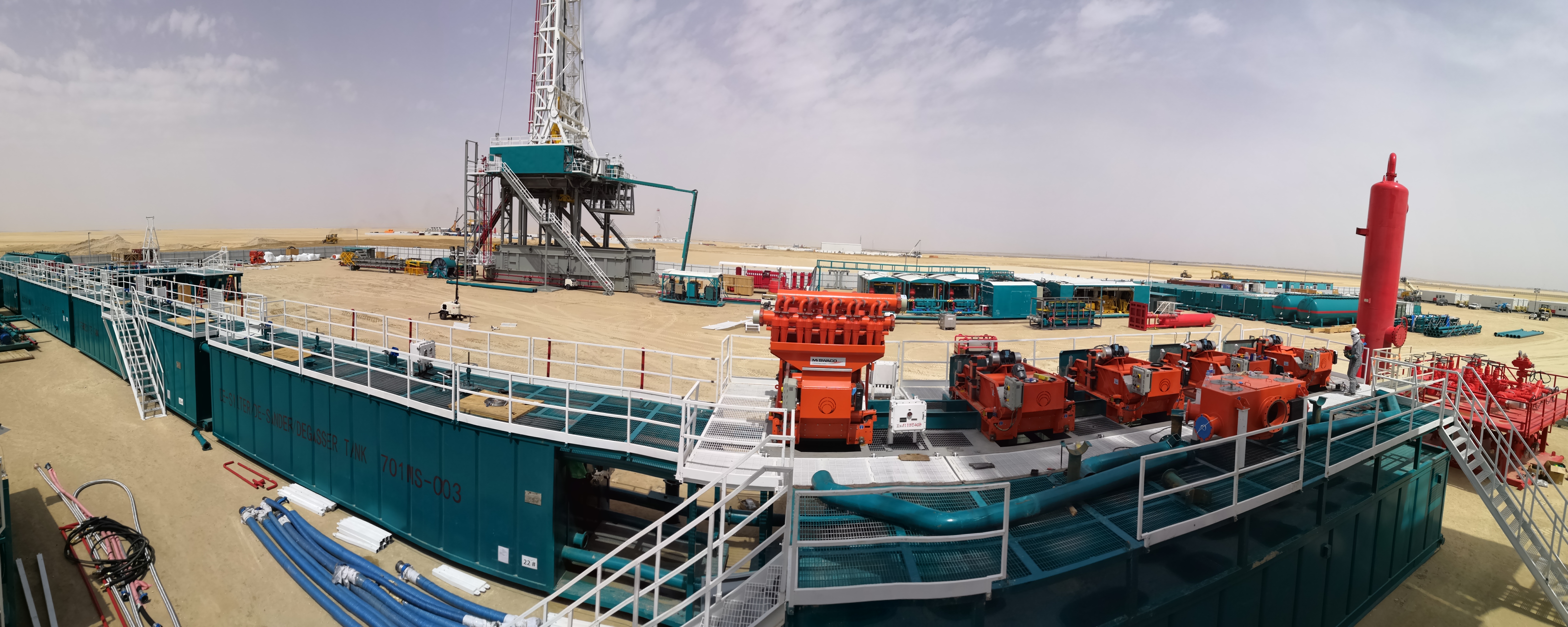

horizontal directional drilling mud treatment

Horizontal directional drilling mud treatment is an essential process in modern drilling operations that focuses on the purification, recycling, and maintenance of drilling fluids. This sophisticated system comprises various components working in harmony to ensure optimal drilling performance. The treatment process begins with the separation of drill cuttings from the mud using shale shakers, which act as the primary screening device. Following initial separation, the mud undergoes further processing through hydrocyclones and centrifuges to remove finer particles and maintain proper mud properties. The system continuously monitors and adjusts vital parameters such as viscosity, density, and chemical composition to ensure the mud performs its critical functions effectively. These functions include cooling and lubricating the drill bit, carrying cuttings to the surface, maintaining wellbore stability, and preventing formation damage. Advanced sensors and automated control systems enable real-time adjustments to mud properties, ensuring optimal drilling conditions throughout the operation. The treated mud is then recirculated back into the drilling system, creating an efficient closed-loop process that minimizes waste and environmental impact while maximizing drilling efficiency.