Viktige elementer i avanserte systemer for kontroll av boremuddets temperatur

Å opprettholde optimal temperatur i boringvæske er avgjørende for vellykkede boreoperasjoner, og et effektivt system for kjøling av leire har en viktig rolle i denne prosessen. Moderne boreprosjekter krever nøyaktig temperaturregulering for å sikre utstyrets levetid, bevare riktige væskeegenskaper og optimalisere den totale boreytelsen. Å forstå de viktigste komponentene i et system for kjøling av leire er essensielt for boreteknikere og driftsledere som ønsker å maksimere effektiviteten samtidig som de minimerer driftsrisiko.

Et godt designet slimkjølesystem representerer en betydelig investering i boreoperasjoner, men fordelene veier langt mer enn de første kostnadene. Fra å forhindre skader på utstyr til å sikre konsekvente slimeegenskaper, er disse systemene grunnleggende for vellykkede boreprosjekter i ulike miljøer og dyp.

Primære kjølesystemkomponenter

Varmvekslere og kjøletårn

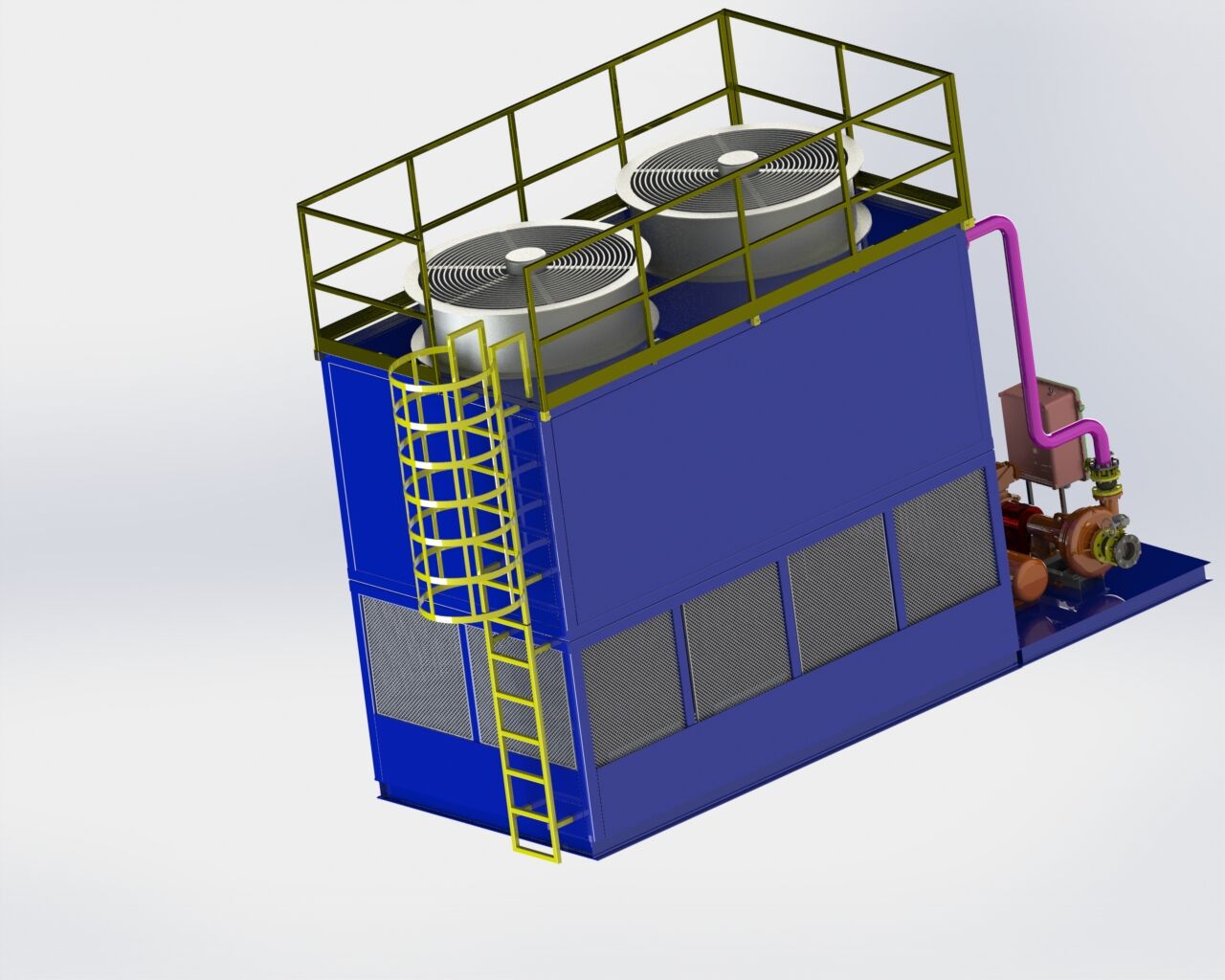

I hjertet av ethvert mudderkjølesystem ligger varmevekslersystemet. Disse spesialiserte enhetene gjør det mulig å overføre varme fra borevæsken til et kjølemedium, vanligvis vann eller luft. Moderne varmevekslere bruker plater eller shell-and-tube-konstruksjoner, og gir overlegen termisk effektivitet og pålitelig ytelse under krevende forhold.

Kjøletårn fungerer sammen med varmevekslere for å avlede den oppsamlede varmen ut i atmosfæren. Disse strukturene bruker prinsippet om fordampningskjøling, der varmt vann utsettes for bevegelig luft, noe som resulterer i temperaturreduksjon gjennom naturlig fordampning. Størrelsen og kapasiteten til kjøletårn må beregnes nøye basert på forventet varmelast og omgivelsesforhold.

Sirkulasjon og pumpeanlegg

