mud cleaning system for drilling

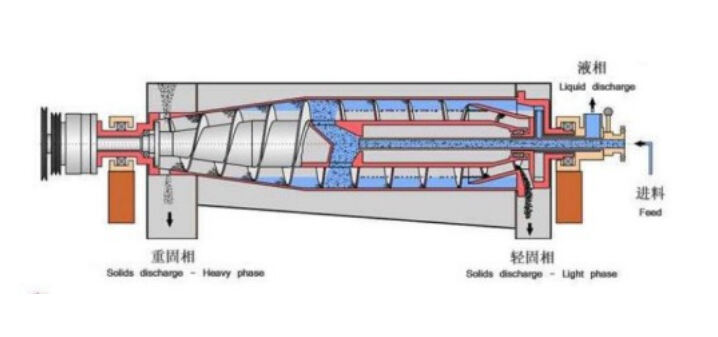

A mud cleaning system for drilling is an essential component of modern drilling operations that effectively separates and removes unwanted solids from drilling fluids. This sophisticated system comprises multiple stages of separation equipment, including shale shakers, desanders, desilters, and centrifuges, working in harmony to maintain optimal drilling fluid properties. The primary function involves processing used drilling mud to remove various sizes of solid particles, from large cuttings to microscopic particles, ensuring the mud can be recirculated back into the drilling process. The system utilizes advanced mechanical and hydraulic principles to achieve maximum efficiency in solid-liquid separation. Modern mud cleaning systems incorporate automated controls and monitoring systems that provide real-time data on fluid properties and separation efficiency. These systems are designed to handle high-volume processing while maintaining consistent performance under varying drilling conditions. The technology is particularly valuable in deep drilling operations where maintaining proper mud properties is crucial for well stability and drilling performance. The system's ability to clean and recycle drilling fluids significantly reduces waste disposal requirements and operational costs while promoting environmental sustainability.