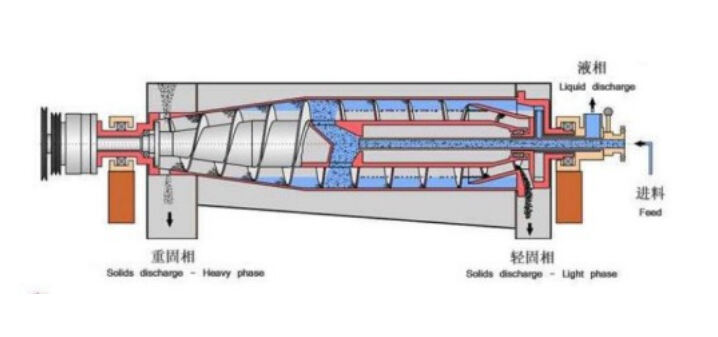

decanter centrifuge for sludge dewatering and recycling

A decanter centrifuge is an advanced technological solution designed specifically for sludge dewatering and recycling processes. This sophisticated equipment operates through continuous centrifugal force separation, effectively dividing waste materials into solid and liquid components. The machine consists of a horizontal cylindrical bowl that rotates at high speeds, creating powerful centrifugal forces that separate materials based on their specific gravity. Inside, a scroll conveyor rotates at a slightly different speed than the bowl, continuously moving separated solids toward the discharge end. The system efficiently processes various types of sludge, including municipal wastewater, industrial waste, and agricultural byproducts. The technology employs precise control systems to optimize separation efficiency, allowing for adjustable differential speeds between the bowl and scroll conveyor. This flexibility enables the equipment to handle different sludge consistencies and achieve optimal dewatering results. Modern decanter centrifuges incorporate advanced features such as automatic torque control, variable speed drives, and programmable logic controllers, ensuring consistent performance and reduced operator intervention. The equipment's design facilitates continuous operation, making it ideal for large-scale waste treatment facilities and industrial applications where consistent sludge processing is essential.