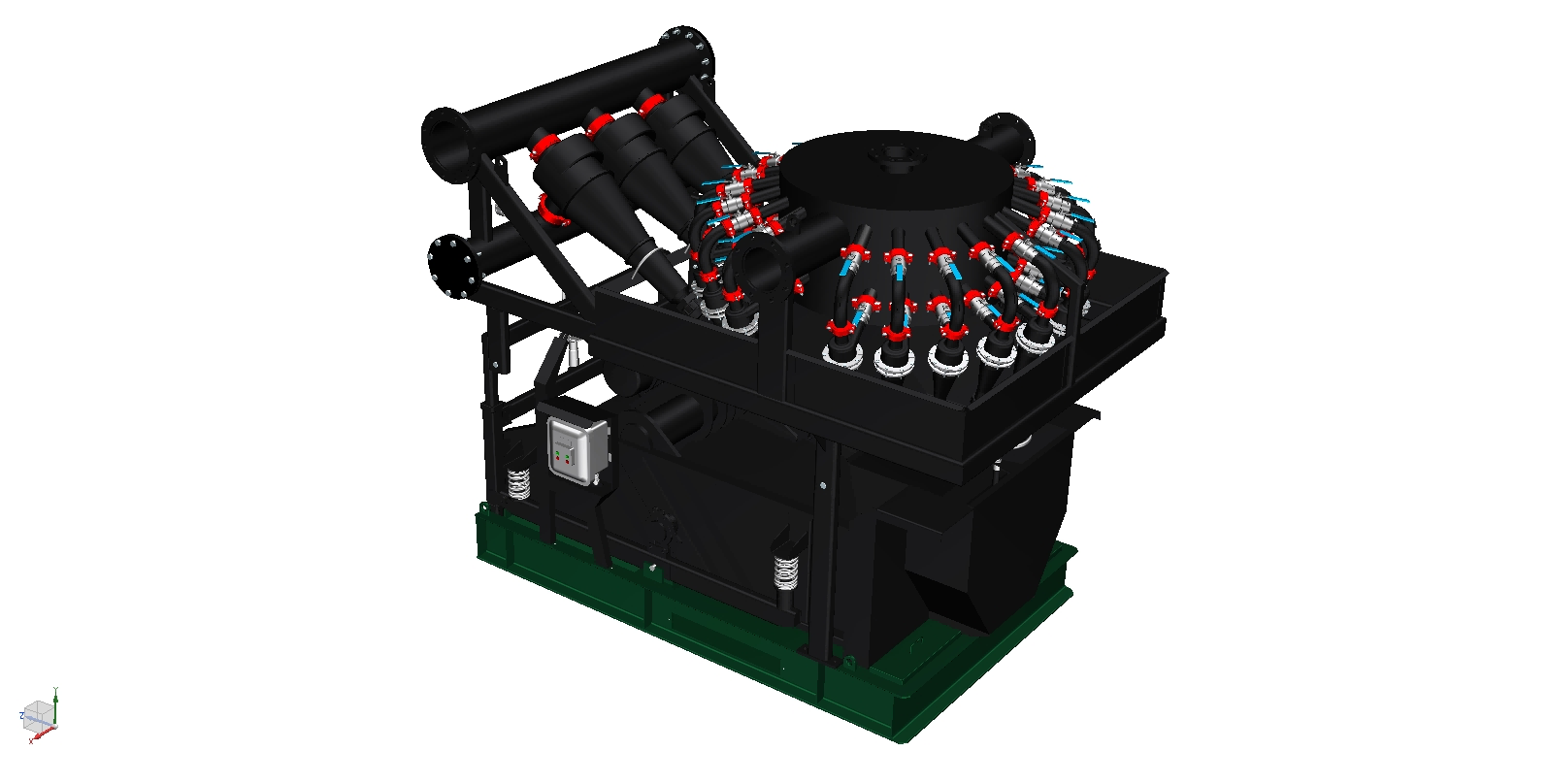

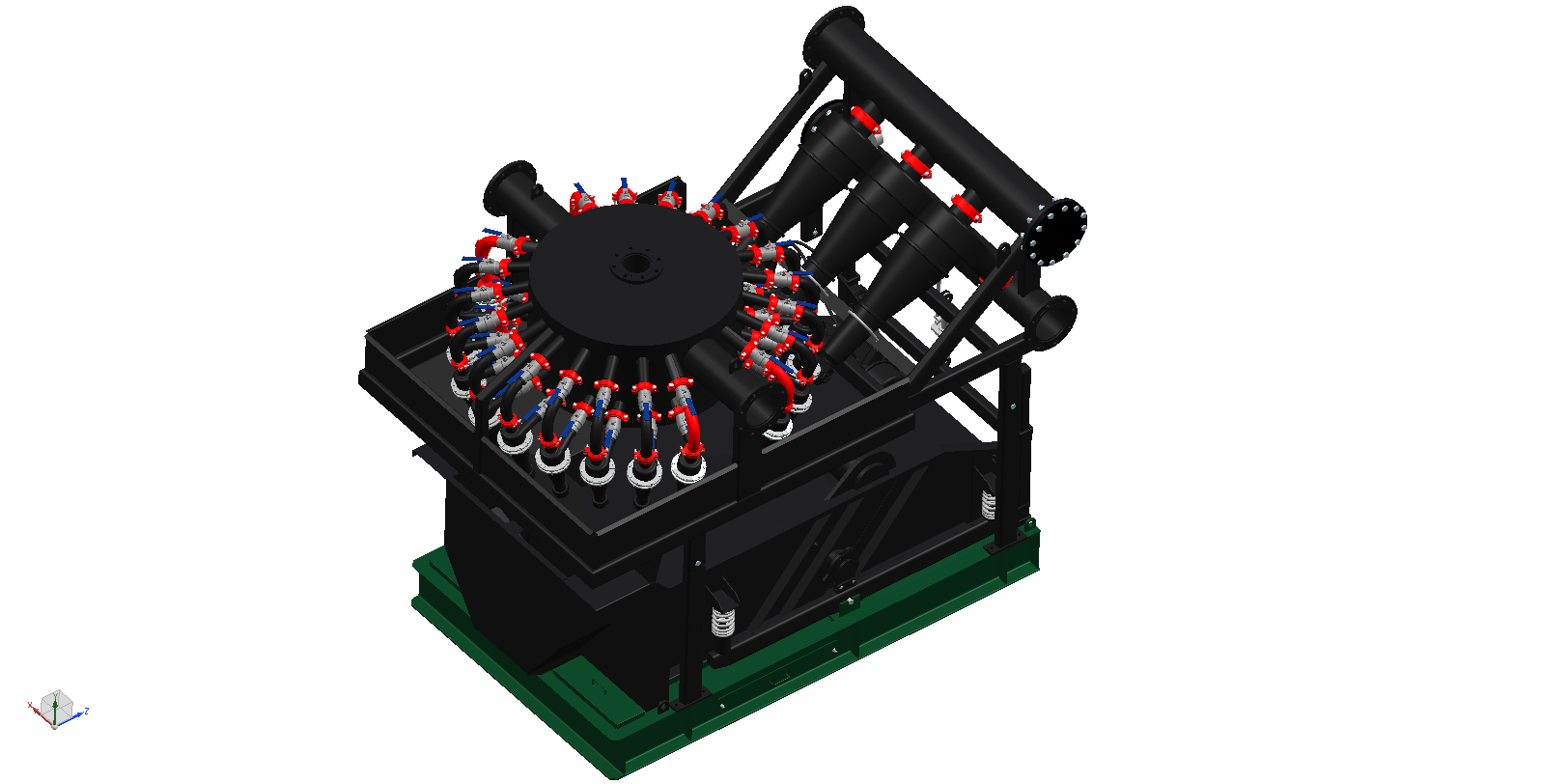

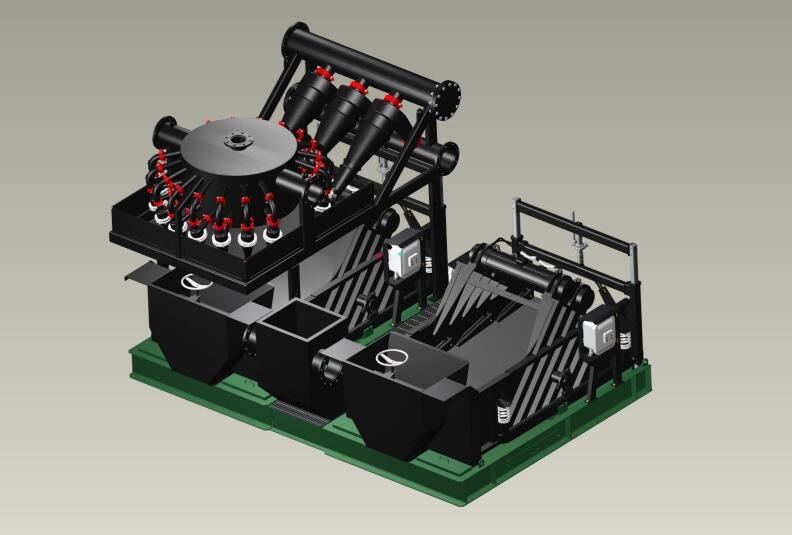

Product Description

Mud cleaner is also called Desander and Desilter, is the sand cyclone and mud removal cyclone and bottom flow mud vibrating screen combined three to one, processing the small particles contained in the mud solid phase separation, black rhino MD series mud cleaner is used to remove solid phase particles in drilling fluid equipment, to ensure the stability of drilling fluid performance, improve drilling efficiency, ensure drilling safety.

