pharmaceutical centrifugation systems

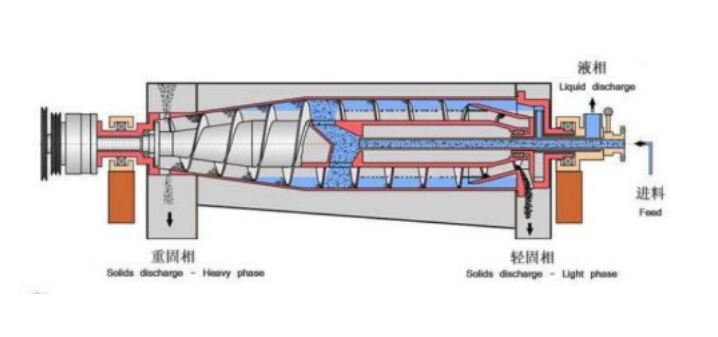

Pharmaceutical centrifugation systems represent essential equipment in modern pharmaceutical manufacturing and research processes. These sophisticated systems employ centrifugal force to separate particles, molecules, and cellular components based on their density differences. The technology operates by rotating samples at high speeds, creating a powerful centrifugal force that effectively separates components within a mixture. Modern pharmaceutical centrifugation systems come equipped with advanced features including precise temperature control, programmable acceleration and deceleration rates, and automated operation sequences. These systems are available in various configurations, from benchtop models for small-scale laboratory work to large industrial units for commercial production. The applications span across multiple pharmaceutical processes, including drug development, quality control testing, and production of biologics. These systems excel in tasks such as cell harvesting, protein purification, particle size separation, and the isolation of specific compounds. The technology incorporates safety features such as imbalance detection, emergency shutdown systems, and sealed rotors to prevent contamination. Additionally, modern systems often include digital interfaces for process monitoring and data logging, ensuring compliance with regulatory requirements and maintaining consistent documentation of separation processes.