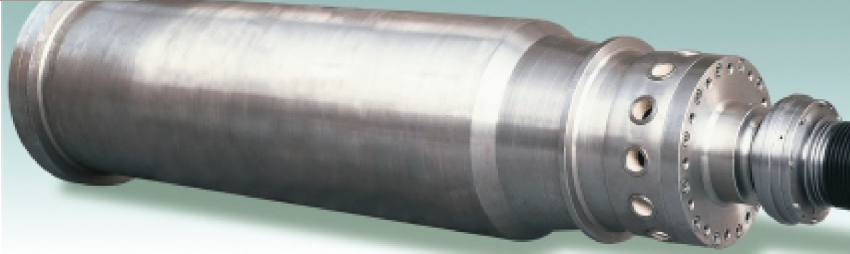

The rotating drum is made of duplex stainless steel integral centrifugal casting, and the inlet and outlet uses special wear-resistant materials. The strength and rigidity are far higher than ordinary stainless steel, with less vibration, better corrosion resistance, better wear resistance and longer service life

Description:

●The rotating drum is made of duplex stainless steel integral centrifugal casting, and the inlet and outlet uses special wear-resistant materials. The strength and rigidity arefarhigher than ordinary stainless steel, with less vibration, better corrosion resistance, better wear resistance and longer service life;

●The structure of large aspect ratio is adopted, which lengthens the sedimentation area, prolongs the separation time, and has larger processing capacity and better effect;

●The spiral structure design is pertinent, which not only ensures the dryness of the mud but also makes the slag discharge smooth;

●unique in volute planetary gear differential with large transmission ratio, differential speed and torque can be flexibly adjusted;

●Special steel frame with strong bearing capacity and no deformation to ensure stable operation of the equipment.

●The wear-resistant parts of the spiral blade are made of special wear resistant alloy materials to ensure abrasion resistance and no rupture.

The rotating drum is made of duplex stainless steel by centrifugal casting. The rigidity and strength are greatly improved, vibration is reduced, and noise is reduced. The slag outlet is inlaid with ceramic sleeves or cemented carbide sleeves to improve wear resistance and corrosion resistance.

|

|

Technicalindexes:

Feeding concentration range:0.5%-35%

Solid recovery rate: -99%

Processing capacity: 0.3-88m3/h

Mud cake moisture content (urban sludge): 75%

Noise: < 85d B(A)

Length to diameter ratio: 2.42-5.1

Separation factor: 630-4000; (up to 4200)

Supportingequipment:

