Oil-based drilling cuttings waste treatment, also known as cuttings non-landing system or drilling cuttings non-landing system, is an indispensable environmental protection treatment equipment in modern drilling operations. The system consists of a n...

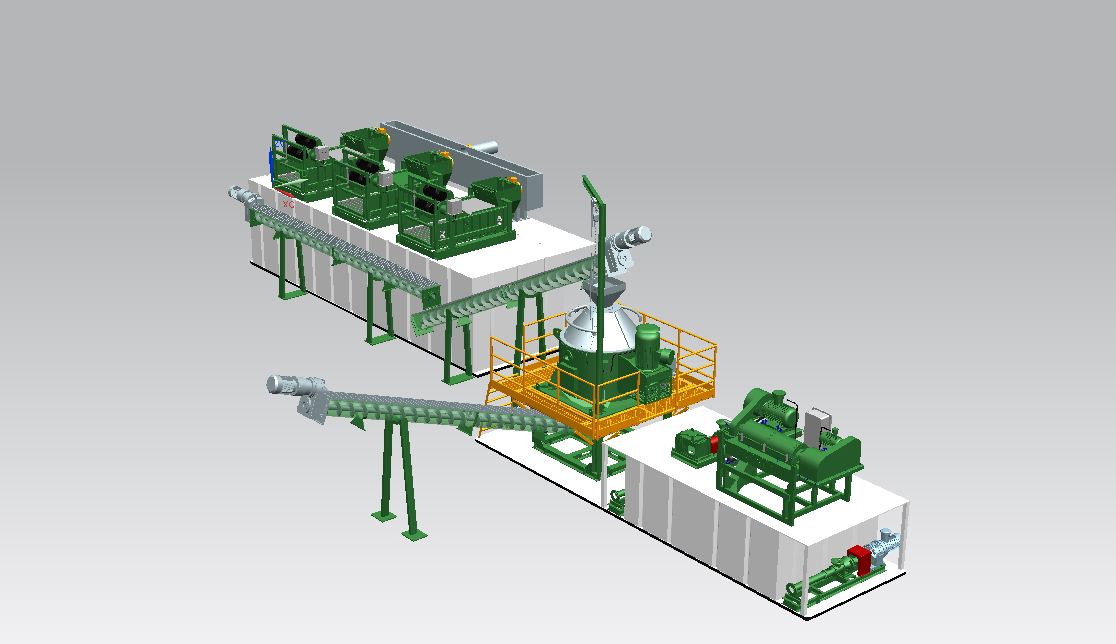

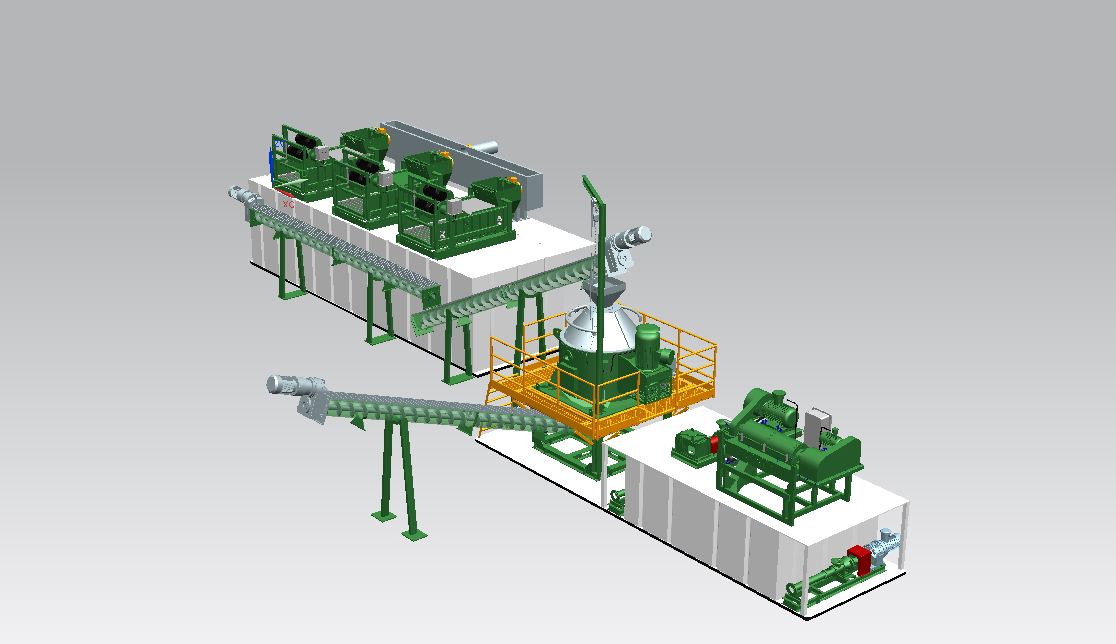

Oil-based drilling cuttings waste treatment, also known as cuttings non-landing system or drilling cuttings non-landing system, is an indispensable environmental protection treatment equipment in modern drilling operations. The system consists of a number of key equipment, including cuttings drying machine, high speed variable frequency centrifuge, skid-mounted integrated tank, liquid slurry pump, agitator, screw conveyor and cuttings box, forming a complete treatment system.

