“Monthly electricity costs account for 30%–35% of equipment operating expenses” — this is a common challenge for many drilling companies using solids control equipment. Traditional systems often fall into the “high energy consumption, low output” trap due to low-efficiency motors (mostly Level 2 efficiency) and poor system matching. So how much can energy-saving equipment actually save? Black Rhino Industrial Co., Ltd., drawing on data from over 200 real projects, helps you calculate the full cost picture.

Let's first look at the core energy consumption comparison: Traditional solids control equipment (taking a system with a processing capacity of 50 m³/h as an example) uses ordinary asynchronous motors, and the system's overall energy consumption is approximately 45 kW·h/hour.

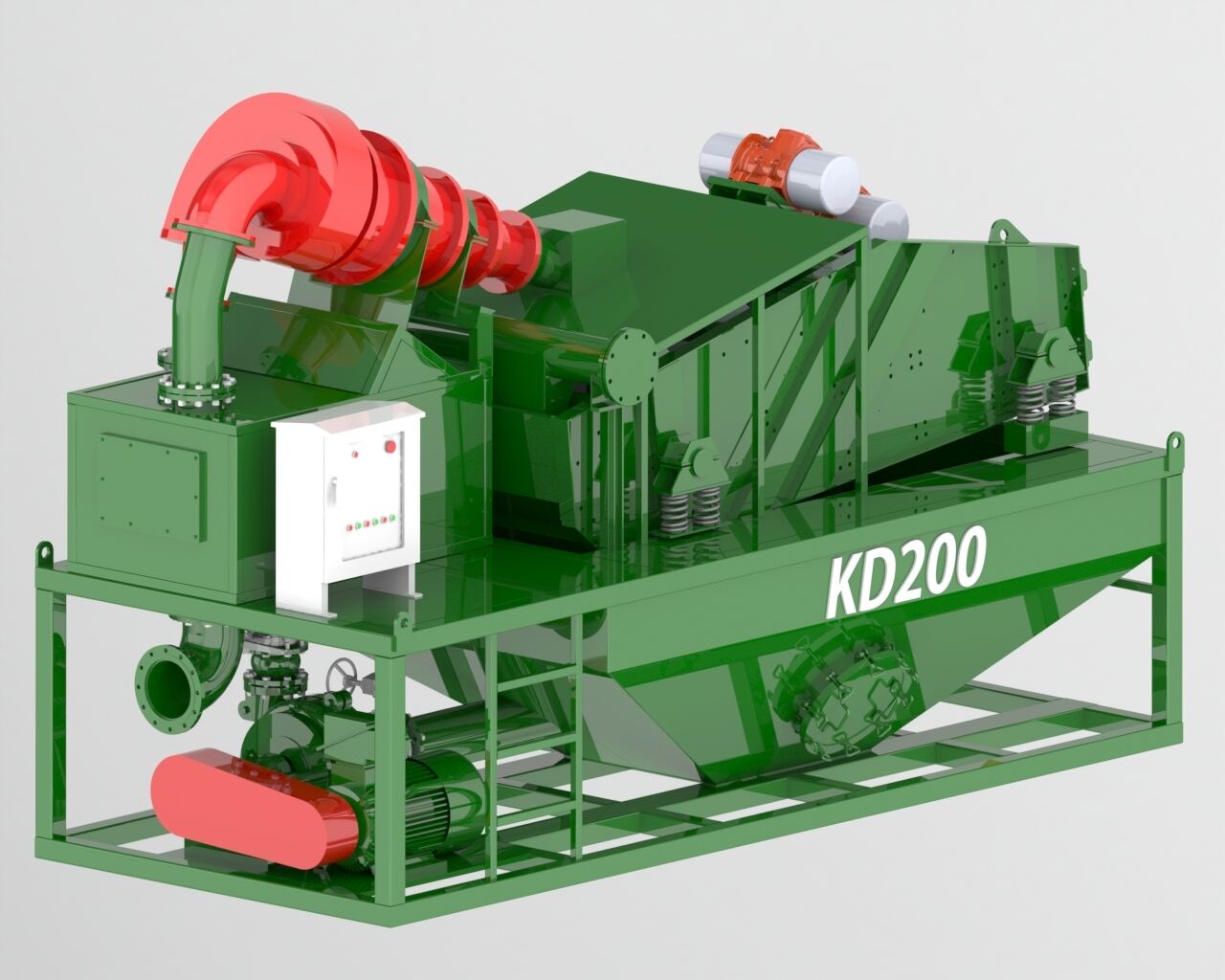

In contrast, Black Rhino Industrial's energy-saving equipment is equipped with a three-stage energy-efficient variable-frequency permanent magnet motor, combined with industry-standard energy-saving vibrator technology, reducing energy consumption to 30 kW·h/hour, a reduction of 33.3%.

Based on a single unit operating 18 hours a day (the conventional operating time in the drilling industry) and an industrial electricity price of 0.75 RMB/kW·h, the monthly electricity bill for traditional equipment is approximately 18,225 RMB, while the energy-saving equipment only costs 12,150 RMB, saving over 6,000 RMB in electricity costs per month.

Maintenance and Downtime Costs: Traditional equipment, operating under high load, requires replacement of wear parts such as shaker screens and desander nozzles 1–2 times per month. The cost per maintenance is approximately ¥3,000–5,000, and each maintenance requires 4–6 hours of downtime. Based on a daily drilling revenue of ¥15,000, the loss per downtime event is about ¥3,000–3,750.Black Rhino energy-saving equipment, with an intelligent load adjustment system, automatically adapts power to mud concentration. Component wear is reduced by 40%–50%, monthly maintenance frequency drops to 0.5 times, saving over ¥20,000 annually in maintenance costs, while reducing downtime losses by approximately ¥18,000.Long-Term

Comprehensive Benefits: A mid-sized gas field project previously used two traditional 50 m³/h solids control units, with an annual total energy cost of ¥594,000.After switching to Black Rhino energy-saving equipment, annual electricity costs dropped to ¥396,000. With a basic waste-heat recovery system (commonly used in the industry), it could also meet 30% of on-site hot water demand, saving an additional ¥30,000 annually in energy costs.Based on a typical 8-year equipment lifecycle, cumulative savings exceed ¥178,000, enough to cover the initial purchase price difference (the cost gap between energy-saving and traditional units typically ranges from ¥100,000–150,000).

It is worth noting that energy-saving upgrades may also qualify for policy incentives.According to the National Guide for Industrial Energy-Saving Technology Applications, companies purchasing industrial equipment with Level 2 or higher energy efficiency can apply for subsidies of 5%–10% of the equipment investment (the exact percentage depends on local regulations). For example, a drilling company in North China purchased energy-saving solids control equipment and successfully received an 8% subsidy, reducing the initial investment. Black Rhino energy-saving products all meet national Level 2+ energy efficiency standards and can assist companies in preparing the necessary application materials.

If high energy consumption is dragging down your costs, Black Rhino Industrial offers a free energy-consumption diagnostic service: engineers measure equipment operating parameters on-site and calculate precise energy-saving potential based on actual working conditions. Among clients who have switched to energy-saving equipment, 80% have achieved a 25%–30% reduction in operating costs, ensuring that every kilowatt-hour is used efficiently.