Product Description

Black rhino D355 Decanter Centrifuge is used for sedimentation and separation of suspension with solid particle diameter 2μm, the barite recovery rate can reach more than 90%, and the specific gravity and viscosity of the treated mud can meet the ideal operation requirements, providing conditions for better recycling and high efficiency, energy saving and environmental protection.

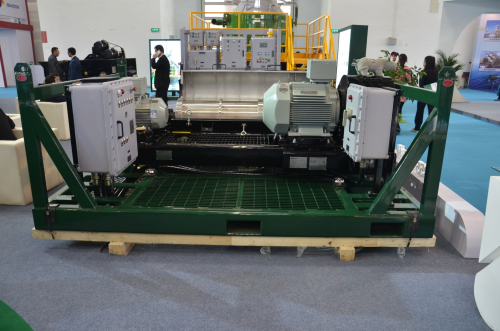

D355 centrifuge is mainly composed of collection box, main and auxiliary motor cover, base, differential, hydraulic coupling, transmission device, control system, bracket and so on. It is mainly applicable to the occasions where the mud density changes greatly, the working condition is complex, and the ideal treatment effect needs to be achieved by adjusting the operating parameters of the centrifuge, such as shale gas Wells and high temperature and pressure Wells.

Type Parameter

Model number |

DC355-Constant speed |

DC355-VFD |

Bowl Diameter(mm)/(in) |

355 |

355 |

Bowl Length(mm)/(in) |

1257 |

1257 |

Max. Bowl Speed(RPM) |

3900 |

3900 |

Typical Bow Speed(RPM) |

3200 |

~3200 |

Separation factor G-Force |

2033 |

~2033 |

Max Capacity(m³/h) |

35 |

35 |

D50 Separation point (μm) |

2~5 |

2~5 |

Main Motor(kW) Main motor (KW) |

30 |

30 |

Auxiliary Motor Power Back Drive Motor(kW) |

7.5 |

7.5 |

Dimension: L×W×H(mm)/(in) |

2830×1555×1760 |

2830×1555×1760 |

Weight Weight(KG) |

2305 |

2305 |

Electrical Power |

380V/50Hz 460V/60H |

380V/50Hz 460V/60H |

CompetitiveAdvantage

● Standard ergonomic and HSE compliant base frame design.

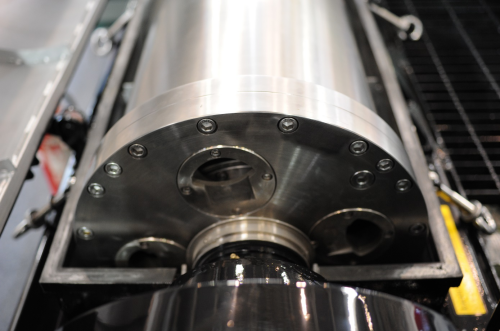

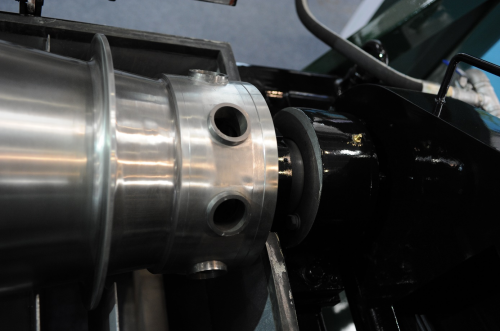

● 316 stainless steel material, the best aspect ratio design.

● Adjustable liquid phase outlet, cemented carbide nested solid phase outlet.

● Cemented carbide insert screw propeller, anti-corrosion wear, easy to maintain.

● The motor base can be adjusted bidirectional in X and Y axis, and the centrifuge speed can be adjusted (fixed-speed centrifuge).

● Equipped with vibration sensor, perfect warning function.

● Positive pressure explosion-proof frequency conversion control cabinet, can be equipped with stainless steel body, PLC touch screen control

● Intelligent control, easy operation, large processing capacity, good effect, low failure rate.

Applications

After years of development, production, field application and continuous optimization and improvement, Black rhino D355 centrifuge has the advantages of good separation effect, large processing capacity, reliable operation, long life, low energy consumption, easy maintenance, smooth operation, low noise, and is widely used in chemical, petroleum, food, pharmaceutical, environmental protection and other fields.

Application Scenarios of Black Rhino Products

Drilling fluid purification systems

Cutting treatment and recovery

Waste mud and sludge dewatering

Drilling waste minimization and recycling

Mining and mineral processing tailings treatment

Sand and aggregate washing wastewater recycling

Chemical and pharmaceutical slurry dewatering

Oil-water separation in refinery and petrochemical plants

Coolant and machining fluid recycling

Emulsion breaking and hydrocarbon removal

Solids control in CBM exploration and production

Drilling waste management and fluid recycling

Closed-loop drilling cleaning systems

Mud recycling systems for pipeline installation

Slurry separation and bentonite recovery

Urban crossing and river crossing drilling support

Soil conditioning and slurry treatment in TBM shields

Separation and recycling of muck and additives

Tunnel spoil management and water reuse

FAQ

Q: What types of equipment do you mainly produce?

A:Black Rhino focuses on the manufacturing of high-end equipment in the oil and gas and trenchless drilling fields. Its main products include solid control systems, slurry mixing devices, drilling waste treatment equipment, centrifuges, etc., which are widely used in engineering scenarios such as oil drilling, directional crossing, and environmental protection.

Q: Does your equipment support customized requirements?

A: Yes, we can provide flexible customization of equipment size, functions and configurations based on the on-site conditions and specific technical requirements of customers, ensuring a perfect match with existing equipment or vehicles and meeting the diverse needs of different regions and projects.

Q: Does your products comply with international standards and certifications?

A: We has passed the ISO 9001 quality management system certification. Some of its products have international certifications such as CE and API. It strictly follows industry standards to ensure that the equipment meets international market demands in terms of performance, safety and environmental protection.

Q: Can you provide global after-sales service and technical support?

A: Yes, we have service outlets in many regions around the world, offering a 24-month product quality guarantee as well as lifetime technical support and after-sales consultation services to ensure the stable operation of customers' equipment and respond promptly to all kinds of technical demands.

Q: Do you have any experience in overseas project cooperation?

A:Our products have been exported to over 70 countries and regions in Europe, America, the Middle East, Southeast Asia, Oceania and so on. It has established long-term cooperative relationships with many international energy and engineering enterprises and has rich experience in overseas project delivery and service.