automated centrifuge control for oil processing

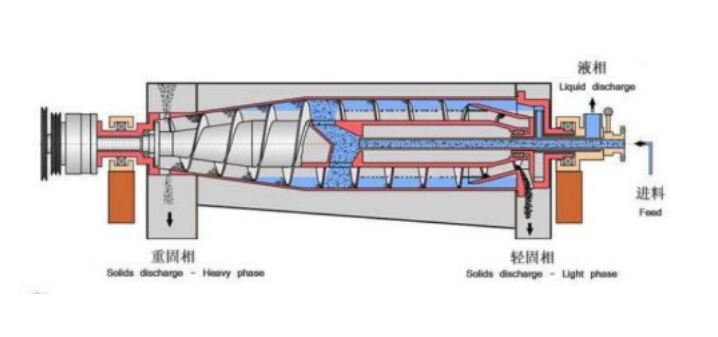

Automated centrifuge control for oil processing represents a cutting-edge solution in the petroleum industry, combining precision engineering with advanced automation technology. This sophisticated system manages the entire centrifugation process, from initial feed to final separation, ensuring optimal oil purification and component separation. The system incorporates real-time monitoring capabilities, adaptive control algorithms, and intelligent feedback mechanisms to maintain consistent performance across varying operating conditions. Key functions include automated speed regulation, temperature control, flow rate optimization, and precise separation of oil components based on density differences. The technology features advanced sensors that continuously monitor critical parameters such as rotation speed, temperature, pressure, and separation efficiency. These measurements enable automatic adjustments to maintain optimal processing conditions while minimizing energy consumption. The system's applications span across various sectors of the oil industry, including crude oil processing, lubricant manufacturing, and waste oil recovery. Its versatility allows for processing different types of oils with varying viscosities and contamination levels, making it an essential tool in modern oil refineries and processing facilities.