matériel de dragage des sédiments fluviaux

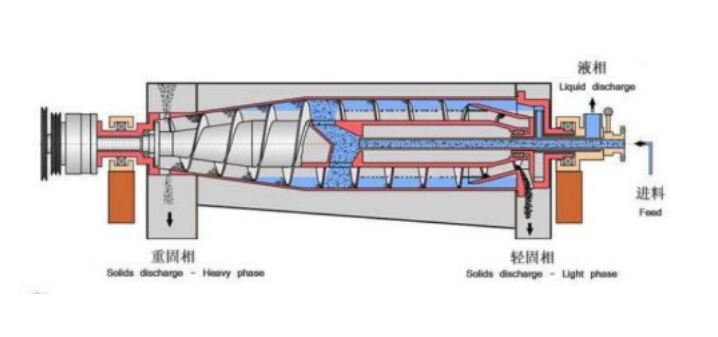

Les équipements de déplacement des sédiments fluviaux représentent une technologie de pointe conçue pour extraire et gérer efficacement les sédiments accumulés dans les cours d'eau, les lits de rivière et les plans d'eau. Cette machinerie spécialisée combine des capacités de dragage puissantes avec des systèmes de filtration avancés pour enlever efficacement de la vase, du sable et des débris tout en maintenant la qualité de l'eau. L'équipement présente généralement des pompes à grande capacité, des systèmes de contrôle précis et des mécanismes de fonctionnement respectueux de l'environnement qui minimisent la perturbation de l'écosystème. Son design modulaire permet une mise en œuvre dans diverses conditions d'eau, des petits ruisseaux aux sections profondes des rivières. La technologie intègre des systèmes de surveillance en temps réel qui optimisent les taux d'extraction des sédiments tout en empêchant le sur-dragage. Ces machines peuvent traiter des centaines de mètres cubes de matériaux par heure, séparant l'eau des sédiments grâce à des systèmes sophistiqués de déséquation. La polyvalence de l'équipement s'étend à la gestion de différents types de sédiments, de la vase fine au sable grossier, ce qui le rend inestimable pour l'entretien des rivières, la prévention des inondations et les projets de restauration environnementale. Les unités modernes incluent souvent des capacités de positionnement GPS et de suivi de profondeur, garantissant un fonctionnement précis et une documentation des zones dégagées.