Verständnis des Einflusses der Temperaturkontrolle von Bohrschlamm auf die Lebensdauer von Geräten

In der anspruchsvollen Welt der Bohroperationen ist die Aufrechterhaltung einer optimalen Leistung und Lebensdauer der Ausrüstung entscheidend für den operationellen Erfolg. Eine schlammerkältungssystem spielt dabei eine entscheidende Rolle, indem sie die Temperatur der Bohrflüssigkeit reguliert, wertvolle Ausrüstung schützt und einen reibungslosen Betrieb sicherstellt. Da sich Bohrtechnologien weiterentwickeln und die Operationen komplexer werden, wächst die Bedeutung eines effektiven Schlammtemperaturmanagements kontinuierlich.

Die Integration eines Schlammkühlsystems stellt eine strategische Investition dar, die weit über eine reine Temperaturregelung hinausgeht. Sie verändert grundlegend, wie Bohrausrüstung mit den rauen Bedingungen interagiert, die während des Betriebs auftreten, und schafft ein kontrollierteres und ausrüstungsfreundlicheres Umfeld. Dieser anspruchsvolle Ansatz im Wärmemanagement hat an Bedeutung gewonnen, da Bohrprojekte in immer schwierigere Gebiete und größere Tiefen vordringen.

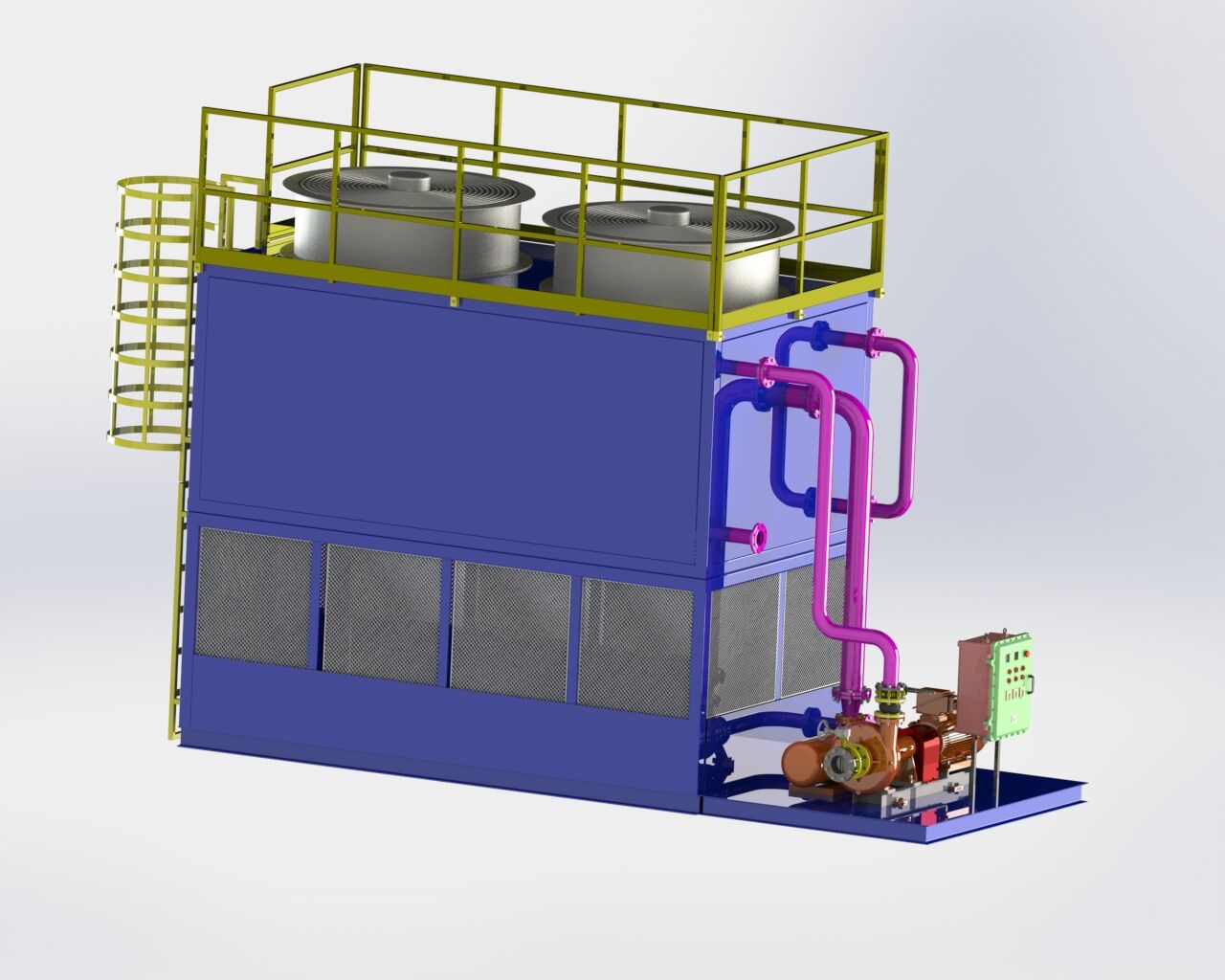

Kernkomponenten und Funktionalität von Schlammkühlsystemen

Wärmetauschertechnologie

Im Kern jedes Schlammkühlsystems steht die fortschrittliche Wärmetauschertechnologie. Diese spezialisierten Komponenten ermöglichen einen effizienten Wärmeübergang zwischen dem Bohrschlamm und dem Kältemittel, typischerweise Wasser oder einer speziellen Kühllösung. Die Konstruktion umfasst Hochleistungsmaterialien und optimierte Strömungsmuster, um die Kühlleistung zu maximieren und gleichzeitig die kritischen Eigenschaften des Bohrfluids beizubehalten.

Moderne Wärmetauscher in Schlammkühlsystemen verwenden Platten- oder Rohrbündelkonfigurationen, wobei jede je nach betrieblichem Kontext spezifische Vorteile bietet. Die Auswahl der geeigneten Wärmetauscherausführung hängt von Faktoren wie Schlammeigenschaften, Durchflussraten und geforderten Temperaturvorgaben ab.

Umwälz- und Regelmechanismen

Das Umlaufsystem gewährleistet eine korrekte Fluidbewegung durch den Kühlkreislauf, während gleichzeitig eine präzise Temperaturkontrolle aufrechterhalten wird. Fortschrittliche Pumpensysteme, kombiniert mit hochentwickelten Überwachungsgeräten, arbeiten harmonisch zusammen, um die Durchflussraten zu regulieren und die Kühlleistung zu optimieren. Diese sorgfältige Abstimmung der Komponenten hilft, Temperaturspitzen zu vermeiden, die Bohrausrüstung möglicherweise beschädigen könnten.

