Systems

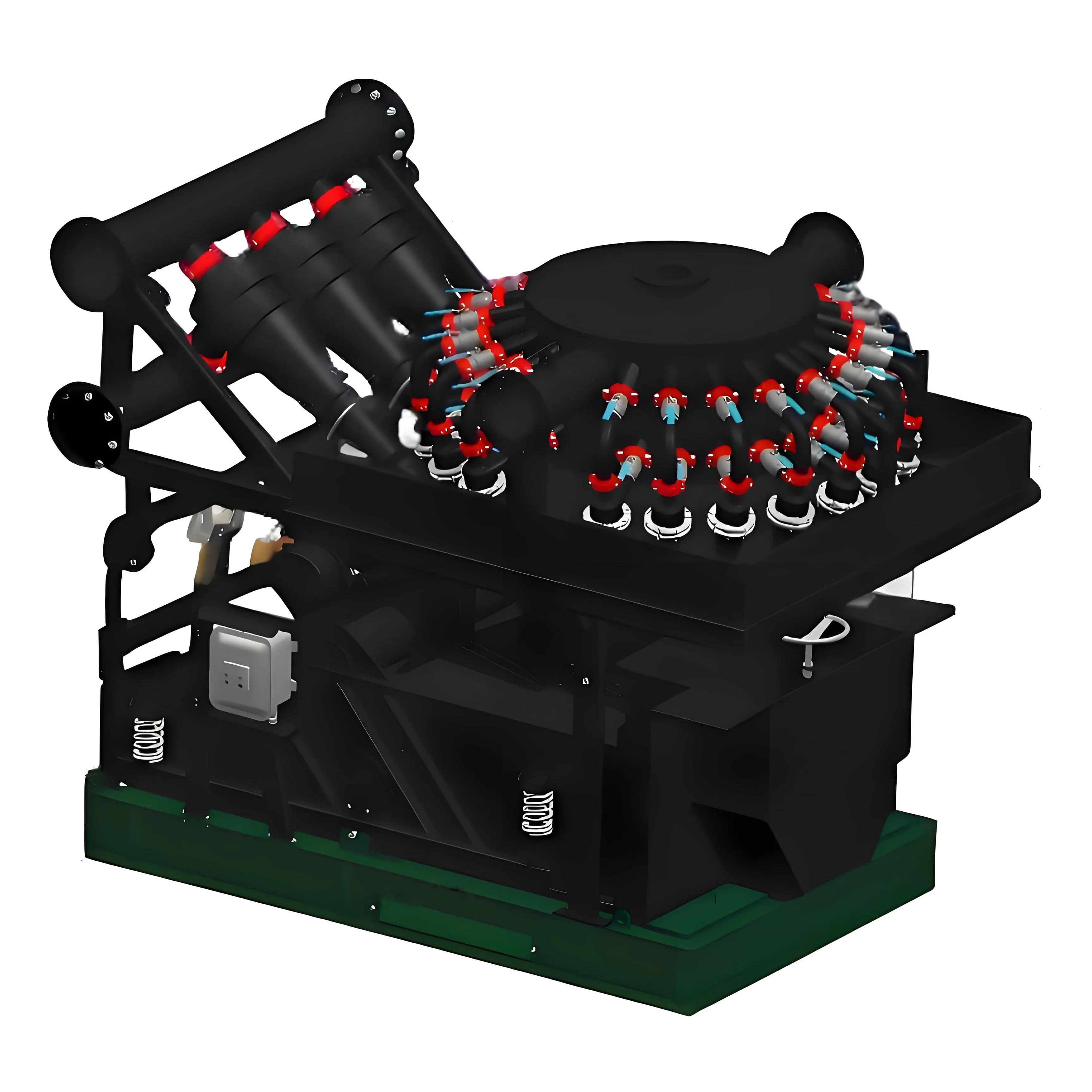

Tank cleaning automation makes all the difference when dealing with those massive slurry systems that just eat up time and resources. Take gold mines or coal processing plants for instance the slurry there gets so thick and heavy that regular cleaning just doesn't cut it anymore. Manual approaches simply can't keep up with the workload, which means wasted hours waiting for tanks to be cleared out before production can restart. Modern automated systems come packed with smart sensors and those robotic arms that move around inside tanks, hitting every corner consistently without fail. What these machines do best is reach into those awkward nooks and crannies where old buildup tends to hide, something human workers often overlook during their sweeps. Mines that have switched to this kind of setup report cutting down on maintenance stops by about 40%, according to recent field reports from several major operations across North America.

Preventing Cross-Contamination in Mineral Processing

Keeping cross contamination at bay during mineral processing matters a lot for maintaining product quality and running operations smoothly. Cleaning systems that are automated do wonders here because they provide structured cleaning routines which cut down on the chances of different materials getting mixed up between production runs. Real world testing shows clear advantages when these cleaning technologies get put into practice. Plants using automated systems often see better results in terms of product cleanliness while their overall processing speed picks up too. Take one facility that switched over to automated cleaning recently. They noticed fewer instances where contaminants messed up their products, so they had to reprocess things less frequently and ended up with much better quality outputs. For most manufacturers dealing with minerals day after day, investing in automation makes sense as it acts like insurance policy against unwanted contamination problems.

Cost Savings Through Reduced Downtime

Tank cleaning systems that are automated cut down on downtime during maintenance periods, which means better operational efficiency across the board. When cleaning gets streamlined, mining facilities can actually run longer hours between shutdowns while needing fewer breaks for maintenance work. Some studies point to real money saved through these efficiency gains, making automation an attractive option economically speaking. Less downtime translates into higher productivity rates, plus there's the added bonus of cutting back on labor expenses and resources typically needed for manual cleaning tasks. For mines looking to get more bang for their buck, investing in automated tank cleaning makes good sense financially when trying to make the most of available resources and boost bottom line profits.