The Core equipment of oil-based drilling cuttings waste treatment:

|

|

| Vertical cuttings dryer | Decanter Centrifuge |

|

|

| Screw Conveyor | Cuttings collection box |

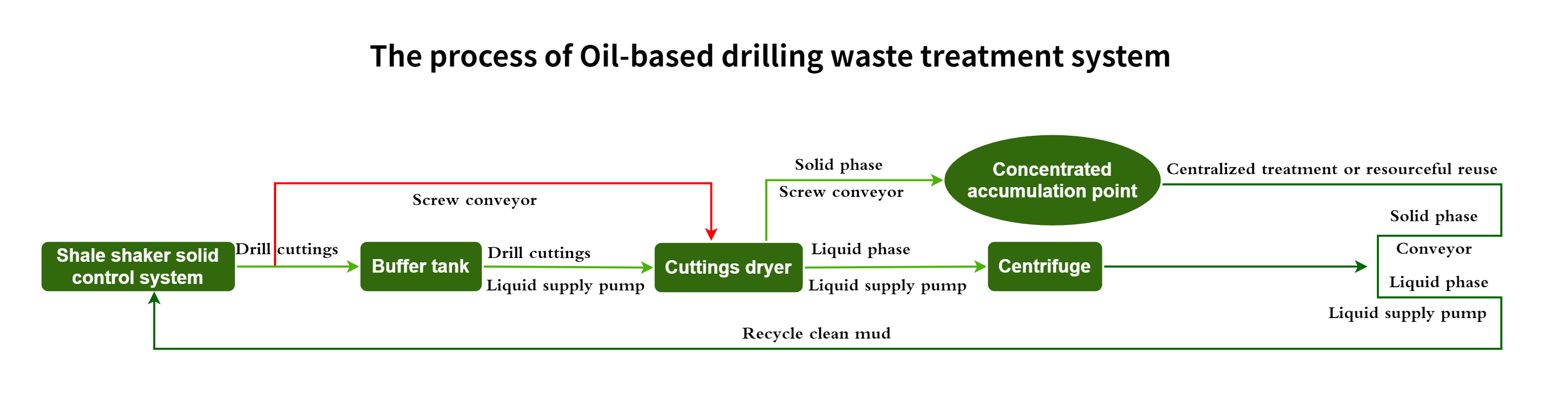

The process of oil-based drilling cuttings waste treatment:

Advantages of Oil-based drilling cuttings waste treatment:

● The efficient continuous feed capability ensures the continuity and efficiency of drilling operations.

● Minimizes fluid content in the cuttings.

● The system adopts PLC integrated control technology, the operation interface is friendly, safe and reliable.

● Modular design, easy to move, reduce transportation costs.

Application range of Oil-based drilling cuttings waste treatment:

The application range of oil-based mud non-landing technology is very wide, covering oil, natural gas, shale gas, coal bed methane, geothermal energy, mineral exploration, drilling in environmentally sensitive areas, offshore drilling and unconventional energy development. Its core advantages are environmental protection and efficient use of resources, which can effectively reduce the environmental pollution of drilling operations, while reducing the cost of waste pulp treatment, in line with the trend of green development of modern drilling industry.

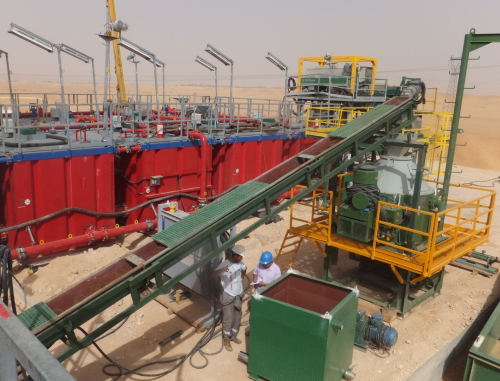

Project Case

|

|

Site of the oil-based drill cuttings processing project in Algeria