oilbased drill cuttings treatment

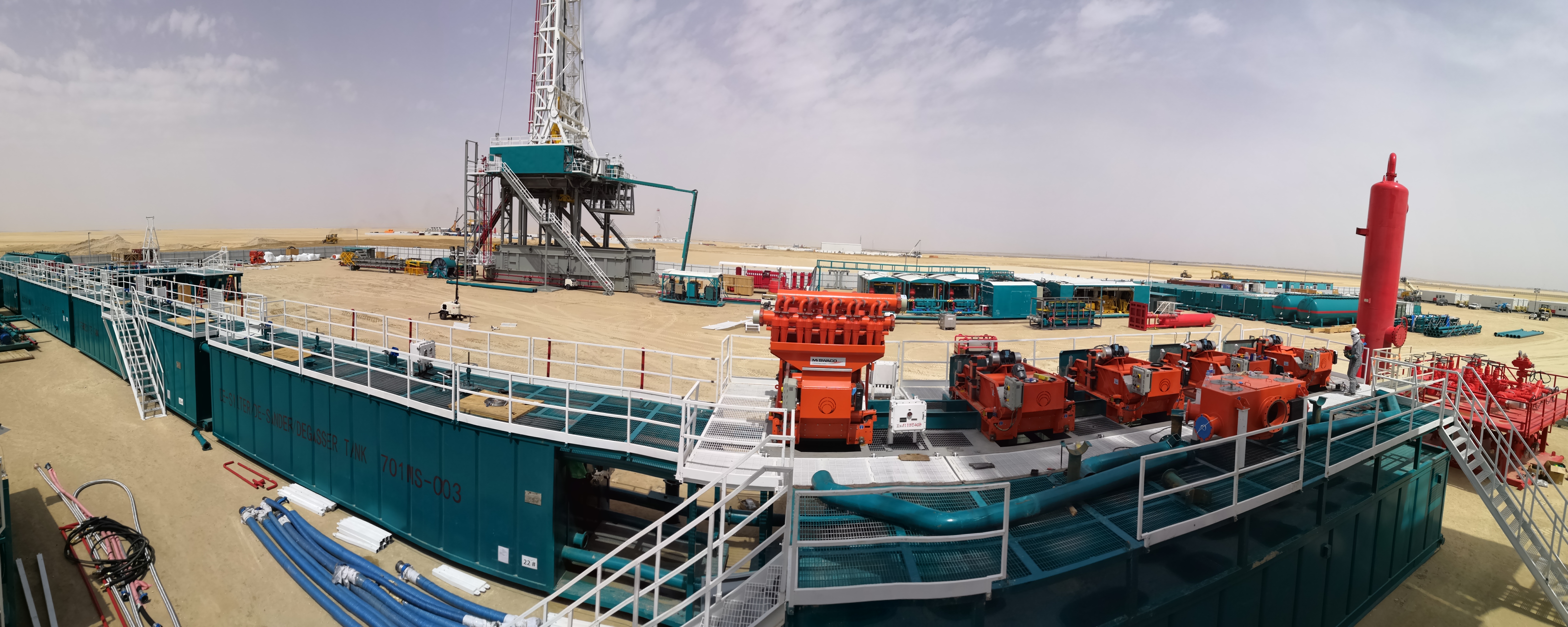

Oil-based drill cuttings treatment is a crucial environmental management process in the oil and gas industry that focuses on separating and recovering valuable components from drilling waste. This advanced treatment system employs multiple technologies including thermal desorption, centrifugation, and chemical treatment to process drill cuttings contaminated with oil-based drilling fluids. The process begins with the mechanical separation of larger particles, followed by thermal treatment that removes hydrocarbons from the drill cuttings. The system can process various types of oil-based mud cuttings, achieving recovery rates of up to 99% for oil and producing clean, reusable solids. The treatment plant typically consists of feeding units, thermal processing chambers, condensation systems, and material handling equipment. Modern facilities are designed with automated control systems that monitor and adjust processing parameters in real-time, ensuring optimal treatment efficiency. The recovered oil can be recycled back into the drilling fluid system, while the treated solids can be safely disposed of or used in construction applications. This technology has become increasingly important as environmental regulations become stricter and companies seek sustainable waste management solutions.