Məhsul Təsviri

MD316-nın işləmə prensipi Qurğan temizləyici qum pomzası vasitəsilə çamırı müəyyən basinq və sürətlə döyüşçünin icki divarına sönümürək. Mərkəzi forqlaşdırma və引力əsasında, böyük qab qırqır döyüşçünin icki divarını boyuca spiral şəkildə çəkilsin, alt axın portundan çıxarılıb və aşağıda olan mikro şəbəkəli rəqsləndiriciyə düşür; əks tərəfdən ortam döyüşçünün üzərinə spiral şəkildə yuvarlanır və nəticə olaraq köpük portundan sıxışdırılır və növbəti rəqsləndiriciyə keçid edilir.

|

|

Növ Parametr

Model nömrəsi |

MD216, MD316, MD320 |

Rəqs növü |

آلبوم |

Motor Növü |

Qısa Motor |

Güç (kW) / (hp) |

1.72 kW×2 |

Rəqs güclüyu (G-Force) |

6.5~7.2G ayarlamaq olar |

Ümumi şəbəkə sahəsi (㎡) / (ft2) |

2.7㎡ |

Ekranın burxu ayarlanma diapazonu (°) |

-1°~5° |

İşlem kapasitesi (m3/sa) \/(GPM) |

240~320m³/sa |

Ekran növü |

Düz ekran |

Ekran ölçüsü - Miqdarı (mm)\/(inc) |

585×1165-4 |

Desander siklon spesifikasiyları |

250/10〞,300/12〞 |

Qum çıxarış çilondanın sayını |

2~3 |

Qum çilondanın ayırma ölçüsü (μm) |

44~74μm |

Çamur çilondanın xüsusiyyətləri |

100/4〞 |

Çamur çilondanın sayını |

16~20 |

Çamur çilondanın ayırma ölçüsü (μm) |

14~47μm |

Şöngü (Db) |

<85 |

Ölçü L*W*H (mm) \/(inc) |

3280×2180×3075 |

Çəki (kg) / (funtda) |

3450 |

Rəqabət Üstünlüyü

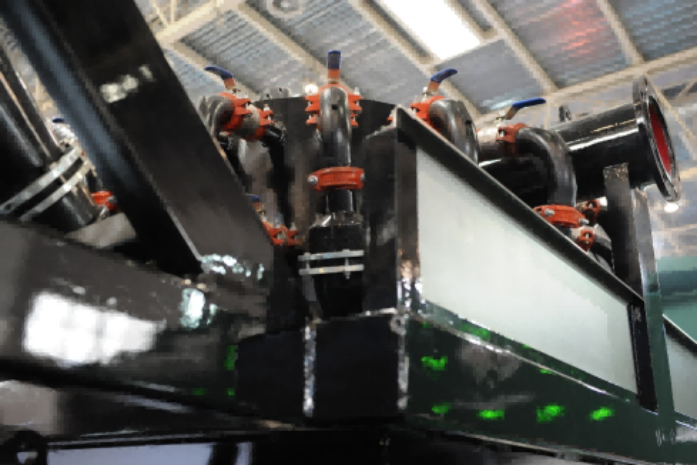

● Unikal round desilter quruluş dizaynı, çıxarılabilir qalmaz çelik perde, akış göstəricisi ilə donanmışdır

● 10-inc desander və 4-inc desander standart konfigurasiyalardır, hər ikisi də segmentlərə bölünür və əvəz edilir strukturlardır

● Hamısı fərdi kürpəli vəlvə ilə donanmışdır, üztəsiz idarə edilir və əvəz olunur

