mining waste treatment

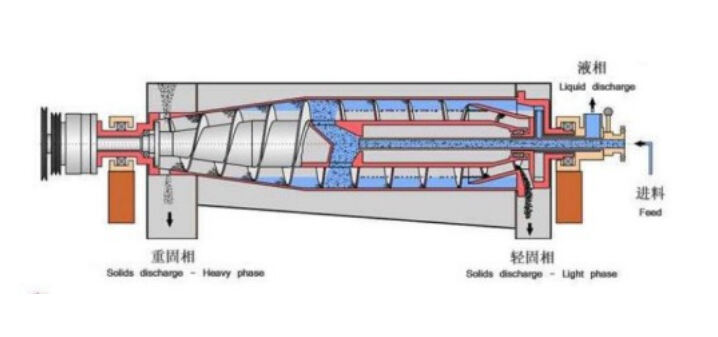

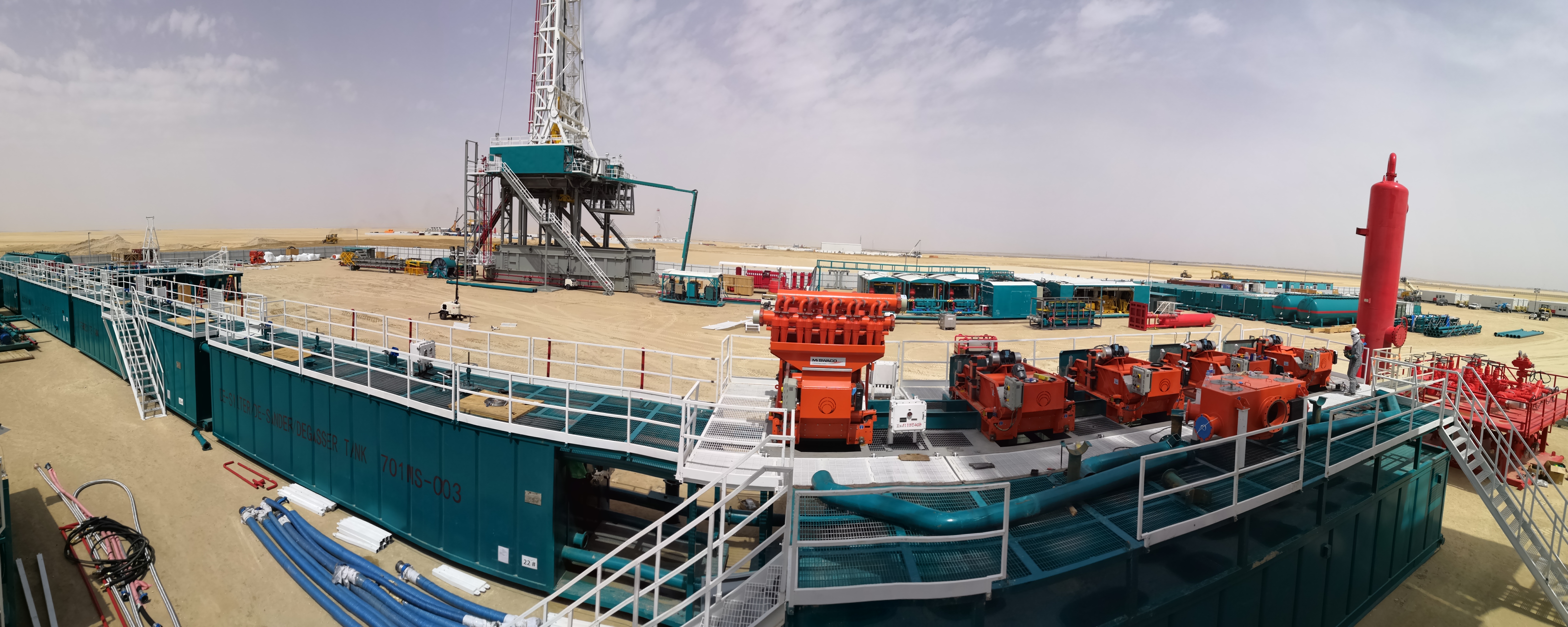

Mining waste treatment is a comprehensive process designed to manage and mitigate the environmental impact of waste materials generated during mining operations. This essential process incorporates various technological solutions to handle tailings, waste rock, and other mining by-products effectively. The treatment system typically employs multiple stages, including physical separation, chemical processing, and biological remediation techniques. Advanced filtration systems remove harmful substances while recovering valuable minerals, making the process both environmentally responsible and economically viable. The treatment facilities are equipped with state-of-the-art monitoring systems that ensure compliance with environmental regulations and maintain optimal performance levels. Key functions include the reduction of toxic elements, water recovery and recycling, and the stabilization of waste materials for safe storage or potential reuse. Modern mining waste treatment systems are designed to handle large volumes of waste while minimizing energy consumption and operating costs. The technology adapts to different types of mining operations, from metal ore processing to coal mining, offering customized solutions for specific waste compositions and environmental requirements. These systems also incorporate automation and digital control mechanisms, enabling real-time adjustments and efficient operation management.