Moderne Steuerungssysteme verfügen über automatisierte Funktionen, die die Kühlparameter in Echtzeit anpassen, um auf Änderungen der Betriebsbedingungen zu reagieren und optimale Temperaturbereiche aufrechtzuerhalten. Dieses Maß an Regelpräzision hilft, Überkühlung oder unzureichende Kühlung zu verhindern, da beides die Leistung und Lebensdauer der Ausrüstung beeinträchtigen kann.

Direkte Vorteile für die Geräteleistung

Verringerung des mechanischen Verschleißes

Ein ordnungsgemäß implementiertes Schlammkühlsystem reduziert den mechanischen Verschleiß an Bohrausrüstungen erheblich. Durch die Aufrechterhaltung optimaler Betriebstemperaturen trägt das System dazu bei, thermische Belastungen für Komponenten wie Bohrköpfe, Motoren und Lager zu vermeiden. Diese Temperaturkontrolle führt direkt zu einer verlängerten Lebensdauer der Ausrüstung und geringeren Wartungsanforderungen.

Die Verringerung der Abnutzungsmuster ist besonders bei Hochlastkomponenten deutlich erkennbar, die regelmäßig extremen Bedingungen ausgesetzt sind. Das Kühlsystem schafft ein stabileres Betriebsumfeld, wodurch diese Komponenten länger innerhalb ihrer vorgesehenen Parameter arbeiten können.

Verbesserte Schmiereigenschaften

Die Temperaturkontrolle durch ein Schlammkühlsystem hilft dabei, die optimale Viskosität der Bohrflüssigkeiten aufrechtzuerhalten, um eine ordnungsgemäße Schmierung der Gerätekomponenten sicherzustellen. Wenn die Schlammtemperaturen richtig geregelt sind, bleiben die Schmiereigenschaften der Bohrflüssigkeit konstant, wodurch Reibung und Verschleiß an beweglichen Teilen reduziert werden.

Diese verbesserte Schmierwirkung ist besonders vorteilhaft für Bohrlochwerkzeuge und Bohrmotoren, bei denen die Aufrechterhaltung geeigneter Betriebsbedingungen entscheidend für die Lebensdauer der Ausrüstung ist. Das stabile Temperaturumfeld verhindert eine Verschlechterung der Schmiereigenschaften, die auftreten kann, wenn die Schlammtemperatur unkontrolliert ansteigt.

Langfristige wirtschaftliche Vorteile

Wartungskostensenkung

Die Implementierung eines Schlammkühlsystems führt langfristig zu erheblichen Reduzierungen der Wartungskosten. Durch die Vermeidung übermäßigen Verschleißes und thermischer Belastungen verlängert das System die Intervalle zwischen erforderlichen Wartungsarbeiten. Diese Verringerung der Wartungshäufigkeit führt direkt zu niedrigeren Betriebskosten und einer verbesserten Zuverlässigkeit der Ausrüstung.

