Understanding the Role of Mud Cooling Systems in Harsh Drilling Environments

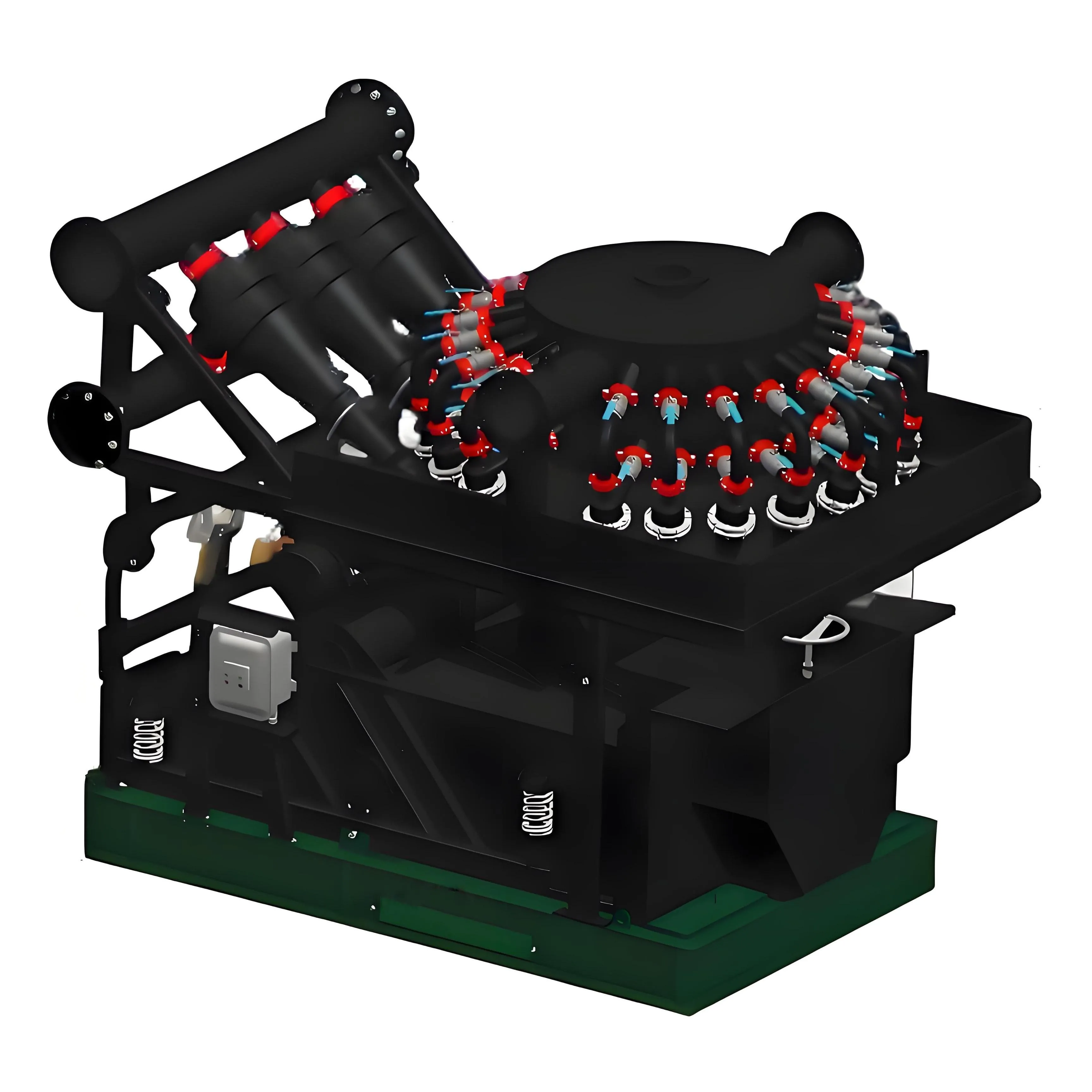

Mud cooling systems are essential in modern drilling operations, especially in geothermal or high-temperature oil and gas fields. These systems help manage downhole temperatures, reduce equipment wear, and improve the stability of the drilling fluid. Without an effective mud cooling system, the extreme heat encountered in deep drilling environments could compromise drilling performance and pose significant risks to both equipment and personnel.

A mud cooling system ensures that the drilling mud maintains its thermal and physical properties as it circulates through the wellbore. This cooling not only protects sensitive measurement tools but also enhances the overall efficiency of the drilling process. To better understand how these systems work, it’s important to break down the core components that make up a typical mud cooling system.

Core Structure of a Mud Cooling System

Heat Exchangers

Heat exchangers are at the heart of any mud cooling system. Their main function is to reduce the temperature of drilling mud by transferring heat to a secondary cooling medium, usually water or air. Plate heat exchangers and shell-and-tube heat exchangers are the two most commonly used types in these systems. Their efficiency and thermal transfer capabilities directly influence the effectiveness of the entire system.

Plate heat exchangers, due to their compact size and high surface area, are particularly effective in tight rig environments. On the other hand, shell-and-tube exchangers offer robustness and are suitable for operations requiring large-scale cooling. The selection of the heat exchanger depends on the operational requirements and the nature of the drilling site.

Pumps and Circulation Units

Pumps play a crucial role in ensuring the continuous flow of drilling mud through the mud cooling system. These pumps are specifically designed to handle high-temperature, high-viscosity fluids. The circulation units facilitate the movement of both the drilling mud and the cooling medium through the system.

Centrifugal pumps are typically preferred for their reliability and capability to handle abrasive fluids. The circulation system must be optimized to maintain a constant flow rate and prevent overheating or stagnation of the mud, which could affect the entire drilling operation.

