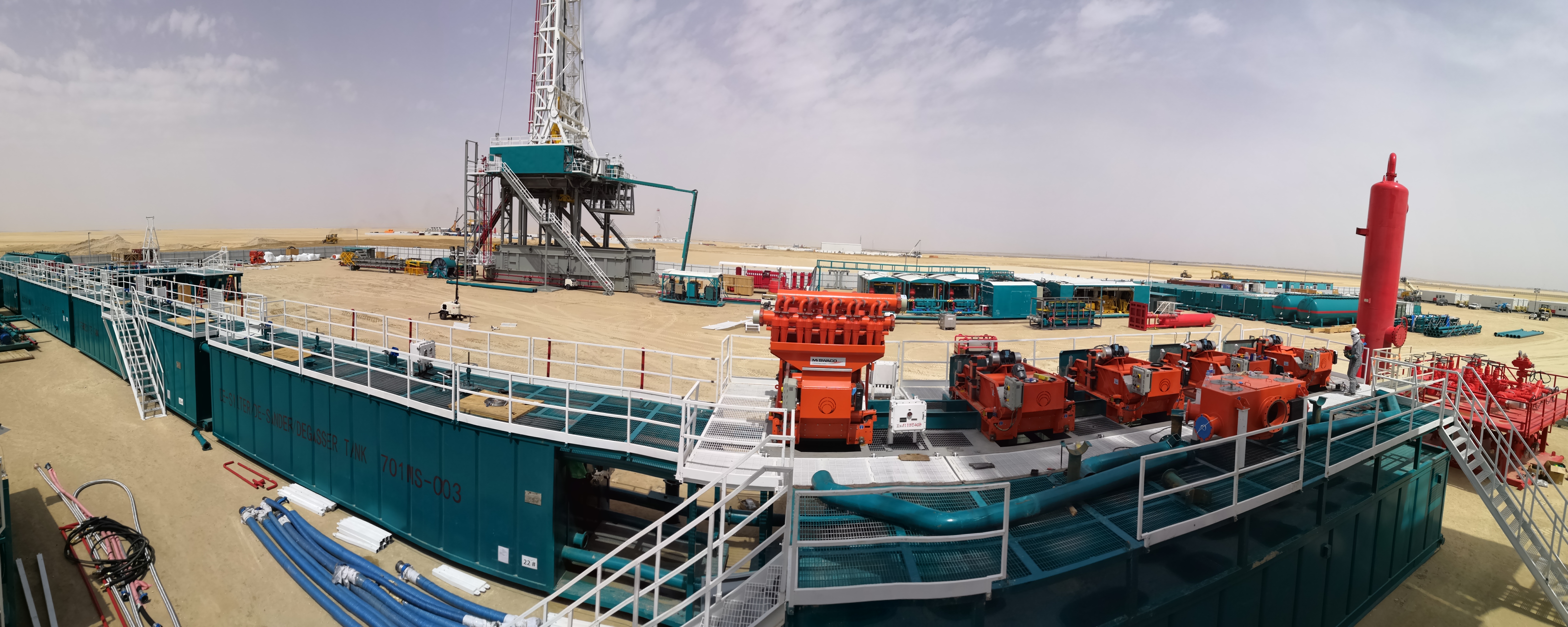

highefficiency black rhino shale shaker for mud solids removal

The highefficiency black rhino shale shaker represents a cutting-edge solution for mud solids removal in drilling operations. This advanced equipment utilizes precision-engineered vibration technology to effectively separate drill cuttings from valuable drilling fluids. The system features a robust design with multiple screen layers that process drilling mud through progressively finer mesh sizes, ensuring optimal separation efficiency. The shaker employs a unique dual-motion shaking pattern that combines linear and elliptical movements, maximizing the screening area while minimizing screen wear. Its high-capacity processing capabilities can handle flow rates up to 2000 GPM, making it suitable for both small and large-scale drilling operations. The black rhino shale shaker incorporates advanced composite materials in its construction, offering superior corrosion resistance and extended operational life. The system's intelligent control interface allows operators to adjust vibration parameters and monitor performance in real-time, ensuring consistent separation quality. The equipment's innovative screen tensioning system provides quick screen replacement and maintenance, reducing downtime and increasing operational efficiency. This shale shaker is specifically designed to meet the demanding requirements of modern drilling operations, offering reliable performance in diverse environmental conditions.