Sirkulasjonssystemet består av høytytende pumper, rørnett og reguleringsventiler som sikrer korrekt væskestrøm gjennom hele mudderkjølingssystemet. Disse komponentene må være korrosjonsbestandige og i stand til å håndtere den erosive naturen til borevæsker, samtidig som de opprettholder konstante strømnivåer under varierende trykkforhold.

Avanserte pumpeanlegg inneholder ofte variabel frekvensstyring (VFD) for å optimere energiforbruket og gi nøyaktig strømkontroll. Denne teknologien gjør det mulig for operatører å justere kjøleytelsen basert på sanntids temperaturkrav og driftsbehov.

Temperaturövervåking og kontrollsystemer

Sensorer og måleinstrumenter

Nøyaktig temperaturmåling er avgjørende for å opprettholde optimal ytelse ved mudderavkjøling. Moderne oppsett bruker flere temperatursensorer plassert strategisk gjennom hele systemet for å gi sanntidsdata om væske temperaturene på ulike punkter. Disse sensorene må være robuste nok til å tåle det harde boremiljøet samtidig som de beholder nøyaktighet og pålitelighet.

Avanserte overvåkingssystemer inkluderer også strømningsmålere, trykksensorer og viskositetsmåleinstrumenter for å sikre omfattende kontroll over egenskapene til borvæsken. Disse dataene hjelper operatører med å ta informerte beslutninger angående justeringer av kjølesystemet og vedlikeholdsbehov.

Automatiske styresystem

Moderne mudderavkjølingsoppsett inneholder sofistikerte automatiserte kontrollsystemer som styrer alle aspekter av kjøleprosessen. Disse systemene bruker programmerbare logikkstyringer (PLC) og avanserte algoritmer for å opprettholde måltemperaturer samtidig som de optimaliserer energieffektiviteten.

Styresystemet kommuniserer med ulike komponenter, inkludert pumpehastigheter, ventilstillinger og kjøletårnsventilatorer, for å oppnå optimal ytelse. Muligheten til sanntidsdatalogging og trendanalyse hjelper operatører med å identifisere potensielle problemer før de blir kritiske.

