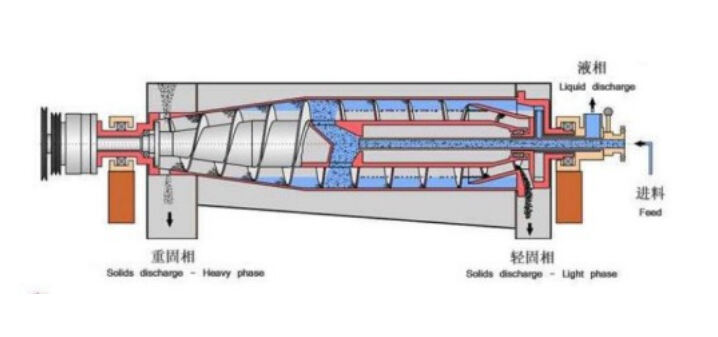

oily wastewater separation centrifuge

The oily wastewater separation centrifuge represents a cutting-edge solution for efficient liquid-liquid separation in industrial processes. This advanced equipment utilizes centrifugal force to separate oil from water based on their different densities. Operating at high rotational speeds, the centrifuge creates a powerful gravitational field that accelerates the separation process, making it significantly more effective than traditional gravity settling methods. The device features a precisely engineered rotating bowl system that continuously processes incoming wastewater, separating it into distinct oil and water phases. The separated oil can be recovered for potential reuse, while the cleaned water meets environmental discharge standards. The centrifuge's automated control system maintains optimal separation efficiency through real-time monitoring and adjustment of operational parameters. This technology finds widespread application across various industries, including oil and gas, petrochemical processing, food processing, and manufacturing facilities where oil-contaminated wastewater is a common challenge. The system's ability to handle varying concentrations of oil and different types of emulsions makes it particularly versatile for industrial applications. Modern designs incorporate advanced features such as automatic sludge discharge systems, variable frequency drives for energy efficiency, and sophisticated monitoring capabilities for consistent performance.