industrial centrifuge for oil extraction

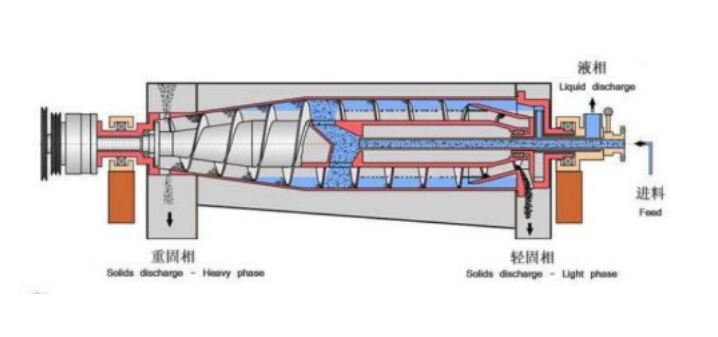

Industrial centrifuges for oil extraction represent a cornerstone technology in modern processing facilities, utilizing centrifugal force to separate oil from various raw materials efficiently. These sophisticated machines operate on the principle of density difference, spinning at high speeds to separate lighter oil components from heavier substances. The equipment features advanced control systems that maintain optimal separation conditions throughout the extraction process, ensuring maximum yield and product quality. The centrifuge's design incorporates precision-engineered components, including a rotating bowl, conveyor, and automated feed system, working in harmony to achieve continuous separation. These machines handle diverse feedstock materials, from seeds and nuts to fruit pulp, making them versatile solutions for different industrial applications. The technology employs variable speed control, allowing operators to adjust processing parameters based on specific material requirements. Modern industrial centrifuges also integrate safety features such as vibration monitoring systems and emergency shutdown capabilities, ensuring reliable operation in demanding industrial environments. The equipment's capacity can range from processing several hundred kilograms to multiple tons per hour, catering to various production scale requirements.