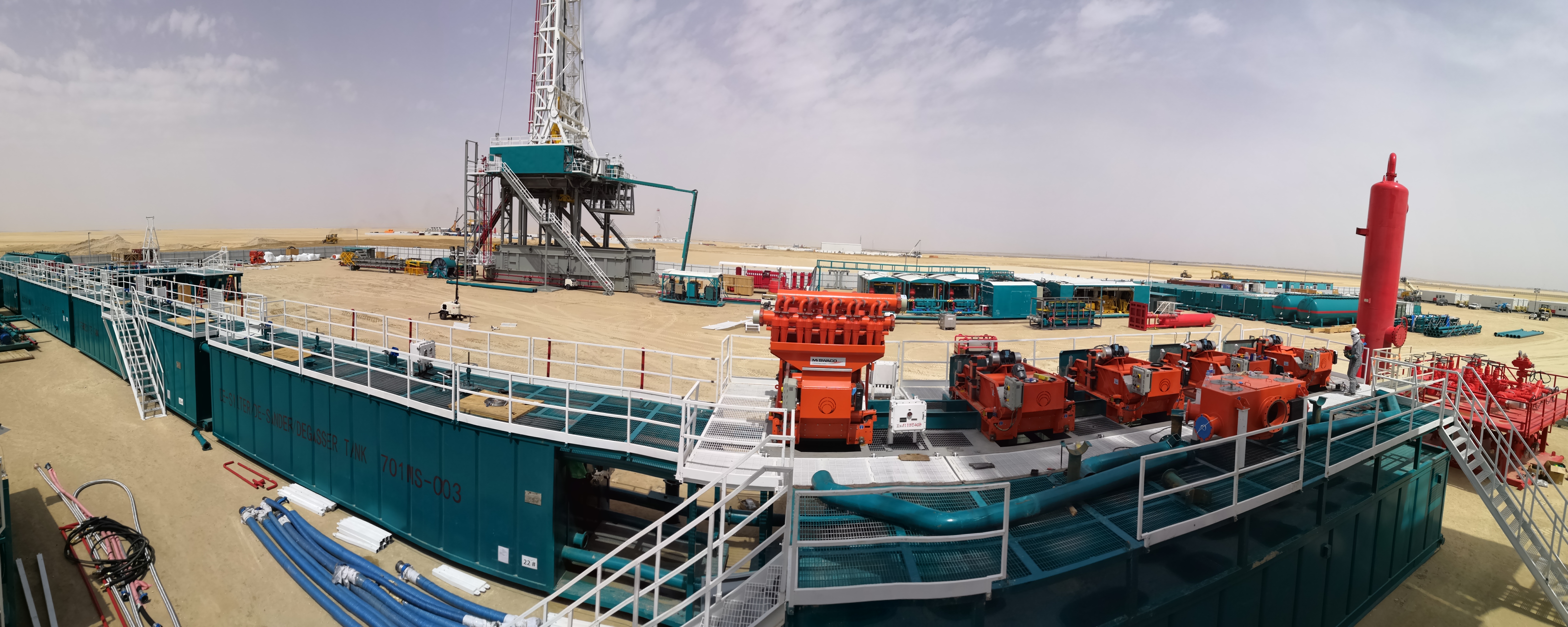

mud cooling

Mud cooling systems represent a crucial component in drilling operations, designed to maintain optimal temperature control of drilling fluids. These sophisticated systems employ advanced heat exchange technology to effectively reduce the temperature of drilling mud, which is essential for maintaining drilling efficiency and protecting downhole equipment. The system typically consists of heat exchangers, cooling towers, circulation pumps, and temperature monitoring devices that work in concert to achieve precise thermal management. By implementing efficient cooling mechanisms, these systems can handle high-volume mud flow rates while maintaining consistent temperature control, crucial for deep drilling operations where heat buildup can be significant. The technology incorporates automated control systems that continuously monitor and adjust cooling parameters, ensuring optimal performance under varying operational conditions. Modern mud cooling systems are designed with energy efficiency in mind, utilizing advanced materials and smart control algorithms to minimize power consumption while maximizing cooling effectiveness. These systems are particularly valuable in high-temperature drilling environments, geothermal operations, and deep-water drilling projects where maintaining proper mud temperature is critical for successful operations.