တူးဖော်ရေးလုပ်ငန်းများတွင် အပူချိန်ထိန်းချုပ်မှု၏ သက်ရောက်မှုကို နားလည်ခြင်း

တူးဖော်ရေးလုပ်ငန်းများ၏ ထိရောက်မှုသည် အချက်များစွာအပေါ်တွင် မူတည်သော်လည်း ၎င်းတို့အနက် အရေးပါသော်လည်း မကြာခဏ လျစ်လျူရှုလေ့ရှိသည့် အချက်မှာ ရွှံ့ရည်အေးခဲခြင်းဖြစ်သည်။ တူးဖော်ရေးလုပ်ငန်းများသည် ပိုမိုရှုပ်ထွေးလာပြီး လိုအပ်ချက်များ ပိုမိုများပြားလာသည်နှင့်အမျှ အပူချိန်ထိန်းချုပ်မှုစနစ်များအတွက် လိုအပ်ချက်မှာ ယခင်ကမဟုတ်သလောက် အရေးပါလာခဲ့သည်။ ခေတ်မီတူးဖော်ရေးစီမံကိန်းများသည် တူးဖော်ရေးစွမ်းဆောင်ရည်၊ ကိရိယာသက်တမ်းနှင့် စုစုပေါင်းစီမံကိန်းကုန်ကျစရိတ်တို့ကို တိုက်ရိုက်သက်ရောက်မှုရှိသည့် အတွင်းပိုင်းအပူချိန်များကို စီမံခန့်ခွဲရာတွင် မတွေ့ကြုံဖူးသည့် စိန်ခေါ်မှုများကို ရင်ဆိုင်နေရသည်။

အဆင့်မြင့် မြေစေးအေးခဲခြင်းနည်းပညာများ သွင်းတူးရာတွင် အပူချိန်ကို သင့်တော်သောအဆင့်တွင် ထိန်းသိမ်းပေးခြင်းဖြင့် ဤစနစ်များသည် တူးဖော်ရေးလုပ်ငန်းများအား ပိုမိုကောင်းမွန်စွာ ဆောင်ရွက်နိုင်စေပြီး တန်ဖိုးရှိသော သွင်းတူးကိရိယာများကို ကာကွယ်ပေးနိုင်သည်။ သင့်တော်သော အပူချိန်စီမံခန့်ခွဲမှု၏ သက်ရောက်မှုများသည် လုပ်ငန်းဆောင်တာများ၏ အခြေခံအကျိုးကျေးဇူးများကို ကျော်လွန်၍ သွင်းတူးနှုန်းမှ စ၍ တူးခေါင်း၏ တည်ငြိမ်မှုအထိ လွှမ်းခြုံသက်ရောက်နေပါသည်။

ခေတ်မီ ရွှံ့ရည်အေးခဲခြင်းစနစ်များ၏ အဓိကကောင်းကျိုးများ

လုပ်ငန်းစဉ်ကာကွယ်မှုနှင့် အသက်ရှင်ကို တိုး prominently

ခေတ်မီသော တူးစ holes လုပ်ငန်းများသည် အဆင့်မြင့် အောက်ပိုင်းကိရိယာများနှင့် ပစ္စည်းကိရိယာများအပေါ် အလွန်မှီခိုနေပြီး ၎င်းတို့အနက် အပူချိန်များလွန်းပါက ထိခိုက်လွယ်သော ပစ္စည်းများလည်း ပါဝင်ပါသည်။ အဆင့်မြင့် mud cooling systems များသည် အရည်အသွေးကို လက်ခံနိုင်သော အပူချိန်အတွင်း ထိန်းသိမ်းပေးခြင်းဖြင့် ဤရင်းနှီးမြှုပ်နှံမှုများကို ကာကွယ်ရာတွင် အရေးပါသော အခန်းကဏ္ဍမှ ပါဝင်ပါသည်။ drilling fluid အပူချိန်များကို သင့်တော်စွာ ထိန်းချုပ်ပါက ဈေးကြီးသော drilling components များ၏ သက်တမ်းသည် သိသိသာသာ တိုးလာပြီး အစားထိုးစရိတ် လျော့ကျစေကာ လုပ်ငန်းဆောင်တာများ ပိုမိုရပ်တန့်မှု နည်းပါးစေပါသည်။