Komponenter i sekundærkjølesystem

Filtrerings- og behandlingssystemer

Effektiv filtrering er avgjørende for å opprettholde effektiviteten i enhver muddkjøleoppsett. Disse systemene fjerner søppel, borrestøv og andre forurensninger som kan redusere varmeoverføringseffektiviteten eller skade systemkomponenter. Flere filtreringsstasjoner, inkludert syklonseparatorer og fintmaskede skjermer, sikrer omfattende partikkelavskillelse.

Vannbehandlingsystemer er like viktige, spesielt for kjøletårn, for å hindre avleiring og biologisk vekst. Kjemiske behandlingsprogram må nøye overvåkes for å opprettholde systemets effektivitet samtidig som man overholder miljøregulativene.

Nød- og reservesystemer

Pålitelige reservesystemer er avgjørende for å opprettholde kontinuerlig drift i tilfelle svikt i hovedsystemet. Dette inkluderer redundante pumper, reservestrømforsyning og nødkjølekapasitet. Regelmessig testing og vedlikehold av disse reservesystemene sikrer at de fungerer når de trengs.

Nødavstengningsprotokoller og omgåingssystemer gir ytterligere sikkerhetstiltak som beskytter både utstyr og personell i tilfelle systemfeil eller ekstreme forhold.

Systemintegrasjon og optimalisering

Ytelsesovervåkning og effektivitetsmål

Kontinuerlig ytelsesovervåkning bidrar til å opprettholde optimal effektivitet i mudderkjøleanlegget. Nøkkelytelsesindikatorer (KPI-er) som kjølekapasitet, energiforbruk og trykktap i systemet overvåkes og analyseres regelmessig for å identifisere forbedringsmuligheter.

Avanserte overvåkingssystemer kan generere detaljerte rapporter og trender, noe som muliggjør proaktiv vedlikeholdsplanlegging og systemoptimalisering. Denne datadrevne tilnærmingen bidrar til å minimere driftskostnader samtidig som påliteligheten til kjølesystemet maksimeres.

Vedlikehold og oppgradering

Regelmessig vedlikehold er avgjørende for å sikre langtidspålitelighet for mudderkjøleanlegget. Dette inkluderer planlagte inspeksjoner, rengjøring av varmevekslere, kalibrering av sensorer og utskifting av slitasjedeler. Et omfattende vedlikeholdsprogram hjelper til med å forhindre uventet nedetid og forlenge utstyrets levetid.

Systemoppgraderinger bør vurderes periodisk for å integrere nye teknologier og forbedre effektiviteten. Dette kan inkludere innføring av variabel hastighetsstyring, oppgradering av kontrollsystemer eller implementering av mer effektive varmevekslerdesign.

Ofte stilte spørsmål

Hvor ofte bør et mudderkjøleanlegg serviceeres?

En omfattende serviceplan bør inkludere daglige visuelle inspeksjoner, ukentlige ytelseskontroller og månedlig detaljert vedlikehold. Store systemrevisjoner anbefales vanligvis årlig, selv om dette kan variere avhengig av driftsforhold og bruksintensitet.

Hva er tegn på et ineffektivt mudderkjølesystem?

Nøkkelen til indikatorer inkluderer ustabil temperaturregulering, økt energiforbruk, uvanlig støy eller vibrasjoner, reduserte strømningshastigheter og hyppige systemalarmer. Regelmessig overvåkning av disse parameterne hjelper med å identifisere potensielle problemer før de fører til systemfeil.

Hvordan kan effektiviteten i mudderkjøleanlegg forbedres?

Effektivitetsforbedringer kan oppnås gjennom regelmessig vedlikehold, oppgradering til mer effektive komponenter, optimalisering av kontrollsystemer, sikring av riktig isolasjon og innføring av energigjenvinningssystemer. Regelmessig analyse av ytelsesdata hjelper med å identifisere spesifikke områder for forbedring.

Hvilke miljøfaktorer påvirker ytelsen til mudderkjøling?

Omgivende temperatur, fuktighet, høyde over havet og luftkvalitet påvirker alle ytelsen til kjølesystemer. Disse faktorene må tas hensyn til under systemdesign og drift for å sikre optimal ytelse under ulike miljøforhold.