drilling waste management and tank cleaning

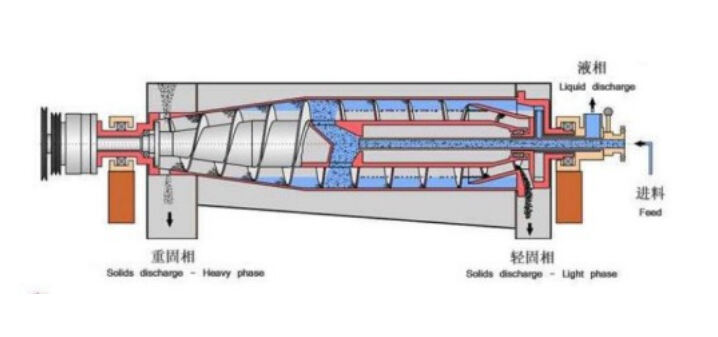

Drilling waste management and tank cleaning represents a critical component of modern industrial operations, encompassing comprehensive solutions for handling, treating, and disposing of drilling-related waste materials while maintaining clean and efficient storage systems. This integrated approach combines advanced technologies, environmental compliance measures, and innovative cleaning methodologies to ensure optimal operational efficiency. The process involves sophisticated waste separation techniques, including mechanical and chemical treatment systems, that effectively segregate solid particles, hydrocarbons, and water. State-of-the-art equipment such as centrifuges, thermal desorption units, and high-pressure cleaning systems work in conjunction to process drilling fluids, cuttings, and other waste materials. Tank cleaning operations utilize automated systems with rotating jet heads and environmentally friendly cleaning agents to remove sediments, sludge, and contaminated materials from storage vessels. These services are essential across various industries, including oil and gas exploration, petrochemical processing, and industrial manufacturing, where proper waste management and equipment maintenance are paramount to operational success and environmental compliance.