Sustav za hlađenje bušaćeg blata. Uz rastuću potražnju za naftom i plinom, potrebu za kontinuiranim razvojem bušaćih resursa i potrebama nacionalnih energetskih strategija, razvijena su visoko kompleksna bušenja poput bušotina na visoke temperature, dubokih bušotina i različitih...

Hlađenje borbene šljunke Sustav.

Uz rastuću potražnju za naftom i plinom, potrebu za kontinuiranim razvojem bušaćih resursa i potrebama nacionalnih energetskih strategija, razvijena su visoko kompleksna bušenja poput bušotina na visoke temperature, dubokih bušotina i različitih složenih formacija. Stoga se broj bušotina na visoke temperature i dubokih bušotina povećava, što je također neizbježan trend u razvoju tehnologije bušenja nafte i plina. Bлатo na visokoj temperaturi tijekom procesa bušenja može dovesti do oštećenja uzrokovanih visokom temperaturom, što se obično očituje sljedećim negativnim učincima:

● Točnost mjernih instrumenata tijekom bušenja na dnu bušotine bit će neprecizna, a podaci se ne mogu normalno prenositi i primati;

● Plastična viskoznost bušaćeg fluida će se smanjiti, a gustoća također će opasti, što rezultira lošim performansama nošenja stijene i smanjenom prijenosnom snagom. Stoga se smanjuje učinkovitost tretmanskih agenata, što povećava troškove mulja;

● Također može povećati poteškoće u upravljanju muljem, jer se neki tretmani lako razgrađuju na visokim temperaturama;

● Mehanička svojstva bušaćih uređaja, posebno vrhova za bušenje, alata za bušenje, cijevi i drugih aktuatora koji su u direktnom kontaktu, kao i brzinska svojstva i vijek trajanja brtvila su smanjeni;

● Za uljni mulj, visokotemperaturni mulj povećava rizik od sigurnosnih faktora u radu;

Glavna svrha sustava hlađenja mulja je kontrolirati i prilagoditi svojstva mulja, odnosno kontrolirati temperaturu mulja.

|

|

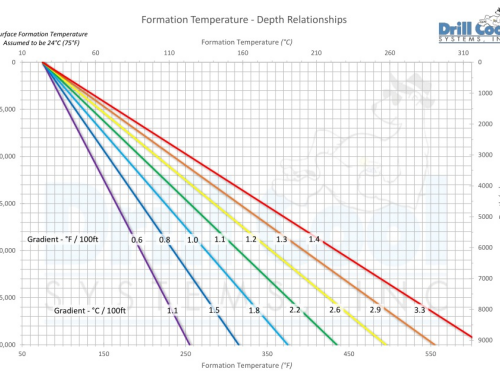

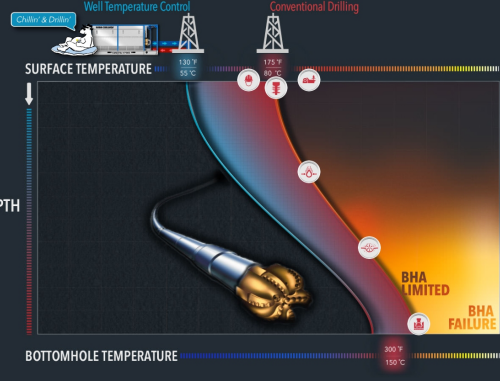

| Dijagram odnosa između dubine bušotine, nagiba i temperature bušaćeg fluida | Dijagram promjene temperature mulja prije i nakon hlađenja |

Opis sheme hlađenja blata za vrtanje

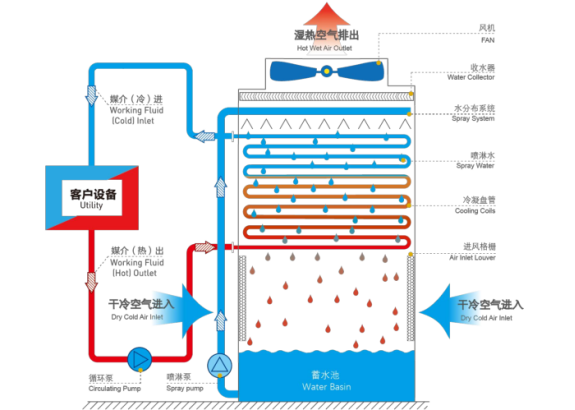

Sustav hlađenja blata za vrtanje je ključna oprema u operacijama naftnog vrtanja, koji se glavnose koristi za kontrolu temperature vrtinskog fluida kako bi se osigurala sigurnost i učinkovitost procesa vrtanja. U visokotemperaturnim slojevima ili pri dubinskom vrtanju, temperatura vrtinskog fluida značajno će narasti zbog dugotrajne cirkulacije i prijema topline od sloja, što može dovesti do oštećenja performansi vrtinskog fluida, oštećenja opreme i čak nezgoda ispod površine. Sustav hlađenja vrtinskog fluida koristi učinkovitu tehnologiju razmjene topline kako bi hladio visokotemperaturni vrtinski fluid na pravu temperaturu, održavajući njegovu stabilnost dok pruža duži životopis opreme. Sustav se obično sastoji od uređaja za hlađenje, cirkulacijskog pumpe, radijatora, upravljačkog sustava itd., a može se odabrati vodenim hlađenjem, zrakom hlađenje ili mješovitim hlađenjem prema specifičnim potrebama.

|

|

Proces hlađenja riječnog blata:

● Način rada sustava za hlađenje riječnog fluida temelji se na razmjeni topline:

● Nakon što visoko temperaturno riječno blato vratiti s šachta, ulazi u jedinicu za hlađenje putem cirkulacijskog čerpnje.

● U jedinici za hlađenje, riječno blato razmjenjuje toplinu s hladnom tvari (poput vode ili zraka), a temperatura se smanjuje.

● Hladno riječno blato ponovno se ubacuje u šacht i nastavlja se reciklirati.

● Nakon što hladna tvar apsorbira toplinu, toplina se ispušta u okoliš kroz radijator ili hlađajuću kulu.

Prednosti sustava za hlađenje riječnog blata

● Poboljšanje učinkovitosti bora: Održavanje stabilnog performansi riječnog fluida i smanjenje podzemnih nezgoda.

● Prodluživanje života opreme: smanjenje štete od visoke temperature na opremu.

● Zaštita okoliša i ušteda energije: smanjenje otpadnih resursa putem recikliranja riječnog fluida.

● Jača prilagodljivost: odgovara za rad u visokotemperaturnim formacijama, dubokim i ultra-dubokim bunarima.

Područje primjene sustava hlađenja borbne šlamije:

● Bureanje u visokotemperaturnim formacijama: na primjer, geotermalnim bunarima ili visokotemperaturnim naftnim i plinovima.

Duboko i ultra-duboko bureanje: s povećanjem dubine bunara, temperature formacije rastu i potrebni su hlađeni sustavi.

● Rad s visokogustim burenim fluidom: visokogusti bureći fluid je više podložan prihvaćanju topline i treba ga hladiti kako bi se održao njegov performans.