drill cuttings disposal

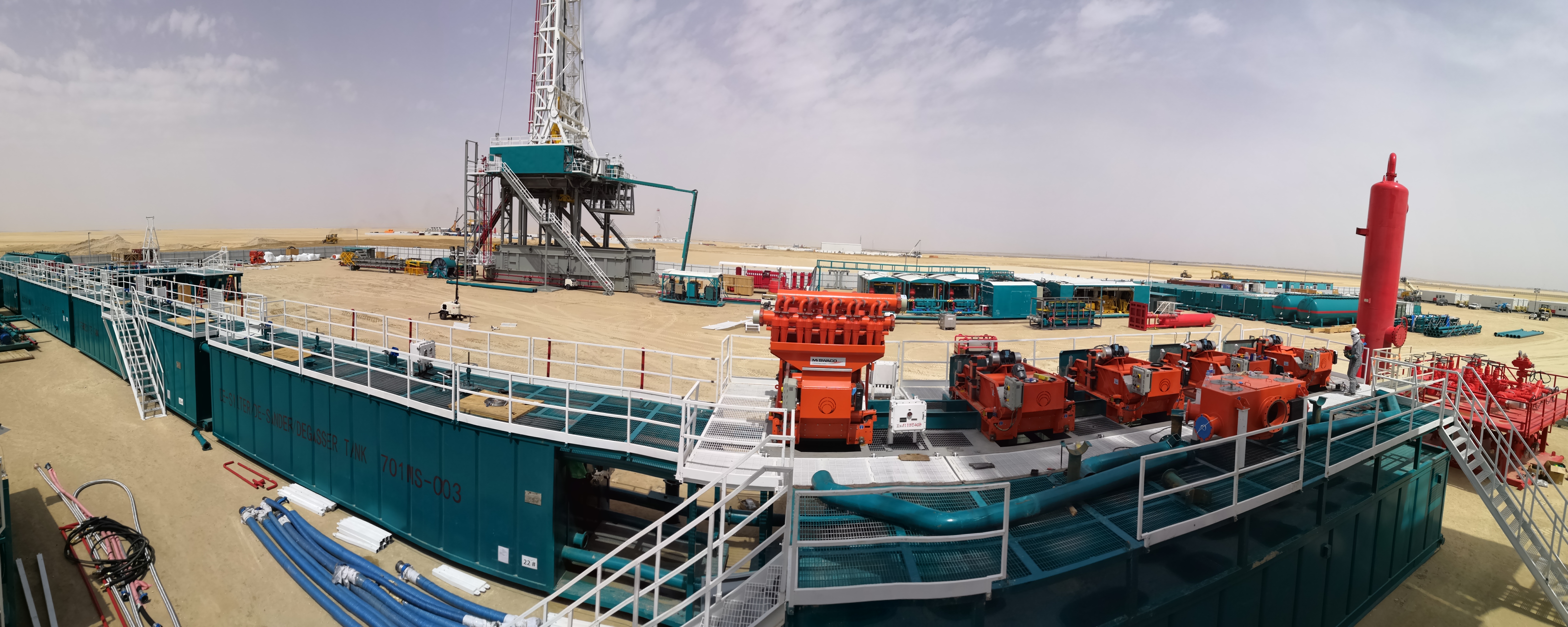

Drill cuttings disposal is a critical environmental management process in the oil and gas industry, focusing on the safe and efficient handling of waste materials generated during drilling operations. This comprehensive waste management system involves multiple stages of treatment and disposal, ensuring compliance with environmental regulations while maintaining operational efficiency. The process begins with the separation of drill cuttings from drilling fluids, followed by various treatment methods including thermal treatment, stabilization, and chemical processing. Modern drill cuttings disposal systems incorporate advanced technologies such as thermal desorption units, centrifugal separators, and automated handling systems to maximize recovery and minimize environmental impact. These systems can process large volumes of drill cuttings, typically handling hundreds of tons per day, while recovering valuable drilling fluids for reuse. The technology has evolved to include real-time monitoring capabilities, ensuring optimal performance and compliance with environmental standards. Applications extend across offshore and onshore drilling operations, with specialized solutions for different geological conditions and regulatory requirements.