oil drilling solids control equipment

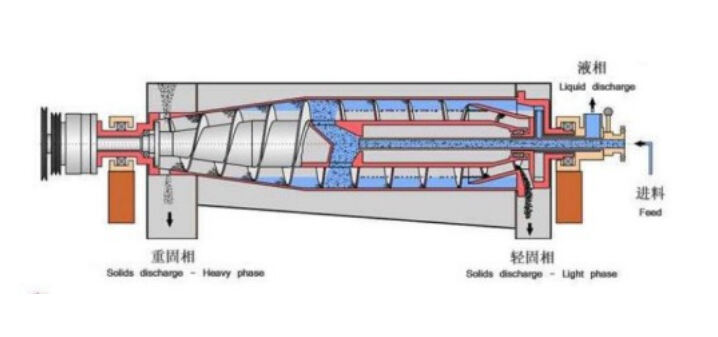

Oil drilling solids control equipment represents a crucial system in modern drilling operations, designed to efficiently separate and manage various types of solids from drilling fluids. This integrated system typically consists of multiple components including shale shakers, hydrocyclones, centrifuges, and mud cleaners, working in harmony to maintain optimal drilling fluid properties. The primary function is to remove unwanted solids from the drilling mud, which is essential for maintaining drilling efficiency and protecting downhole equipment. The system operates through a series of mechanical and hydraulic separation processes, utilizing cutting-edge technology to handle different particle sizes and types of drilling waste. Advanced sensors and automated controls ensure precise separation efficiency, while robust construction materials withstand harsh drilling environments. The equipment processes drilling fluid in real-time, allowing for continuous drilling operations while maintaining the required mud properties. This technology has evolved to meet increasingly stringent environmental regulations and operational demands, incorporating features such as automatic adjustment capabilities and remote monitoring systems. The applications span across onshore and offshore drilling operations, from shallow wells to deep-water drilling projects, making it an indispensable component in modern oil and gas exploration.