The oil and gas industry faces increasing environmental regulations and cost pressures when managing drilling waste materials. Proper handling of water-based drilling cuttings has become a critical operational requirement that directly impacts project economics and environmental compliance. Understanding the characteristics, treatment methods, and disposal options for these materials enables drilling operators to optimize their waste management strategies while maintaining regulatory adherence.

Modern drilling operations generate substantial volumes of cuttings that require immediate processing to prevent operational delays and environmental issues. The composition of water-based drilling cuttings varies significantly depending on geological formations, drilling fluid formulations, and operational parameters. Effective management systems must account for these variables while providing consistent treatment performance across different drilling scenarios.

Understanding Water-Based Drilling Cuttings Composition

Physical Characteristics and Properties

Water-based drilling cuttings consist primarily of rock fragments removed during the drilling process, combined with residual drilling fluid components. The particle size distribution typically ranges from fine clay particles to larger rock fragments, creating a heterogeneous mixture that requires specialized handling equipment. Moisture content in these materials generally varies between 15% and 40%, depending on formation characteristics and drilling fluid properties.

The density of water-based drilling cuttings fluctuates based on the geological formation being drilled and the specific gravity of the drilling fluid system. Clay-rich formations tend to produce cuttings with higher water retention capabilities, while sandstone formations generate more porous materials that drain more readily. Understanding these physical properties enables operators to select appropriate treatment technologies and optimize processing parameters.

Chemical Components and Environmental Considerations

The chemical composition of water-based drilling cuttings includes both naturally occurring minerals from the drilled formation and additives from the drilling fluid system. Common drilling fluid additives include bentonite clay, polymers, weighting agents like barite, and various chemical treatments for pH control and corrosion inhibition. These components must be carefully evaluated for potential environmental impacts and disposal restrictions.

Environmental regulations typically focus on hydrocarbon content, heavy metals, and chloride concentrations in drilling waste materials. Water-based systems generally produce cuttings with lower hydrocarbon content compared to oil-based alternatives, making them more suitable for certain disposal methods. However, elevated salt concentrations from formation brines can create challenges for land application and require specific treatment approaches.

Treatment Technologies and Processing Methods

Mechanical Separation Techniques

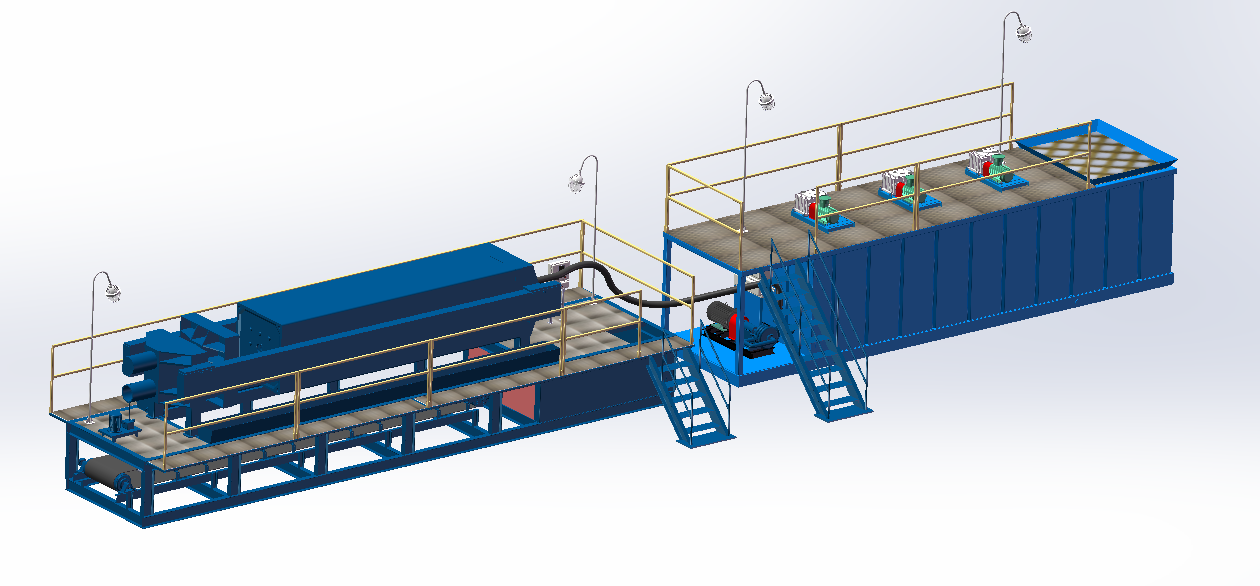

Mechanical separation represents the primary treatment approach for water-based drilling cuttings, utilizing physical forces to remove excess moisture and recover valuable drilling fluid components. Shale shakers provide the initial separation stage, removing larger cuttings while allowing drilling fluid to return to the active system. Screen mesh selection and vibration parameters significantly influence separation efficiency and drilling fluid recovery rates.

Centrifugal separation technologies offer enhanced performance for fine particle removal and moisture reduction in drilling cuttings. High-speed centrifuges generate substantial gravitational forces that separate solids based on density differences, achieving moisture reductions of 60% to 80% in properly designed systems. These units require careful maintenance and operational monitoring to maintain optimal performance levels.