အပူချိန်မြင့်မားသော ပတ်ဝန်းကျင်များတွင် ထိရောက်သော mud cooling ဖြေရှင်းချက်များကို အသုံးပြုခြင်းဖြင့် ပစ္စည်းကိရိယာများ ပျက်စီးမှုနှုန်းကို ၄၀% အထိ လျော့ကျစေနိုင်ကြောင်း တွေ့ရှိရပါသည်။ ပစ္စည်းကိရိယာများ၏ ယုံကြည်စိတ်ချရမှုတွင် ဤသိသိသာသာ တိုးတက်မှုသည် လုပ်ငန်းများ ရပ်တန့်မှုနှုန်း လျော့ကျစေပြီး ပိုမိုတည်ငြိမ်သော drilling လုပ်ငန်းများကို တိုက်ရိုက် ဖြစ်စေပါသည်။

တူးစ holes လုပ်ငန်း စွမ်းဆောင်ရည် မှတ်တမ်းများ မြှင့်တင်ခြင်း

အပူချိန်ကို အကောင်းဆုံးဖြစ်စေသော တူးဖော်ရေးအရည်များသည် တူးဖော်ရေးစွမ်းဆောင်ရည်ကို သိသိသာသာ မြှင့်တင်ပေးပါသည်။ မြေဆီလွှာအအေးခံစနစ်များက အကောင်းဆုံးအပူချိန်အတွင်း ထိန်းသိမ်းပေးပါက လုပ်ငန်းဆောင်တာများတွင် သော့ချက်စွမ်းဆောင်ရည်ညွှန်းကိန်းများတွင် သိသာထင်ရှားစွာ တိုးတက်မှုများကို လုပ်ငန်းသုံးသူများက တွေ့ရှိရပါသည်။ သင့်တော်သော အအေးခံစနစ်များမရှိသော လုပ်ငန်းများနှင့် နှိုင်းယှဉ်ပါက တူးဖော်နှုန်းသည် ၁၅ မှ ၂၅ ရာခိုင်နှုန်းအထိ တိုးတက်လေ့ရှိပါသည်။

ထို့အပြင် သင့်တော်စွာ အအေးခံထားသော တူးဖော်ရေးအရည်များသည် ၎င်းတို့၏ဒီဇိုင်းပြုလုပ်ထားသော စီးဆင်းမှုဂုဏ်သတ္တိများကို ထိန်းသိမ်းထားပြီး အမှိုက်များကို အကောင်းဆုံးသန့်ရှင်းရေးပြုလုပ်နိုင်စေကာ ပိုက်လိုင်းများ ကပ်ငြိခြင်းအန္တရာယ်ကို လျော့နည်းစေပါသည်။ အရည်၏ ဂုဏ်သတ္တိများတွင် ဤတည်ငြိမ်မှုသည် ပိုမိုခန့်မှန်းနိုင်ပြီး ထိရောက်သော တူးဖော်ရေးလုပ်ငန်းများကို ဖြစ်စေပြီး နောက်ဆုံးတွင် အချိန်နှင့် အရင်းအမြစ်များကို ခြွေတာပေးပါသည်။

