« Les coûts mensuels d'électricité représentent 30 % à 35 % des frais de fonctionnement des équipements » — c'est un défi courant pour de nombreuses sociétés de forage utilisant des équipements de contrôle des solides. Les systèmes traditionnels tombent souvent dans le piège de la « forte consommation d'énergie, faible rendement » en raison de moteurs peu efficaces (principalement de classe 2 d'efficacité) et d'une mauvaise adéquation du système. Alors, combien peut-on réellement économiser avec des équipements économes en énergie ? Black Rhino Industrial Co., Ltd., s'appuyant sur des données provenant de plus de 200 projets réels, vous aide à calculer l'ensemble des coûts.

Examinons d'abord la comparaison principale de la consommation d'énergie : les équipements traditionnels de contrôle des solides (prenant comme exemple un système avec une capacité de traitement de 50 m³/h) utilisent des moteurs asynchrones ordinaires, et la consommation énergétique globale du système est d'environ 45 kW·h/heure.

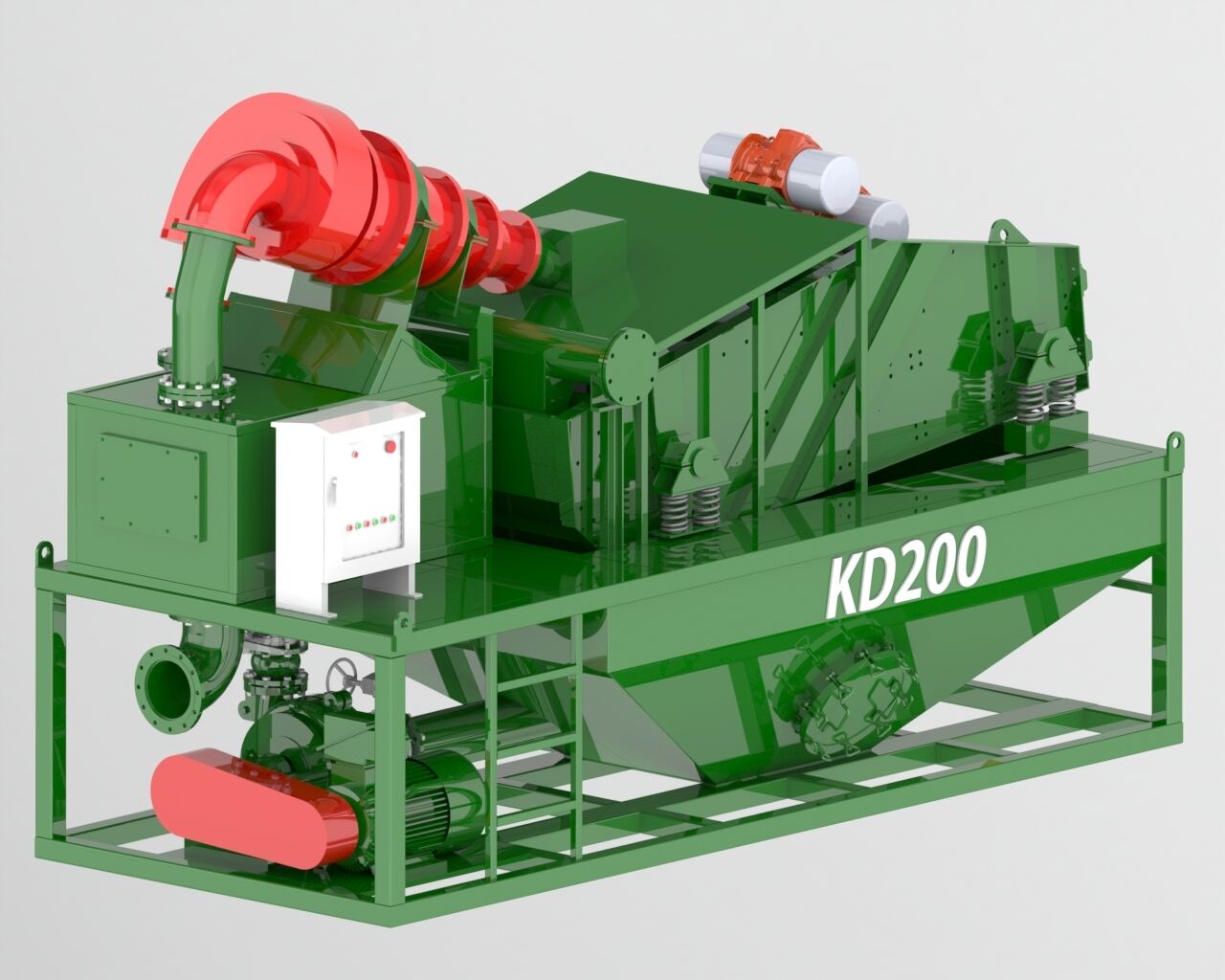

En revanche, les équipements économes en énergie de Black Rhino Industrial sont dotés d'un moteur à aimant permanent à trois étages, à fréquence variable et à haute efficacité énergétique, combiné à une technologie de vibreur économe en énergie conforme aux normes industrielles, réduisant la consommation d'énergie à 30 kW·h/heure, soit une diminution de 33,3 %.

Sur la base d'une unité fonctionnant 18 heures par jour (la durée de fonctionnement conventionnelle dans l'industrie du forage) et d'un prix industriel de l'électricité de 0,75 CNY/kW·h, la facture mensuelle d'électricité pour les équipements traditionnels s'élève à environ 18 225 CNY, tandis que les équipements économes en énergie coûtent seulement 12 150 CNY, permettant d'économiser plus de 6 000 CNY par mois sur les coûts d'électricité.

Coûts de maintenance et de temps d'arrêt : Les équipements traditionnels, fonctionnant en charge élevée, nécessitent le remplacement des pièces d'usure telles que les tamis vibrants et les buses des désableurs 1 à 2 fois par mois. Le coût par maintenance s'élève à environ 3 000 à 5 000 ¥, et chaque opération de maintenance requiert 4 à 6 heures d'indisponibilité. Sur la base d'un chiffre d'affaires journalier de forage de 15 000 ¥, la perte par incident d'indisponibilité est d'environ 3 000 à 3 750 ¥. L'équipement économe en énergie Black Rhino, doté d'un système intelligent de réglage de charge, adapte automatiquement la puissance en fonction de la concentration de boue. L'usure des composants est réduite de 40 % à 50 %, la fréquence de maintenance mensuelle tombe à 0,5 fois, permettant d'économiser plus de 20 000 ¥ par an en coûts de maintenance, tout en réduisant les pertes dues aux temps d'arrêt d'environ 18 000 ¥. À long terme

