oilbased mud solidliquid separation system

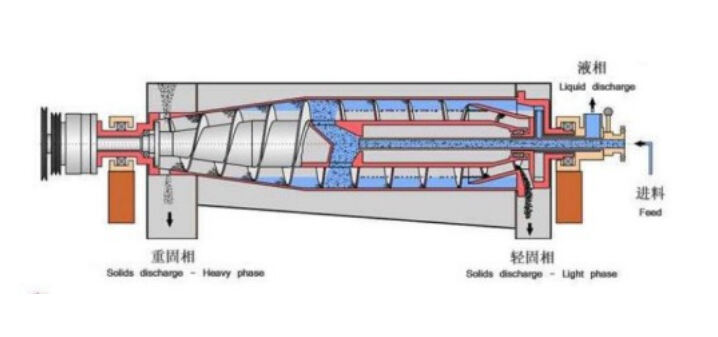

The oilbased mud solidliquid separation system represents a cutting-edge solution for drilling operations, designed to efficiently separate solid particles from oil-based drilling fluids. This advanced system incorporates multiple stages of separation technology, including shale shakers, hydrocyclones, and centrifuges, working in harmony to achieve optimal mud cleaning results. The system's primary function is to remove unwanted solids from drilling fluid while preserving its valuable components, ensuring the mud can be recycled and reused effectively. The technology features sophisticated control systems that automatically adjust separation parameters based on real-time monitoring of mud properties, particle size distribution, and flow rates. In practical applications, the system proves invaluable in both onshore and offshore drilling operations, particularly in challenging environments where maintaining mud quality is crucial. The system's modular design allows for easy installation and maintenance, while its high-efficiency separation capabilities significantly reduce waste volume and operating costs. Advanced sensing technology and automated controls ensure consistent performance while minimizing operator intervention, making it an essential component in modern drilling operations.