tailings dewatering system

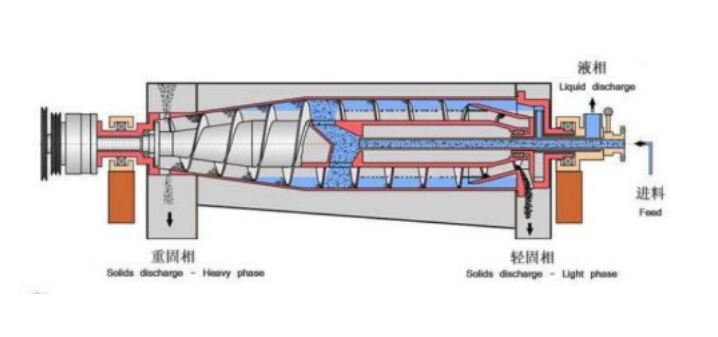

A tailings dewatering system is an advanced industrial solution designed to efficiently separate and recover water from mining waste materials. This comprehensive system integrates multiple stages of mechanical and chemical processes to achieve optimal moisture reduction in tailings material. The system typically consists of thickeners, filters, and dewatering equipment that work in harmony to process mining byproducts effectively. At its core, the system employs cutting-edge technology to minimize water consumption while maximizing the recovery of valuable resources. The process begins with the initial separation of solids from liquids, followed by advanced filtration techniques that further reduce moisture content. Modern tailings dewatering systems incorporate automated controls and monitoring systems to ensure consistent performance and reliability. These systems are adaptable to various mining operations, including precious metals, base metals, and mineral processing facilities. The technology has evolved to address environmental concerns and regulatory requirements, offering sustainable solutions for waste management in the mining industry. The system's versatility allows for customization based on specific site conditions, material characteristics, and production requirements, making it an essential component in modern mining operations.