Avantages complets : un projet de champ gazier de taille moyenne utilisait précédemment deux unités traditionnelles de contrôle des solides de 50 m³/h, avec un coût énergétique annuel total de 594 000 ¥. Après le passage aux équipements économes en énergie de Black Rhino, le coût annuel d'électricité est passé à 396 000 ¥. Grâce à un système de base de récupération de chaleur fatale (couramment utilisé dans l'industrie), il est également possible de couvrir 30 % de la demande locale en eau chaude, réalisant ainsi une économie supplémentaire de 30 000 ¥ par an sur les coûts énergétiques. Sur la base d'une durée de vie typique de l'équipement de 8 ans, les économies cumulées dépassent 178 000 ¥, ce qui suffit à compenser la différence initiale d'achat (l'écart de coût entre les unités économes en énergie et les unités traditionnelles se situant généralement entre 100 000 ¥ et 150 000 ¥).

Il convient de noter que les améliorations énergétiques peuvent également être éligibles à des incitations politiques. Selon le Guide national pour l'application des technologies industrielles d'économie d'énergie, les entreprises achetant des équipements industriels dont l'efficacité énergétique est de niveau 2 ou supérieur peuvent demander des subventions représentant 5 % à 10 % de l'investissement dans l'équipement (le pourcentage exact dépend de la réglementation locale). Par exemple, une entreprise de forage en Chine du Nord a acheté un équipement de contrôle des solides à économie d'énergie et a reçu avec succès une subvention de 8 %, réduisant ainsi l'investissement initial. Les produits économes en énergie de Black Rhino répondent tous aux normes nationales d'efficacité énergétique de niveau 2+ et peuvent aider les entreprises à préparer les documents nécessaires à la demande.

Si une forte consommation d'énergie pèse sur vos coûts, Black Rhino Industrial propose un service gratuit de diagnostic de la consommation énergétique : des ingénieurs mesurent sur site les paramètres de fonctionnement des équipements et calculent précisément le potentiel d'économie d'énergie en fonction des conditions réelles de travail. Parmi les clients passés à des équipements économes en énergie, 80 % ont réalisé une réduction des coûts d'exploitation de 25 % à 30 %, garantissant ainsi une utilisation efficace de chaque kilowattheure.