Type Parameter

Model number |

MD216、MD316、MD320 |

Mode of vibration |

Linear |

Motor type |

Short motor |

Power (kW) /(hp) |

1.72 kW×2 |

Vibration strength (G-Force) |

6.5~7.2G adjustable |

Total screen area (㎡) /(ft2) |

2.7㎡ |

Screen Angle adjustment range (°) |

-1°~5° |

Processing capacity (m3/h) /(GPM) |

240~320m³/h |

Screen type |

Flat screen |

Screen size - Quantity (mm)/(in) |

585×1165-4 |

Desander cyclone specifications |

250/10〞,300/12〞 |

Number of sand removal cyclones |

2~3 |

Sand cyclone separation size (μm) |

44~74μm |

Desilting cyclone specifications |

100/4〞 |

Number of desilting cyclone |

16~20 |

Desilting cyclone separation size (μm) |

14~47μm |

Noise (dB) |

<85 |

Size L*W*H (mm) /(in) |

3280×2180×3075 |

Weight (kg) /(lbs) |

3450 |

Competitive Advantage

● Unique round desilter assembly design, removable stainless steel baffle, equipped with flow meter

● 10-inch desander and 4-inch desander are standard configurations, both of which are segmented removable and replaceable structures

● All equipped with individual ball valve control, easy maintenance and replacement

● The cyclone is made of polyurethane

Applications

● Oil drilling: used to deal with a large number of mud produced in the process of oil drilling, remove the rock debris, sand and other solid particles, so that the mud can be recycled and reduce costs.

● Trenchless engineering: In the trenchless construction of urban underground pipeline laying and tunnel digging, the mud can be purified to realize the recycling of mud and reduce the pollution to the environment.

● Shield construction: In the process of tunneling, the mud generated needs to be effectively treated and purified, and the mud cleaner can help remove impurities in the mud and maintain the stability of the mud performance.

Application Scenarios of Black Rhino Products

Drilling fluid purification systems

Cutting treatment and recovery

Waste mud and sludge dewatering

Drilling waste minimization and recycling

Mining and mineral processing tailings treatment

Sand and aggregate washing wastewater recycling

Chemical and pharmaceutical slurry dewatering

Oil-water separation in refinery and petrochemical plants

Coolant and machining fluid recycling

Emulsion breaking and hydrocarbon removal

Solids control in CBM exploration and production

Drilling waste management and fluid recycling

Closed-loop drilling cleaning systems

Mud recycling systems for pipeline installation

Slurry separation and bentonite recovery

Urban crossing and river crossing drilling support

Soil conditioning and slurry treatment in TBM shields

Separation and recycling of muck and additives

Tunnel spoil management and water reuse

FAQ

Q: What types of equipment do you mainly produce?

A:Black Rhino focuses on the manufacturing of high-end equipment in the oil and gas and trenchless drilling fields. Its main products include solid control systems, slurry mixing devices, drilling waste treatment equipment, centrifuges, etc., which are widely used in engineering scenarios such as oil drilling, directional crossing, and environmental protection.

Q: Does your equipment support customized requirements?

A: Yes, we can provide flexible customization of equipment size, functions and configurations based on the on-site conditions and specific technical requirements of customers, ensuring a perfect match with existing equipment or vehicles and meeting the diverse needs of different regions and projects.

Q: Does your products comply with international standards and certifications?

A: We has passed the ISO 9001 quality management system certification. Some of its products have international certifications such as CE and API. It strictly follows industry standards to ensure that the equipment meets international market demands in terms of performance, safety and environmental protection.

Q: Can you provide global after-sales service and technical support?

A: Yes, we have service outlets in many regions around the world, offering a 24-month product quality guarantee as well as lifetime technical support and after-sales consultation services to ensure the stable operation of customers' equipment and respond promptly to all kinds of technical demands.

Q: Do you have any experience in overseas project cooperation?

A:Our products have been exported to over 70 countries and regions in Europe, America, the Middle East, Southeast Asia, Oceania and so on. It has established long-term cooperative relationships with many international energy and engineering enterprises and has rich experience in overseas project delivery and service.