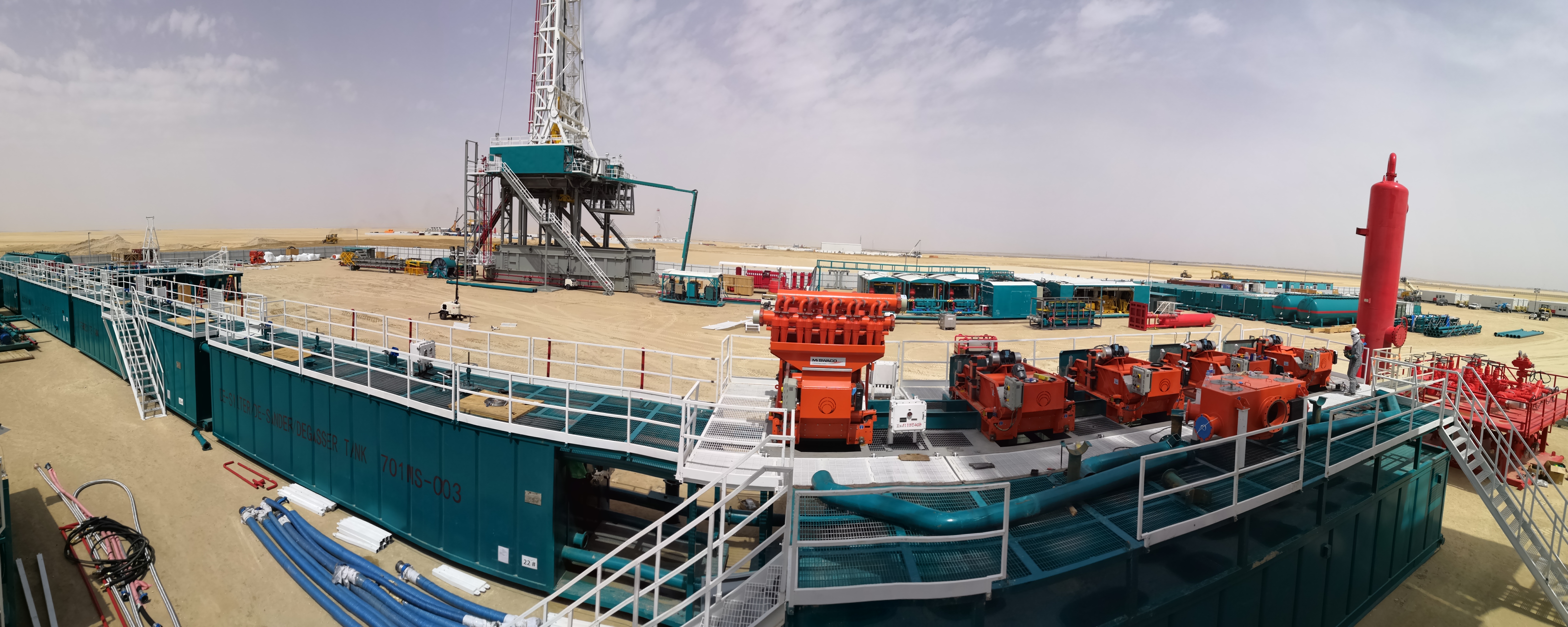

drill cuttings dewatering system

A drill cuttings dewatering system is an advanced technological solution designed to efficiently separate and process drilling waste materials from drilling operations. This sophisticated system employs a combination of mechanical and chemical processes to effectively separate liquids from solids, significantly reducing waste volume and recovering valuable drilling fluids. The system typically consists of multiple components including shale shakers, centrifuges, chemical treatment units, and collection tanks working in harmony to achieve optimal separation results. In operation, the system first receives drill cuttings laden with drilling fluids, processes them through various separation stages, and ultimately produces dry solid waste suitable for disposal or repurposing, while simultaneously recovering reusable drilling fluids. The technology incorporates advanced monitoring systems and automated controls to maintain consistent performance and ensure compliance with environmental regulations. This system proves particularly valuable in both onshore and offshore drilling operations, where waste management and environmental considerations are paramount. The dewatering process not only minimizes environmental impact but also provides substantial cost savings through the recovery and reuse of expensive drilling fluids. Modern systems are designed with mobility in mind, allowing for easy transportation between drilling sites and quick setup times.