|

|

| Thin oil station | Distribution cabinet |

Model and technical parameter

Type |

Length of rotary drum (mm) |

Rotary speed of rotary drum (rpm) |

Separator factor |

motor power(kw) |

Production capacity (m3/h) |

Dimension and size (mm) |

Weight(kg) |

differential |

LW320 |

1350 |

Max4720 |

4000 |

15&5.5 |

4-8 |

2950x790x1270 |

2010 |

Planetary gear |

LW355A |

1280 |

Max4500 |

4000 |

22&5.5 |

6-13 |

2980 X 820 X1300 |

2050 |

Planetary gear |

LW355B |

1490 |

Max4500 |

4000 |

22&7.5 |

8-20 |

3200 X 820 X 1300 |

2580 |

Planetary gear |

LW430A |

1800 |

Max4100 |

4000 |

30&11 |

12-33 |

3620x950x1400 |

4180 |

Planetary gear |

LW430B |

2190 |

Max4100 |

4000 |

37&15 |

13-38 |

4020x950x1400 |

4950 |

Planetary gear |

LW450A |

1890 |

Max4000 |

4000 |

37&11 |

15-40 |

3750x1260x1530 |

4460 |

Planetary gear |

LW450B |

2300 |

Max4000 |

4000 |

45&11 |

16-45 |

4140x1260x1530 |

4730 |

Planetary gear |

LW530A |

2230 |

Max3700 |

4000 |

55&15 |

20-51 |

3800x2000x1250 |

5500 |

Planetary gear |

LWS30B |

2230 |

Max3700 |

4000 |

75&15 |

20-52 |

4520x1530x1630 |

6070 |

Planetary gear |

LW560A |

2240 |

Max3500 |

3800 |

55&15 |

22-50 |

3800x2000x1250 |

5620 |

Planetary gear |

LW560B |

2240 |

Max3500 |

3800 |

75&15 |

22-55 |

4520x1530x1630 |

6280 |

Planetary gear |

LW620A |

1860 |

Max2750 |

2600 |

75&15 |

25-68 |

3700x2000x1400 |

5720 |

Planetary gear |

LW620B |

2170 |

Max2700 |

2500 |

75&15 |

30-70 |

4000 X 2000 X1400 |

6150 |

Planetary gear |

LW680A |

2040 |

Max2570 |

2500 |

75&18.S |

32-72 |

3800x2100x1530 |

6760 |

Planetary gear |

LW680B |

2180 |

Max2520 |

2400 |

75&22 |

35-76 |

4000x2100x1530 |

7210 |

Planetary gear |

LW750A |

2250 |

Max2350 |

2300 |

90&22 |

38-78 |

4150x2200x1570 |

7930 |

Planetary gear |

LW750B |

2400 |

Max2300 |

2200 |

90&30 |

40-81 |

4300x2200x1570 |

8140 |

Planetary gear |

LW820A |

2460 |

Max2200 |

2100 |

110&30 |

43-83 |

4500 X 2200 X1650 |

8760 |

Planetary gear |

LW820B |

2620 |

Max2000 |

2100 |

110&37 |

45-88 |

4700x2400x1650 |

9350 |

Planetary gear |

Applications:

The LWserieshorizontal screw sedimentation discharge centrifuge is a highly efficient and continuous solid-liquid separation equipment, widely used in multiple industrial fields. It mainly relies on centrifugal force to separate solid particles from liquids in suspensions. Its typical application fields include:

1.Environmental protection and sewage treatment

Municipal sewage treatment: Dewatering of sludge (such as activated sludge and biochemical sludge), reducing the moisture content to facilitate subsequent disposal.

Industrial wastewater treatment: It is applicable to the dewatering of high-concentration wastewater sludge in industries such as chemical engineering, printing and dyeing, paper making, and electroplating.

River dredging: Dehydrating and reducing the volume of silt to lower transportation and landfill costs.

2. Chemical Engineering and Petrochemical Engineering

Catalyst separation: Recover the solid catalyst after the reaction.

Polymer treatment: Dehydration of synthetic resins such as PVC and PE.

Oil sludge treatment: Separate the oily sludge produced during the process of oil extraction or refining, and recover the oil.

3. Food and Bioengineering

Starch processing: Dehydration and washing of corn and potato starch.

Fermentation liquid treatment: such as the separation of yeast and antibiotic cells.

Juice clarification: Remove solid impurities such as pulp fibers.

4. Minerals and Metallurgy

Tailings treatment: Dehydrate the tailings from mines to achieve dry stacking or resource recovery.

Metal concentrate dehydration: Concentration and separation of minerals such as copper, zinc and aluminum.

Coal chemical industry: Coal slime dewatering and coal tar residue treatment.

5. Pharmaceutical industry

Separation of medicinal residue: Dehydration of the medicinal residue after extraction from traditional Chinese medicine.

Biological preparations: Solid-liquid separation of cell culture media and fermentation products.

6. Papermaking industry

Pulp dewatering: Fiber recovery in the process of waste paper regeneration.

White mud treatment: Calcium carbonate separation during the alkali recovery process.

ApplicationScenariosofBlackRhinoProducts

Drilling fluid purification systems

Cutting treatment and recovery

Waste mud and sludge dewatering

Drilling waste minimization and recycling

Mining and mineral processing tailings treatment

Sand and aggregate washing wastewater recycling

Chemical and pharmaceutical slurry dewatering

Oil-water separation in refinery and petrochemical plants

Coolant and machining fluid recycling

Emulsion breaking and hydrocarbon removal

Solids control in CBM exploration and production

Drilling waste management and fluid recycling

Closed-loop drilling cleaning systems

Mud recycling systems for pipeline installation

Slurry separation and bentonite recovery

Urban crossing and river crossing drilling support

Soil conditioning and slurry treatment in TBM shields

Separation and recycling of muck and additives

Tunnel spoil management and water reuse

FAQ

Q: What types of equipment do you mainly produce?

A:Black Rhino focuses on the manufacturing of high-end equipment in the oil and gas and trenchless drilling fields. Its main products include solid control systems, slurry mixing devices, drilling waste treatment equipment, centrifuges, etc., which are widely used in engineering scenarios such as oil drilling, directional crossing, and environmental protection.

Q: Does your equipment support customized requirements?

A: Yes, we can provide flexible customization of equipment size, functions and configurations based on the on-site conditions and specific technical requirements of customers, ensuring a perfect match with existing equipment or vehicles and meeting the diverse needs of different regions and projects.

Q: Does your products comply with international standards and certifications?

A: We has passed the ISO 9001 quality management system certification. Some of its products have international certifications such as CE and API. It strictly follows industry standards to ensure that the equipment meets international market demands in terms of performance, safety and environmental protection.

Q: Can you provide global after-sales service and technical support?

A: Yes, we have service outlets in many regions around the world, offering a 24-month product quality guarantee as well as lifetime technical support and after-sales consultation services to ensure the stable operation of customers' equipment and respond promptly to all kinds of technical demands.

Q: Do you have any experience in overseas project cooperation?

A:Our products have been exported to over 70 countries and regions in Europe, America, the Middle East, Southeast Asia, Oceania and so on. It has established long-term cooperative relationships with many international energy and engineering enterprises and has rich experience in overseas project delivery and service.