Auxiliary Components That Enhance Performance

Cooling Towers

Cooling towers serve as external cooling sources that dissipate the heat extracted from the mud via the heat exchanger. They are particularly useful in land-based operations where ambient air can be effectively used to cool water that, in turn, cools the drilling mud.

Evaporative cooling towers are efficient at reducing temperatures in hot climates, while dry cooling towers are more suitable for environments where water conservation is a priority. Properly integrating a cooling tower into the mud cooling system can significantly improve the system’s overall thermal performance.

Temperature Sensors and Control Systems

Modern mud cooling systems incorporate advanced temperature sensors and automated control systems to maintain optimal thermal conditions. These sensors monitor the inlet and outlet temperatures of the drilling mud and adjust the flow rates accordingly.

Control systems allow for real-time adjustments to ensure consistent cooling and protect the integrity of the drilling mud. By integrating intelligent control mechanisms, operators can avoid thermal shocks, which could lead to material failure or inaccurate measurement readings.

Integration with Drilling Operations

Compatibility with Drilling Rigs

A well-designed mud cooling system must integrate seamlessly with existing drilling rigs. This includes considerations for spatial constraints, compatibility with rig power systems, and ease of installation. Modular systems offer greater flexibility and can be customized based on the size and type of the rig.

Such compatibility ensures minimal disruption to the drilling workflow and allows for faster deployment and maintenance of the cooling system. Companies offering modular and scalable mud cooling system solutions have a distinct advantage in high-temperature drilling markets.

Support for Geothermal and High-Temperature Wells

Geothermal drilling presents unique challenges due to the extreme temperatures encountered. A specialized mud cooling system is necessary to manage the high thermal loads and maintain the stability of the drilling fluid. This is critical for ensuring safe and efficient operations.

In high-temperature oil and gas wells, maintaining mud properties becomes increasingly difficult. By employing an advanced mud cooling system, operators can extend equipment life, ensure measurement accuracy, and reduce downtime caused by overheating.

Design and Engineering Considerations

Material Selection

The materials used in the construction of a mud cooling system must withstand high temperatures, corrosive fluids, and mechanical stress. Stainless steel, titanium, and specialized alloys are commonly used in heat exchangers and piping systems.

Material compatibility not only affects the longevity of the system but also impacts the thermal efficiency. Choosing the right materials is essential for ensuring reliable and long-lasting performance in challenging drilling environments.

System Scalability and Redundancy

Scalability is a critical factor in the design of a mud cooling system. The system should be able to accommodate different drilling depths and operational loads. Modular units allow operators to scale their cooling capacity as needed without major overhauls.

In addition to scalability, redundancy ensures that the mud cooling system continues to function even if one component fails. Redundant pumps, heat exchangers, and power supplies can be incorporated to enhance operational reliability.

Maintenance and Operational Efficiency

Routine Inspection and Cleaning

To maintain peak performance, regular inspection and cleaning of the mud cooling system are essential. This includes checking for scaling, blockages, and corrosion in the heat exchangers and piping.

Preventive maintenance reduces the risk of system failure and helps identify issues before they escalate. Implementing a scheduled maintenance plan extends the life of the system and ensures consistent cooling performance.

Energy Efficiency and Environmental Impact

Energy consumption is an important factor in the operation of a mud cooling system. Optimized flow rates, high-efficiency pumps, and smart control systems can reduce energy usage while maintaining effective cooling.

Minimizing environmental impact is also a priority. Using closed-loop systems helps reduce water usage and prevents contamination. Environmentally conscious designs not only meet regulatory requirements but also align with sustainable drilling practices.

Technological Innovations

Advanced Monitoring and Diagnostics

Modern mud cooling systems are equipped with advanced monitoring tools that provide real-time diagnostics. These tools help operators detect anomalies, predict maintenance needs, and optimize system settings for better performance.

Remote monitoring capabilities enable centralized oversight of multiple drilling sites, improving response times and reducing the need for on-site personnel. This level of automation enhances both safety and operational efficiency.

Integration with Digital Drilling Platforms

As digital transformation continues to reshape the drilling industry, integrating the mud cooling system with digital drilling platforms becomes increasingly beneficial. Data collected from sensors can be analyzed to optimize cooling strategies and improve decision-making.

Machine learning algorithms can also be employed to predict system behavior and recommend adjustments. This proactive approach ensures that the mud cooling system operates at peak efficiency under varying drilling conditions.

Frequently Asked Questions

What is the primary function of a mud cooling system?

The main purpose of a mud cooling system is to regulate the temperature of drilling mud in high-heat environments. This helps preserve the properties of the drilling fluid, protect downhole equipment, and ensure accurate measurement readings.

How does a heat exchanger work in a mud cooling system?

A heat exchanger reduces the temperature of the hot drilling mud by transferring its heat to a secondary cooling medium such as water or air. This process helps maintain the thermal stability of the drilling fluid as it recirculates.

Why is it important to monitor temperature in a mud cooling system?

Continuous temperature monitoring helps maintain optimal performance and prevent damage to equipment. By tracking temperature variations, operators can make timely adjustments to avoid overheating and ensure the longevity of the system.

Can a mud cooling system be customized for different drilling rigs?

Yes, many mud cooling systems are designed to be modular and scalable. This allows for customization based on rig size, power availability, and specific drilling conditions, ensuring compatibility and ease of deployment.

Table of Contents

- Understanding the Role of Mud Cooling Systems in Harsh Drilling Environments

- Core Structure of a Mud Cooling System

- Auxiliary Components That Enhance Performance

- Integration with Drilling Operations

- Design and Engineering Considerations

- Maintenance and Operational Efficiency

- Technological Innovations

- Frequently Asked Questions