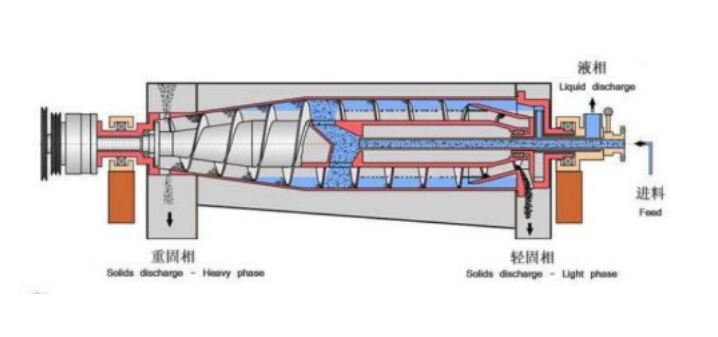

highyield oil recovery centrifuge

The highyield oil recovery centrifuge represents a cutting-edge solution in industrial oil processing and recovery operations. This sophisticated piece of equipment utilizes advanced centrifugal force technology to efficiently separate oil from various mixtures and emulsions, achieving exceptional recovery rates of up to 99%. The machine operates through a precisely controlled rotating mechanism that generates powerful centrifugal forces, effectively separating substances based on their different densities. Its innovative design incorporates multiple separation zones and advanced automation systems, allowing for continuous operation while maintaining consistent performance levels. The centrifuge features adjustable speed controls, specialized bowl designs, and automated cleaning systems that minimize maintenance requirements while maximizing operational efficiency. This versatile equipment finds extensive applications across numerous industries, including food processing, industrial manufacturing, waste oil recovery, and environmental protection. The system's ability to handle various types of oil-containing materials, from industrial wastewater to food processing residues, makes it an invaluable tool in modern industrial operations. Its robust construction ensures reliable performance under demanding conditions, while its advanced control systems enable precise adjustment of separation parameters to meet specific requirements. The highyield oil recovery centrifuge also incorporates safety features such as vibration monitoring and emergency shutdown systems, ensuring safe and reliable operation in all circumstances.