ခေတ်မီ မြေဆီလွှာအအေးခံနည်းပညာ၏ နည်းပညာဆိုင်ရာ အချက်များ

ခေတ်မီ အအေးခံစနစ် ပါဝင်ပစ္စည်းများ

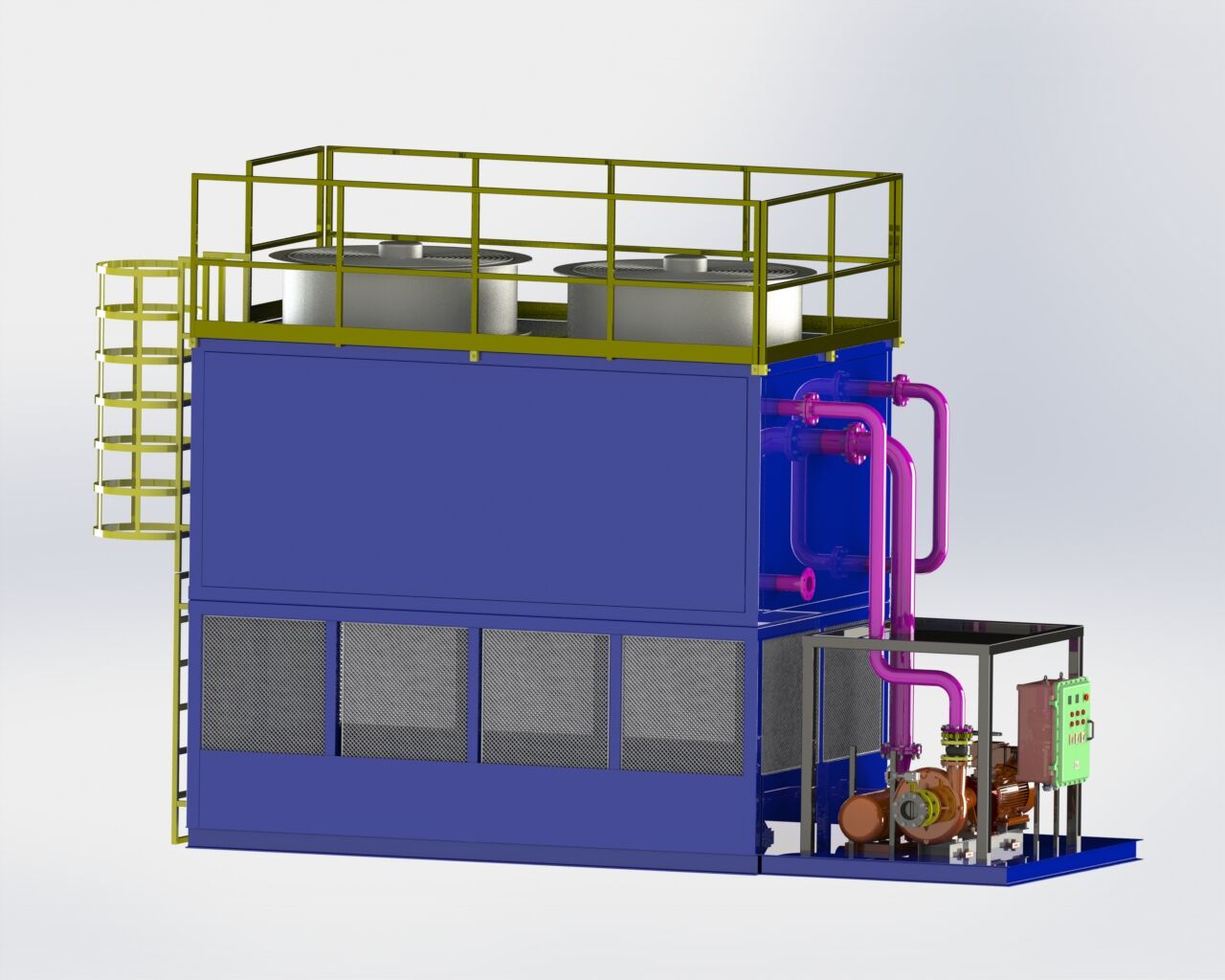

ခေတ်မီသည့် ကျောက်မီးသွေး အအေးခံစနစ်များတွင် ရှုပ်ထွေးသော အပူဖလှယ်မှုနည်းပညာနှင့် ဉာဏ်ရည်မြင့် ထိန်းချုပ်မှုစနစ်များ ပါဝင်ပါသည်။ ဤစနစ်များတွင် အကျိုးရှိမှုမြင့်မားသော ပြားပြားအပူဖလှယ်စက်၊ ခေတ်မီသော စောင့်ကြည့်ရေးဆင်ဆာများနှင့် အလိုအလျောက် အပူချိန်ထိန်းချုပ်မှုစနစ်များ ပါဝင်လေ့ရှိပါသည်။ ဤကွဲပြားသော အစိတ်အပိုင်းများ ပေါင်းစပ်ခြင်းဖြင့် တူးဖော်ရေးလုပ်ငန်းစဉ်တစ်လျှောက် တိကျသော အပူချိန်ထိန်းချုပ်မှုကို သေချာစေပါသည်။

ခေတ်မီသော အအေးခံယူနစ်များကို အလွဲမှားများကို ကာကွယ်ရန် ဒီဇိုင်းထုတ်ထားပြီး အများအားဖြင့် အအေးခံစက်များစွာနှင့် နောက်ထပ်စနစ်များ ပါဝင်ကာ လုပ်ငန်းဆောင်တာများ မပျက်ကွက်စေရန် ကာကွယ်ပေးပါသည်။ ဤနောက်ထပ်စနစ်များသည် အချိန်နှင့်တစ်ပြေးညီ စောင့်ကြည့်နိုင်မှုနှင့် တွဲဖက်ခြင်းဖြင့် တူးဖော်ရေးအရည်များ၏ အပူချိန်ကို ယခင်မကြုံဖူးသော ထိန်းချုပ်မှုကို လုပ်ငန်းလည်ပတ်သူများအား ပေးစွမ်းပါသည်။

