dairy byproduct recovery centrifuge

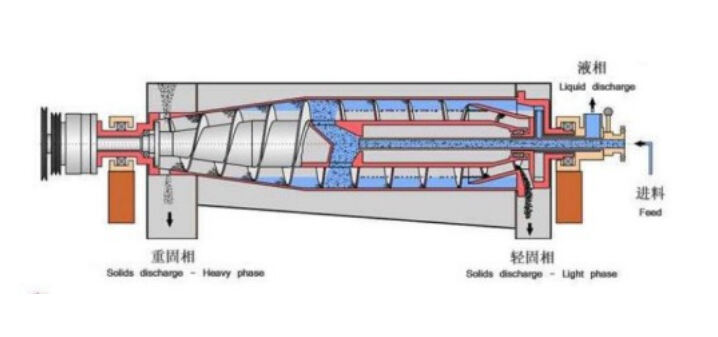

The dairy byproduct recovery centrifuge represents a cutting-edge solution in modern dairy processing, designed to maximize resource utilization and minimize waste in dairy operations. This sophisticated piece of equipment employs high-speed centrifugal force to separate and recover valuable components from dairy processing streams that might otherwise be discarded. The centrifuge operates by spinning the dairy byproducts at precisely controlled speeds, effectively separating different components based on their specific gravity. This process enables the recovery of valuable proteins, fats, and other nutritional components from whey, wash water, and other dairy processing streams. The technology incorporates advanced automation systems that maintain optimal separation conditions while ensuring consistent product quality. The machine's design features specialized disc stacks that enhance separation efficiency, along with automated cleaning systems that maintain hygiene standards. Applications span across various dairy processing operations, including cheese manufacturing, yogurt production, and butter making, where it recovers valuable components from processing streams. The system's versatility allows it to handle different types of dairy byproducts, making it an essential tool in modern dairy facilities focused on sustainability and resource optimization.