waste oil sludge treatment

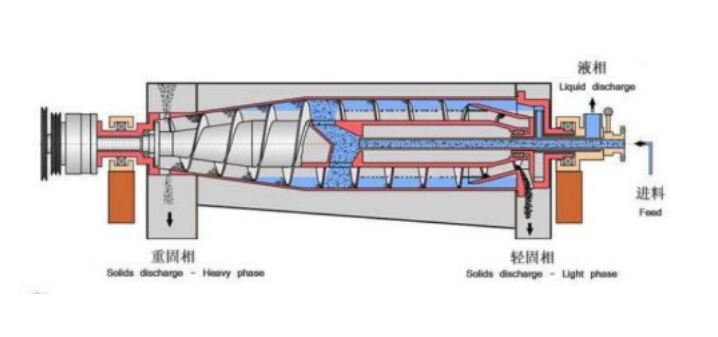

Waste oil sludge treatment represents a critical environmental solution designed to process and recover valuable resources from oil-contaminated waste materials. This advanced treatment system employs multiple stages of separation and purification to effectively handle various types of oil sludge generated by industrial operations. The process begins with a preliminary screening phase that removes large solid particles, followed by sophisticated thermal desorption technology that separates oil, water, and solids. The system utilizes cutting-edge centrifugal separation combined with chemical treatment to achieve optimal results. A key feature is its ability to process high-viscosity sludge through specialized heating mechanisms that maintain optimal processing temperatures. The technology incorporates automated control systems that monitor and adjust treatment parameters in real-time, ensuring consistent quality output. Applications span across multiple industries, including petroleum refineries, manufacturing facilities, and environmental remediation projects. The treated oil can be recycled for industrial use, while the cleaned solids often meet environmental standards for safe disposal or repurposing. This treatment solution addresses both environmental compliance requirements and resource recovery objectives, making it an essential tool for modern industrial waste management.