ရှိပြီးသား တူးဖော်ရေးစနစ်များနှင့် ပေါင်းစပ်ခြင်း

မြေဆီလွှာကို အေးခဲအောင်ပြုလုပ်သည့်နည်းပညာကို အောင်မြင်စွာ အကောင်အထည်ဖော်ရန်အတွက် လက်ရှိတူးဖော်ရေး အခြေခံအဆောက်အအုံများနှင့် အပြောင်းအလဲမရှိဘဲ ပေါင်းစပ်နိုင်ရန် လိုအပ်ပါသည်။ ခေတ်မီစနစ်များကို ပေါင်းစပ်အသုံးပြုနိုင်မှုကို ထည့်သွင်းစဉ်းစား၍ စံသတ်မှတ်ထားသော ချိတ်ဆက်မှုများနှင့် ပြောင်းလဲအသုံးပြုနိုင်သော ထိန်းချုပ်မှု အင်တာဖေ့စ်များဖြင့် ဒီဇိုင်းထုတ်ထားပါသည်။ ဤပြောင်းလဲနိုင်မှုရှိမှုသည် လက်ရှိစနစ်တွင် ကြီးမားသော ပြုပြင်မွမ်းမံမှုများ မလိုအပ်ဘဲ အပူချိန်စီမံခန့်ခွဲမှုစွမ်းရည်ကို မြှင့်တင်နိုင်စေပါသည်။

ခေတ်မီ စောင့်ကြည့်ထိန်းချုပ်မှုစနစ်များသည် တူးဖော်ရေးအခြေအနေများ ပြောင်းလဲလာသည်နှင့်အမျှ အေးခဲမှု ပါရာမီတာများကို အချိန်နှင့်တစ်ပြေးညီ ချိန်ညှိနိုင်စေပါသည်။ ဤပြောင်းလဲနိုင်စွမ်းရှိမှုသည် အနက်အဆင့်များနှင့် မြေဆီလွှာအမျိုးအစားများစွာတွင် အကောင်းဆုံးစွမ်းဆောင်ရည်ကို သေချာစေပါသည်။

ခေတ်မီ မြေဆီလွှာအေးခဲမှု၏ စီးပွားရေးဆိုင်ရာ အကျိုးသက်ရောက်မှုများ

အစောဆုံးရင်းနှီးမြှုပ်နှံမှုစဉ်းစားရမည့်အချက်များ

အဆင့်မြင့် ကျောက်မီးသွေး အအေးပေးစနစ်များ တပ်ဆင်ခြင်းသည် အစပိုင်းတွင် သိသိသာသာ ရင်းနှီးမြှုပ်နှံမှု လိုအပ်သော်လည်း ရေရှည်တွင် ရရှိမည့် ငွေကြေး အကျိုးကျေးဇူးများက ထိုကုန်ကျစရိတ်ကို ဖြေရှင်းနိုင်ပါသည်။ စက်ကိရိယာများနှင့် တပ်ဆင်မှု ကုန်ကျစရိတ်များကိုသာမက တူးဖော်ရေး ထိရောက်မှု ပိုမိုကောင်းမွန်လာခြင်းနှင့် ရပ်တန့်မှု ကာလ လျော့နည်းလာခြင်းတို့မှ ရရှိနိုင်သော အမြတ်အစွန်းများကိုပါ စဉ်းစားရန် လုပ်ငန်းလည်ပတ်သူများ လိုအပ်ပါသည်။

အဆင့်မြင့် ကျောက်မီးသွေး အအေးပေးစနစ်များ အသုံးပြုသော လုပ်ငန်းများသည် စီမံကိန်း၏ သက်တမ်းတစ်လျှောက် ပိုမိုကောင်းမွန်သော ဘဏ္ဍာရေး ရလဒ်များ ရရှိကြောင်း ကုန်ကျစရိတ်နှင့် အကျိုးကျေးဇူး ဆန်းစစ်ချက်များက အမြဲတမ်း ပြသပါသည်။ စက်ကိရိယာများ ပျက်စီးမှု လျော့နည်းခြင်း၊ တူးဖော်နှုန်း ပိုမိုကောင်းမွန်လာခြင်းနှင့် ထုတ်လုပ်မှုမရှိသော အချိန်ကို လျော့နည်းစေခြင်းတို့ကြောင့် ရင်းနှီးမြှုပ်နှံမှု ပြန်လည်ရရှိမှုကို ၁၂ မှ ၁၈ လအတွင်း ရရှိလေ့ရှိပါသည်။

