gestion des déchets de dragage

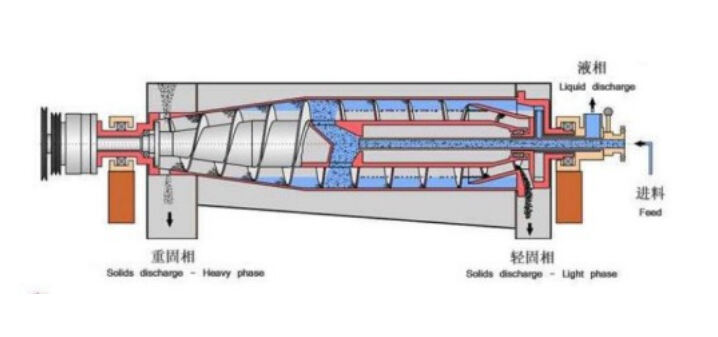

La gestion des déchets de dragage représente un système global conçu pour gérer, traiter et éliminer les matériaux extraits lors des opérations de dragage de manière responsable vis-à-vis de l'environnement. Ce processus sophistiqué implique la collecte, le traitement et l'élimination durable des sédiments, des débris et d'autres matériaux retirés des masses d'eau. Le système utilise des technologies avancées de séparation pour différencier les divers composants du matériel dragué, y compris le sable, la vase, l'argile et la matière organique. La gestion moderne des déchets de dragage intègre des systèmes de surveillance en temps réel qui suivent la composition des matériaux et les niveaux de contamination, garantissant ainsi le respect des réglementations environnementales. La technologie utilise des techniques de déséquation pour réduire le volume de déchets, rendant le transport et l'élimination plus efficaces. De plus, le système met en œuvre des méthodes de traitement innovantes pour neutraliser les contaminants potentiels et préparer les matériaux pour une réutilisation bénéfique lorsque cela est possible. Ces opérations sont soutenues par des systèmes de contrôle automatisés qui optimisent l'ensemble du processus, de la collecte initiale à l'élimination ou au réemploi final. Les applications couvrent la construction maritime, l'entretien des ports, les projets de remédiation environnementale et les initiatives de protection côtière.