highpressure cleaning equipment for oilbased mud tanks

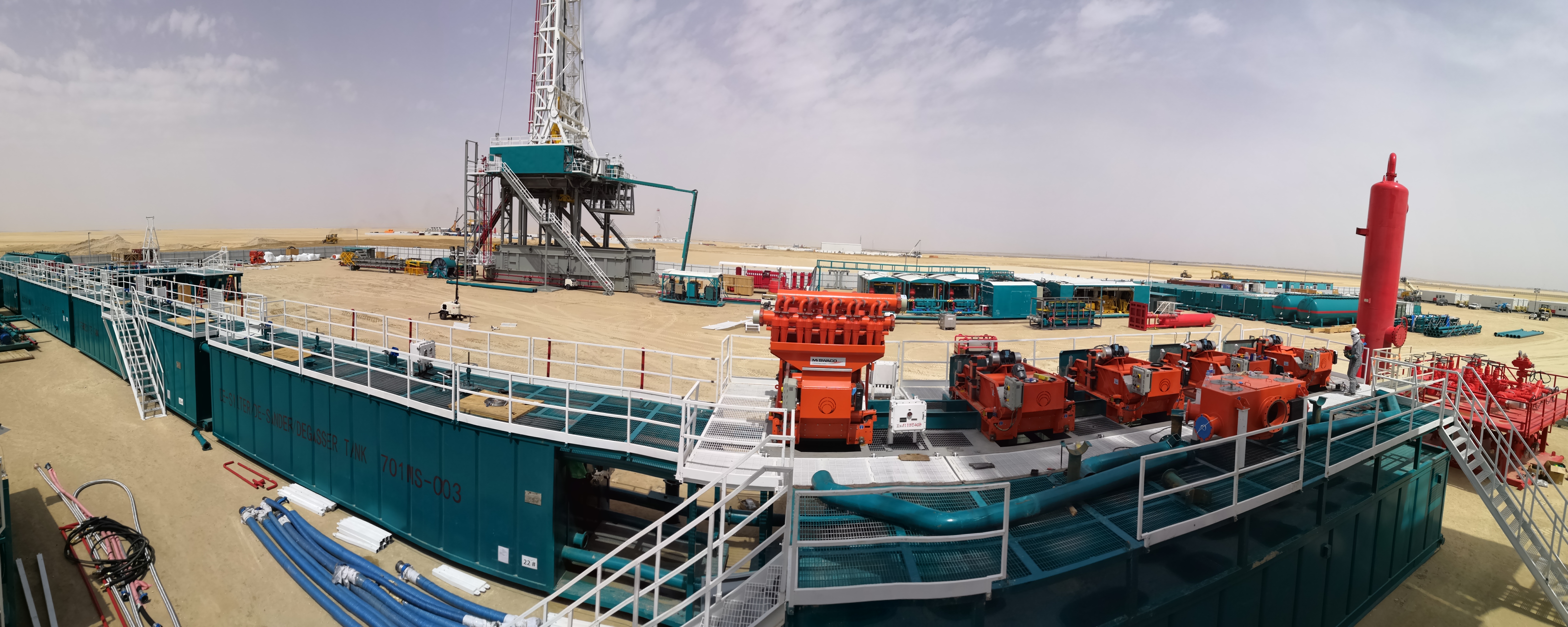

High-pressure cleaning equipment for oil-based mud tanks represents a cutting-edge solution in the oil and gas industry's maintenance operations. This specialized equipment utilizes advanced pressure technology to effectively remove stubborn oil-based mud residues, ensuring thorough cleaning of storage tanks. The system typically operates at pressures ranging from 3,000 to 10,000 PSI, delivering powerful water jets that can dislodge and remove even the most persistent mud deposits. The equipment features adjustable pressure settings, specialized nozzles designed for different cleaning angles, and automated cleaning patterns that ensure complete coverage of tank surfaces. These systems are equipped with safety mechanisms including emergency shut-offs and pressure relief valves. The equipment's versatility allows it to clean various tank sizes and configurations, while its mobility enables easy transportation between different sites. Modern units incorporate water recycling systems and filtration technology to minimize environmental impact and reduce water consumption. The technology proves particularly valuable in maintaining drilling operations' efficiency by reducing downtime and ensuring environmental compliance.