ကာလရှည် စီးပွားရေးဆိုင်ရာ ကုန်ကျစရိတ် အကျိုးကျေးဇူးများ

ကျောက်မီးသွေးကို သင့်တော်စွာ အအေးပေးခြင်း၏ ဘဏ္ဍာရေး အကျိုးကျေးဇူးများသည် စီမံကိန်း၏ အစပိုင်းကာလကို ကျော်လွန်၍ ရေရှည်တွင် ဆက်လက်ရရှိနိုင်ပါသည်။ စက်ကိရိယာများ ပိုမိုကြာရှည်စွာ အသုံးပြုနိုင်ခြင်းနှင့် ပျက်စီးမှု ဖြစ်ရပ်များ လျော့နည်းခြင်းတို့ကြောင့် ပုံမှန် ထိန်းသိမ်းမှု ကုန်ကျစရိတ်များသည် ၂၅ မှ ၃၀ ရာခိုင်နှုန်း လျော့နည်းလေ့ရှိပါသည်။ ထို့အပြင် တူးဖော်ရေး ထိရောက်မှု ပိုမိုကောင်းမွန်လာခြင်းကြောင့် စီမံကိန်း ကာလများ ပိုတိုတောင်းလာပြီး စုစုပေါင်း လုပ်ငန်းဆိုင်ရာ ကုန်ကျစရိတ်များတွင် သိသိသာသာ ခြွေတာနိုင်ပါသည်။

ခေတ်မီသော အအေးပေးစနစ်များတွင် စွမ်းအင်ထိရောက်မှု မြှင့်တင်မှုများသည် လည်ပတ်စရိတ်ကိုလည်း လျော့နည်းစေပါသည်။ နောက်ဆုံးပေါ် အအေးပေးယူနစ်များသည် ယခင်စနစ်များထက် 20-30% လျော့နည်းသော ဓာတ်အားကို သုံးစွဲပြီး ပိုမိုကောင်းမွန်သော အပူချိန်ထိန်းချုပ်မှုစွမ်းရည်ကို ပေးစွမ်းနိုင်ပါသည်။

ပরিবেশနှင့် အားကစားရေး မူဝါဒများ

ပတ်ဝန်းကျင်သက်ရောက်မှု လျော့ချခြင်း

မြေပြင်တူးဖော်ရေးလုပ်ငန်းများတွင် ပတ်ဝန်းကျင်သက်ရောက်မှုကို လျော့နည်းစေရန် တိုးတက်သော ကျောက်မုန်လားအအေးပေးစနစ်များက အဓိကအထောက်အကူပြုပါသည်။ အရည်၏ ဂုဏ်သတ္တိများကို အကောင်းဆုံးဖြစ်အောင် ထိန်းသိမ်းခြင်းဖြင့် အရည်ကို အကြိမ်ကြိမ်လဲလှယ်ရန် လိုအပ်မှုကို လျော့နည်းစေပြီး အမှိုက်ထုတ်လုပ်မှုနှင့် စွန့်ပစ်မှုလိုအပ်ချက်များကို လျော့နည်းစေပါသည်။ ခေတ်မီအအေးပေးယူနစ်များတွင် ရေသုံးဆုံးမှုကို လျော့နည်းစေပြီး ညစ်ညမ်းမှုအန္တရာယ်များကို ကာကွယ်နိုင်သော ပိတ်ထားသည့် စက်ဝန်းဒီဇိုင်းများပါဝင်ပါသည်။

တူးဖော်ရေးလုပ်ငန်းများတွင် ပိုမိုကောင်းမွန်သော ထိရောက်မှုသည် ပရောဂျက်ကာလကိုတိုစေခြင်းနှင့် စွမ်းအင်သုံးစွဲမှုကို လျော့နည်းစေခြင်းဖြင့် ကာဗွန်ဓာတ်ငွေ့ထုတ်လွှတ်မှုကို တိုက်ရိုက်လျော့နည်းစေပါသည်။ ဤပတ်ဝန်းကျင်ဆိုင်ရာ အကျိုးကျေးဇူးသည် ရေရှည်တည်တံ့သော တူးဖော်ရေးလုပ်ငန်းများအပေါ် လုပ်ငန်းစုံတိုးမြှင့်လာသော အာရုံစိုက်မှုနှင့် ကောင်းစွာကိုက်ညီပါသည်။