Auch die Austauschzyklen der Ausrüstung werden verlängert, da Komponenten, die unter kontrollierten Temperaturbedingungen betrieben werden, ihre strukturelle Integrität und Leistungsmerkmale über längere Zeiträume hinweg beibehalten. Diese Verlängerung der Nutzungsdauer stellt eine erhebliche Rendite auf die Investition für die Bohroperationen dar.

Steigerung der Betriebswirtschaftlichkeit

Neben den direkten Wartungsvorteilen tragen Schlammkühlsysteme zur gesamten Betriebseffizienz bei. Temperaturbedingte Störungen werden minimiert, was zu einer konsistenteren Bohrleistung und weniger Ausfallzeiten führt. Die Fähigkeit des Systems, optimale Betriebsbedingungen aufrechtzuerhalten, hilft sicherzustellen, dass die Ausrüstung während ihrer gesamten Nutzungsdauer mit maximaler Effizienz arbeitet.

Diese Effizienzsteigerungen wirken sich auf den gesamten Bohrbetrieb aus, da ein stabiles Anlagenverhalten zu vorhersehbareren Abläufen und einer besseren Ressourcennutzung führt. Die dadurch erzielte Verbesserung der Betriebssicherheit trägt dazu bei, die Rendite der Investition in Bohrausrüstung zu maximieren.

Umwelt- und Sicherheitsaspekte

Vorteile des Thermomanagements

Ein effektives Wärmemanagement durch Schlammkühlsysteme trägt zu einer sichereren Arbeitsumgebung bei. Durch die Verhinderung einer übermäßigen Erwärmung reduzieren diese Systeme das Risiko von gerätebedingten Vorfällen und schützen das Personal vor Hochtemperaturbelastungen. Dieser Aspekt der Temperaturregelung ist besonders wichtig in anspruchsvollen Bohrumgebungen, in denen die Wärmeabfuhr entscheidend ist.

Die Fähigkeit des Systems, stabile Betriebstemperaturen aufrechtzuerhalten, hilft auch, thermische Belastungen an umliegender Ausrüstung und Infrastruktur zu verhindern, was zur allgemeinen Standortsicherheit und zum Umweltschutz beiträgt. Dieser umfassende Ansatz des Wärmemanagements entspricht den modernen Sicherheits- und Umweltstandards.

Nachhaltige Operationen

Moderne Schlammkühlsysteme verfügen über energieeffiziente Konstruktionen, die nachhaltige Bohrverfahren unterstützen. Durch die Optimierung der Kühlleistung und die Verringerung des Energieverbrauchs tragen diese Systeme dazu bei, die Umweltauswirkungen von Bohraktivitäten zu minimieren, während gleichzeitig eine effektive Temperaturkontrolle gewährleistet bleibt.

Der Fokus auf Nachhaltigkeit erstreckt sich auf die Rolle des Systems bei der Verhinderung von Geräteverschleiß, was indirekt die umweltschädlichen Auswirkungen reduziert, die mit dem Austausch und der Entsorgung von Ausrüstung verbunden sind. Diese Berücksichtigung ökologischer Aspekte stellt einen wichtigen Bestandteil moderner Bohroperationen dar.

Häufig gestellte Fragen

Welchen Temperaturbereich sollte ein Schlammkühlsystem zur optimalen Geräteschutz sicherstellen?

Der ideale Temperaturbereich liegt typischerweise zwischen 120 °F und 140 °F (49 °C bis 60 °C), kann jedoch je nach Gerätespezifikationen und Betriebsbedingungen variieren. Die Einhaltung dieses Temperaturbereichs trägt zur Optimierung der Geräteleistung bei und verhindert thermische Beanspruchung und Verschleiß.

Wie oft sollten die Komponenten des Schlammkühlsystems überprüft werden?

Regelmäßige Inspektionen sollten mindestens monatlich durchgeführt werden, bei intensiven Operationen häufiger. Wichtige Komponenten wie Wärmetauscher und Umlaufsysteme sollten vierteljährlich einer gründlichen Prüfung unterzogen werden, um eine optimale Leistung sicherzustellen und mögliche Probleme zu vermeiden.

Welche Faktoren beeinflussen die Dimensionierung eines Schlammkühlsystems?

Die Systemdimensionierung hängt von mehreren Faktoren ab, darunter die erwartete Wärmelast, die Schlammfördermengen, die Umgebungsbedingungen und die spezifischen Anforderungen der Ausrüstung. Weitere Aspekte sind die Bohrtiefe, Formationstemperaturen sowie die thermischen Eigenschaften des verwendeten Bohrfluids.