custom biofuel separation solutions

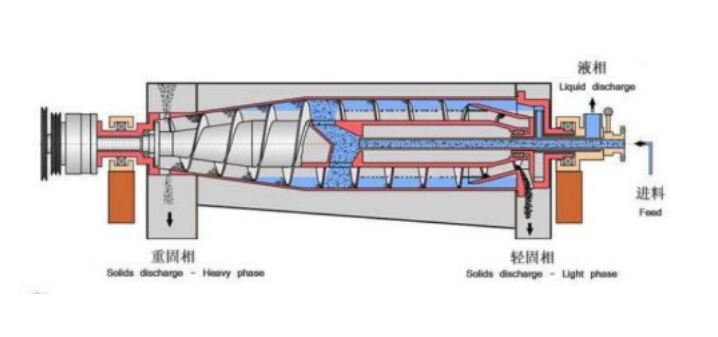

Custom biofuel separation solutions represent cutting-edge technology designed to efficiently separate and purify various types of biofuels from their raw materials and byproducts. These advanced systems utilize multiple separation techniques, including membrane filtration, centrifugation, and molecular distillation, to achieve optimal results. The solutions are engineered to handle diverse feedstocks, from agricultural waste to algae-based materials, ensuring maximum yield and product quality. The technology incorporates smart automation systems that monitor and adjust separation parameters in real-time, maintaining consistent performance throughout the process. These solutions feature modular designs that can be customized to specific production requirements, ranging from small-scale laboratory operations to large industrial facilities. The systems are equipped with advanced sensors and control mechanisms that optimize energy consumption while maintaining high separation efficiency. Applications span across various industries, including biodiesel production, bioethanol refinement, and renewable aviation fuel manufacturing. The solutions also include specialized cleaning systems that minimize maintenance downtime and extend equipment lifecycle.