အောင်မြင်သည့် ရိုက်ပါးနိုင်ချက်

အပူချိန်စီမံခန့်ခွဲမှုသည် လုံခြုံသော တူးဖော်ရေးလုပ်ငန်းများကို ထိန်းသိမ်းရာတွင် အရေးပါသော အခန်းကဏ္ဍမှ ပါဝင်ပါသည်။ ပူလွန်းသော ပစ္စည်းကိရိယာများ သို့မဟုတ် အရည်၏ ဂုဏ်သတ္တိများ ပျက်ပြားခြင်းမှ ဖြစ်ပေါ်လာနိုင်သော အန္တရာယ်ရှိသည့် အခြေအနေများကို ကာကွယ်ရာတွင် တိုးတက်သော ကျောက်မီးသွေး အအေးပေးစနစ်များ အထောက်အကူပြုပါသည်။ သင့်တော်သော အပူချိန်ထိန်းချုပ်မှုမှ ဖန်တီးသည့် တည်ငြိမ်သော လုပ်ဆောင်မှုအခြေအနေများသည် တူးစင်၏ တည်ငြိမ်မှုပြဿနာများနှင့် အခြားသော လုံခြုံရေးအရ အရေးကြီးသည့် ဖြစ်ရပ်များ၏ အန္တရာယ်ကို လျော့နည်းစေပါသည်။

ခေတ်မီသော အအေးပေးစနစ်များတွင် ဖြစ်နိုင်ခြေရှိသော ပြဿနာများကို ကြိုတင်သတိပေးသည့် တိုးတက်သော လုံခြုံရေးလုပ်ဆောင်ချက်များနှင့် စောင့်ကြည့်မှုစွမ်းရည်များကို ပေါင်းစပ်ထားပြီး ပြဿနာများ ပိုမိုဆိုးရွားလာမည်မီ လုပ်ငန်းသုံးသူများအနေဖြင့် ကာကွယ်ရေးအရေးယူမှုများ ဆောင်ရွက်နိုင်စေပါသည်။

မေးလေ့ရှိသောမေးခွန်းများ

တူးဖော်ရေးအရည်များအတွက် ဘယ်လောက်အပူချိန်ကို အကောင်းဆုံးအဖြစ် မှတ်ယူထားပါသလဲ။

တူးဖော်ရေးအရည်များအတွက် အကောင်းဆုံးအပူချိန်များသည် အသုံးပြုမှုလိုအပ်ချက်များနှင့် မြေအောက်အခြေအနေများပေါ်မူတည်၍ ပုံမှန်အားဖြင့် 120°F မှ 150°F (49°C မှ 66°C) အတွင်းတွင် ရှိပါသည်။ ဤအပူချိန်အတွင်း ထိန်းသိမ်းခြင်းသည် အရည်၏ဂုဏ်သတ္တိများကို ထိန်းသိမ်းရာတွင်နှင့် တူးဖော်ရေးပစ္စည်းကိရိယာများကို ကာကွယ်ရာတွင် အထောက်အကူပြုပါသည်။

တိုးတက်သော ကျောက်မီးသွေး အအေးပေးစနစ်များသည် အပူချိန်ပြောင်းလဲမှုကို မည်မျှမြန်မြန် တုံ့ပြန်နိုင်ပါသလဲ။

ခေတ်မီသည့် ကျောက်မီးသွေး အအေးခံစနစ်များသည် စနစ်၏ စွမ်းဆောင်ရည်နှင့် အပူချိန် ပြောင်းလဲမှုအပေါ် မူတည်၍ ပြောင်းလဲမှုကို စတင်ဖော်ထုတ်ပြီး ၅ မှ ၁၅ မိနစ်အတွင်း အအေးဓာတ်ပါ အရည်၏ အပူချိန်ကို ပြင်ဆင်နိုင်ပါသည်။ တိုးတက်သော ထိန်းချုပ်မှုစနစ်များက အခြေအနေများ ပြောင်းလဲလာပါက မြန်ဆန်စွာ တုံ့ပြန်နိုင်ပြီး စနစ် တည်ငြိမ်စွာ လည်ပတ်နိုင်စေပါသည်။