● Silon poliüretan dan ibarətdir

Tətbiq sahələri

● Neft sondajı çamırının işlənmesi

● Trenchless inqinerinq çamırı işləməsi

● Şild inşaati zamanı çamır və su ayırmaları

Applicatio n Black Rhino Məhsullarının Ssenariləri

Quruducu maye təmizləmə sistemləri

Kəsici emalı və bərpa

Tullantı neft və çamurun su təmizlənməsi

Quruducu tullantıların minimuma endirilməsi və təkrar emalı

Yandırma və mineral emalı tullantılarının arıtılması

Qum və qırıntı yuyucu təchizatının təkrar istifadəsi

Kimyəvi və dərman preparatlarının qatılaşdırılması

Neftin və petrokimyəvi zavodlarda neft-su ayrılması

Soyutma və emal mayelərinin təkrar emalı

Emulsiyanın parçalanması və karbohidrogenlərin giderilməsi

CBM kəşfiyyatı və istehsalında bərk maddələrin idarə edilməsi

Qazma tullantılarının idarə edilməsi və mayelərin təkrar emalı

Qapalı dövrəli qazma təmizləyici sistemlər

Kərbəz quraşdırılması üçün gil qarışıqlarının təkrar emal sistemi

Suspensiyaların ayrılması və bentonitin bərpası

Şəhər keçidləri və çay keçidləri üçün qazma dəstəyi

TBM qalxanlarında torpaq şərtləndirilməsi və suspenziya təmizlənməsi

Qazıntıların və əlavələrin ayrılması və təkrar emalı

Tunel qurğusunun idarə edilməsi və suyun təkrar istifadəsi

SSS

S: Əsasən hansı növ avadanlıqlar istehsal edirsiniz?

C: Black Rhino neft və qaz sənayesi və transşəhər qazma sahəsində yüksək keyfiyyətli avadanlıqların istehsalına yönəlmişdir. Əsas məhsulları isə neft qazmaları, istiqamətlənmiş keçidlər və ətraf mühitin mühafizəsi kimi mühəndislik sahələrində geniş tətbiq olunan bərkidici sistemlər, qarışdırıcı qurğular, qazma tullantılarının emalı üçün avadanlıqlar, sentrifujlar və s. daxildir.

S: Sifariş olunmuş tələblər üçün avadanlıqlarınız uyğundurmu?

B: Bəli, müştərilərin konkret texniki tələblərinə və obyektdə mövcud şərtlərə əsasən avadanlıq ölçüsünün, funksiyalarının və konfiqurasiyalarının elastik şəkildə tənzimlənməsini təmin edə bilərik, mövcud avadanlıqlarla və ya avtomobillərlə mükəmməl uyğunluq və müxtəlif bölgələrin və layihələrin müxtəlif tələblərini ödəməsini təmin edə bilərik.

S: Məhsullarınız beynəlxalq standartlar və sertifikatlarla uyğun gəlirmi?

B: Biz ISO 9001 keyfiyyət idarəetmə sistemi sertifikatından keçmişik. Bəzi məhsullarımızın Beynəlxalq sertifikatları (CE və API) mövcuddur. Biz avadanlığın iş performansı, təhlükəsizlik və ətraf mühitin qorunması baxımından beynəlxalq bazar tələblərinə cavab verdiyini təmin etmək üçün sərt şəkildə sənaye standartlarına əməl edirik.

S: Qlobal satışdan sonrakı xidmət və texniki dəstəyi təmin edə bilərsinizmi?

B: Bəli, biz hər yerdə xidmət mərkəzlərinə malikik, 24 ay müddətinə hesablanan məhsul keyfiyyəti zəmanəti, həmçinin müştərilərin avadanlıqlarının sabit işləməsini təmin etmək və bütün növ texniki tələblərə operativ cavab vermək üçün ömür boyu texniki dəstək və satışdan sonrakı məsləhət xidməti təklif edirik.

S: Siz xarici layihələrdə əməkdaşlıq təcrübəsinə maliksinizmi?

B: Məhsullarımız Avropa, Amerika, Yaxın Şərq, Cənubi-Şərqi Asiya, Okeaniya və s. kimi 70-dən çox ölkəyə ixrac edilib. Bir çox beynəlxalq energetika və mühəndislik müəssisələri ilə uzunmüddətli əməkdaşlıq münasibətləri qurmuşdur və xarici layihələrin təhvil verilməsi və xidməti sahəsində zəngin təcrübəyə malikdir.