Chemical Manufacturing: Safe and Efficient Cleaning for Hazardous Material Tanks

Minimizing Chemical Exposure Risks

When it comes to keeping workers safe around dangerous chemicals during cleanup operations, automated systems have become pretty essential. These setups use robots equipped with various sensors to handle tasks that used to be done by hand, which cuts down on the risk factors involved. For instance, instead of people having to deal directly with toxic spills, machines now do most of the dirty work. This approach actually fits right in with what organizations like OSHA and the EPA recommend regarding worker safety standards. Chemical manufacturing facilities find themselves in a better position when they invest in such tech solutions because not only does it protect employees, but it also helps them run their operations smoothly without compromising productivity levels.

Precision Cleaning for Reactive Substance Storage

Getting things really clean matters a lot when it comes to storing those reactive chemicals that show up all over chemical manufacturing facilities. These days, companies rely on stuff like special nozzles and automatic tank cleaners to hit those high cleaning standards needed to wipe away any leftover material that might start unwanted reactions down the line. The whole point of going so detailed with cleaning isn't just about following rules either. In actual chemical plants, sometimes tiny bits of contamination can turn into big safety problems later on. That's why investing in better cleaning tech makes sense for keeping storage tanks in good shape. When tanks stay properly cleaned, everyone wins really. Workers stay safer and there's less risk to the surrounding area too, which is pretty important considering what goes on inside those industrial sites daily.

Scaling Operations with Automated Workflows

In chemical manufacturing, automation really helps when companies want to grow bigger without spending tons more on labor. When factories automate their workflow, especially for things like cleaning processes, everything gets done quicker and safer at the same time. Take XYZ Chemicals as an example they expanded their production line last year after installing automated systems, and saw their output jump by 30% while accident rates dropped too. The bottom line is that bringing in automation doesn't just let plants produce more stuff it actually gives manufacturers a leg up when markets change suddenly. Companies that embrace these technologies tend to respond faster to what customers need next.

Wastewater Treatment: Revolutionizing Large-Scale Storage Tank Hygiene

Automated Systems for Biofilm and Sediment Removal

Wastewater treatment plants have seen major changes in how they keep tanks clean since automated systems came into play, especially when it comes to getting rid of stubborn biofilms and sediment buildup. Modern equipment now uses things like powerful water jets and spinning nozzles that actually work better at knocking down those tough layers of bacteria and debris. Cities that switched to automated cleaning report fewer problems with contaminated water because the tanks stay cleaner for longer periods. Some plant managers talk about seeing real differences after installation - one facility reported cutting maintenance downtime by almost half within six months. These improvements aren't just happening in big city treatment centers either; factories dealing with industrial waste are finding similar benefits across their operations.

Ensuring Compliance in Municipal and Industrial Treatment

Staying compliant with all those tough regulations around wastewater treatment remains absolutely essential, and that's where automated cleaning systems really shine. These setups keep track of everything happening during the cleaning process consistently while making sure all records are properly documented according to what environmental agencies require. With automation comes the ability to gather data instantly and generate reports automatically, something that matches exactly what regulators look for when checking compliance status. Environmental studies regularly point out that plants using such tech tend to stay on top of their compliance game much better than others. This leads to fewer headaches during inspections and builds confidence among communities who rely on both city and factory wastewater treatment facilities to do their job right without cutting corners.

Long-Term Maintenance Cost Reductions

Cleaning systems that work automatically can cut down on maintenance expenses over time because they require less manual work and allow for more frequent cleanings. These kinds of systems actually help protect equipment from damage during regular use, which means storage tanks last longer before needing replacement. Looking at actual numbers from companies that have made the switch, most find that while there's an upfront cost to install automation, it pays off handsomely through saved money on labor bills and fewer days when operations have to stop for cleaning. Many plants report seeing their maintenance spending drop after installation, something plant managers appreciate greatly since every dollar saved goes toward other improvements needed in their wastewater treatment facilities.

FAQs

What is automated tank cleaning?

Automated tank cleaning refers to a mechanized process for removing residues, sludge, and contaminants from storage tanks, using technologies like robotics and AI.

Why is automation important in tank maintenance?

Automation reduces human error, speeds up the cleaning process, minimizes environmental contamination risk, and significantly cuts labor costs.

How does automated cleaning aid the oil and gas industry?

In the oil and gas industry, automated cleaning enhances drilling mud recovery rates, reduces hazardous manual labor, and ensures compliance with environmental regulations.

What are the benefits of automation in mining and chemical manufacturing?

In mining, automation optimizes slurry system maintenance and prevents cross-contamination. In chemical manufacturing, it reduces chemical exposure risks, ensures precision cleaning, and scales operations.

How do automated cleaning systems impact wastewater treatment?

They effectively maintain large-scale tank hygiene, ensuring compliance with regulations, and significantly reduce long-term maintenance costs.

Table of Contents

- Introduction: The Role of Automated Tank Cleaning in Solid Control Systems

- Oil and Gas Industry: Streamlining Drilling Waste Management with Automated Tank Cleaning

- Mining Industry: Optimizing Tailings and Slurry Tank Maintenance

- Chemical Manufacturing: Safe and Efficient Cleaning for Hazardous Material Tanks

- Wastewater Treatment: Revolutionizing Large-Scale Storage Tank Hygiene

- FAQs