Thermal Treatment and Drying Systems

Thermal drying systems provide the most effective moisture removal for water-based drilling cuttings, achieving final moisture contents below 5% when properly operated. Direct-fired dryers utilize combustion gases to heat and evaporate moisture, while indirect systems use heat exchangers to prevent contamination of the treated materials. Temperature control and residence time management are critical factors for preventing material degradation and ensuring consistent treatment performance.

Advanced thermal treatment systems incorporate heat recovery technologies to improve energy efficiency and reduce operating costs. Waste heat from the drying process can be captured and reused for preheating incoming materials or generating process steam. These systems require significant capital investment but provide superior treatment performance and operational flexibility for varying waste stream characteristics.

Regulatory Compliance and Environmental Standards

Federal and State Regulations

Environmental regulations governing water-based drilling cuttings management vary significantly across different jurisdictions and drilling locations. Federal regulations under the Clean Water Act and Resource Conservation and Recovery Act establish baseline requirements for waste characterization, treatment, and disposal activities. State regulations often impose additional restrictions based on local environmental conditions and groundwater protection requirements.

Permit requirements for drilling waste management facilities typically include detailed operational procedures, monitoring protocols, and reporting obligations. Operators must demonstrate compliance with discharge limits, air quality standards, and waste handling requirements through comprehensive documentation and regular testing programs. Non-compliance can result in significant penalties and operational shutdowns.

Best Management Practices

Implementation of best management practices ensures consistent regulatory compliance and minimizes environmental risks associated with water-based drilling cuttings handling. These practices include proper waste characterization protocols, appropriate containment systems, and regular equipment maintenance programs. Staff training and procedural documentation help maintain operational consistency and prevent regulatory violations.

Environmental monitoring programs provide early detection of potential issues and demonstrate ongoing compliance with regulatory requirements. Groundwater monitoring, air quality testing, and soil sampling around treatment facilities help identify any environmental impacts and enable prompt corrective actions. Regular auditing and continuous improvement processes enhance overall environmental performance.

Economic Optimization Strategies

Cost-Benefit Analysis of Treatment Options

Economic evaluation of water-based drilling cuttings treatment alternatives requires comprehensive analysis of capital costs, operating expenses, and long-term disposal obligations. Treatment technologies with higher initial investments may provide superior long-term economics through reduced disposal costs and improved regulatory compliance. Operators must consider project duration, waste volumes, and local disposal options when selecting treatment approaches.

Revenue opportunities from treated materials can significantly improve project economics through beneficial reuse applications. Properly treated water-based drilling cuttings may be suitable for construction aggregate, road base material, or soil amendment applications, depending on composition and regulatory approval. Market demand and transportation costs influence the economic viability of these beneficial use options.

Operational Efficiency Improvements

Optimizing treatment system operations reduces processing costs and improves overall project economics. Regular maintenance programs prevent equipment failures and maintain optimal performance levels, while process optimization studies identify opportunities for energy reduction and throughput improvements. Automation systems can enhance operational consistency and reduce labor requirements.

Integration of treatment systems with drilling operations minimizes material handling costs and reduces temporary storage requirements. Real-time monitoring and control systems enable rapid response to changing waste characteristics and maintain consistent treatment performance. These improvements contribute to overall operational efficiency and cost reduction.

FAQ

What are the main differences between water-based and oil-based drilling cuttings?

Water-based drilling cuttings contain lower hydrocarbon concentrations and are generally easier to treat and dispose of compared to oil-based alternatives. They typically have higher moisture content and require different treatment approaches, but offer greater flexibility for beneficial reuse applications and land disposal options.

How long can treated water-based drilling cuttings be stored before disposal?

Storage duration depends on local regulations, treatment effectiveness, and environmental conditions. Properly treated materials can typically be stored for several months under appropriate containment conditions, but operators should consult local regulations and implement monitoring programs to ensure continued compliance throughout the storage period.

What factors influence the selection of treatment technology for water-based drilling cuttings?

Key factors include waste volume and generation rate, moisture content, disposal options, regulatory requirements, and economic considerations. Site-specific conditions such as available space, utilities, and transportation access also influence technology selection. Environmental sensitivity and community concerns may require enhanced treatment performance.

Can water-based drilling cuttings be recycled or reused after treatment?

Yes, properly treated water-based drilling cuttings can often be beneficially reused for construction applications, road building, or agricultural soil amendment, depending on composition and regulatory approval. Successful reuse programs require thorough characterization, appropriate treatment, and compliance with applicable quality standards and environmental regulations.

Table of Contents

- Understanding Water-Based Drilling Cuttings Composition

- Treatment Technologies and Processing Methods

- Regulatory Compliance and Environmental Standards

- Economic Optimization Strategies

-

FAQ

- What are the main differences between water-based and oil-based drilling cuttings?

- How long can treated water-based drilling cuttings be stored before disposal?

- What factors influence the selection of treatment technology for water-based drilling cuttings?

- Can water-based drilling cuttings be recycled or reused after treatment?