တိုးတက်သော ကျောက်မီးသွေး အအေးခံစနစ်များတွင် မည်သည့် ထိန်းသိမ်းမှုလိုအပ်ချက်များ ရှိပါသနည်း။

တိုးတက်သော ကျောက်မီးသွေး အအေးခံစနစ်များတွင် အပူဖလှယ်စက် သန့်ရှင်းရေး၊ ဆင်ဆာများ ဂျီဩမီတြိက် ပြင်ဆင်မှုနှင့် စနစ်၏ စွမ်းဆောင်ရည် စစ်ဆေးမှုများ စသည့် ပုံမှန် ထိန်းသိမ်းမှုများ လိုအပ်ပါသည်။ ပုံမှန် ထိန်းသိမ်းမှု ကာလများသည် တစ်ပတ်လျှင် တစ်ကြိမ် စစ်ဆေးမှုမှ တစ်နှစ်လျှင် တစ်ကြိမ် အဓိက ဝန်ဆောင်မှု လိုအပ်ချက်အထိ ကွာခြားနိုင်ပြီး အသေးစိတ် အချိန်ဇယားများမှာ လည်ပတ်မှု အခြေအနေများနှင့် စနစ်ဒီဇိုင်းအပေါ် မူတည်ပါသည်။

ဖိအားမြင့် အပူချိန်မြင့် (HPHT) တွင်းများတွင် ကျောက်မီးသွေး အအေးခံခြင်းသည် မြေဖော်ခြင်းကို မည်သို့ သက်ရောက်မှု ရှိပါသနည်း။

HPHT တွင်းများတွင် ထွန်းလှော်ရေအခြေအနေများကို တည်ငြိမ်စေရန်နှင့် တွင်းအောက်ပစ္စည်းကိရိယာများကို ကာကွယ်ရန်အတွက် ထိရောက်သော မတ်စပ်အေးခဲခြင်းသည် အလွန်အရေးကြီးပါသည်။ အဆင့်မြင့် အေးခဲမှုစနစ်များသည် 300°F (149°C) ကျော်လွန်သော အပူချိန်များရှိသည့် ပတ်ဝန်းကျင်များတွင် ထွန်းလှော်ရေ၏ ဂုဏ်သတ္တိများကို ထိန်းသိမ်းပေးခြင်းဖြင့် ပစ္စည်းကိရိယာများ ပျက်စီးခြင်းမှ ကာကွယ်ပေးကာ ထွန်းလှော်မှုကို ဖြစ်နိုင်စေပါသည်။

အကြောင်းအရာများ

- တူးဖော်ရေးလုပ်ငန်းများတွင် အပူချိန်ထိန်းချုပ်မှု၏ သက်ရောက်မှုကို နားလည်ခြင်း

- ခေတ်မီ ရွှံ့ရည်အေးခဲခြင်းစနစ်များ၏ အဓိကကောင်းကျိုးများ

- ခေတ်မီ မြေဆီလွှာအအေးခံနည်းပညာ၏ နည်းပညာဆိုင်ရာ အချက်များ

- ခေတ်မီ မြေဆီလွှာအေးခဲမှု၏ စီးပွားရေးဆိုင်ရာ အကျိုးသက်ရောက်မှုများ

- ပরিবেশနှင့် အားကစားရေး မူဝါဒများ

-

မေးလေ့ရှိသောမေးခွန်းများ

- တူးဖော်ရေးအရည်များအတွက် ဘယ်လောက်အပူချိန်ကို အကောင်းဆုံးအဖြစ် မှတ်ယူထားပါသလဲ။

- တိုးတက်သော ကျောက်မီးသွေး အအေးပေးစနစ်များသည် အပူချိန်ပြောင်းလဲမှုကို မည်မျှမြန်မြန် တုံ့ပြန်နိုင်ပါသလဲ။

- တိုးတက်သော ကျောက်မီးသွေး အအေးခံစနစ်များတွင် မည်သည့် ထိန်းသိမ်းမှုလိုအပ်ချက်များ ရှိပါသနည်း။

- ဖိအားမြင့် အပူချိန်မြင့် (HPHT) တွင်းများတွင် ကျောက်မီးသွေး အအေးခံခြင်းသည် မြေဖော်ခြင်းကို မည်သို့ သက်ရောက်မှု ရှိပါသနည်း။