continuous oil clarification systems

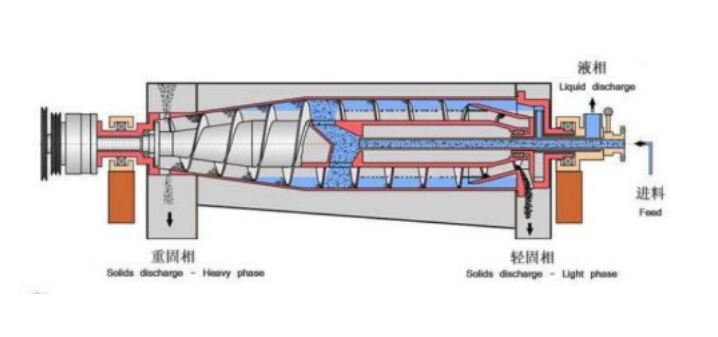

Continuous oil clarification systems represent a groundbreaking advancement in industrial oil processing technology. These sophisticated systems operate through a seamless process that removes contaminants, water, and particulate matter from various types of oils, ensuring consistent quality output. The system employs multiple stages of filtration and separation, including centrifugal force, coalescence, and advanced membrane technology, to achieve optimal oil purification. The primary function involves the continuous removal of impurities while maintaining uninterrupted operation, significantly reducing downtime and increasing productivity. These systems are equipped with automated monitoring capabilities that adjust processing parameters in real-time, ensuring maximum efficiency and minimal waste. Applications span across numerous industries, from food processing and manufacturing to power generation and marine operations. The technology incorporates innovative features such as self-cleaning mechanisms, intelligent flow control, and precision filtration elements that can handle various oil viscosities and contamination levels. Modern continuous oil clarification systems also integrate digital controls and remote monitoring capabilities, allowing operators to maintain precise control over the purification process while collecting valuable operational data for analysis and optimization.