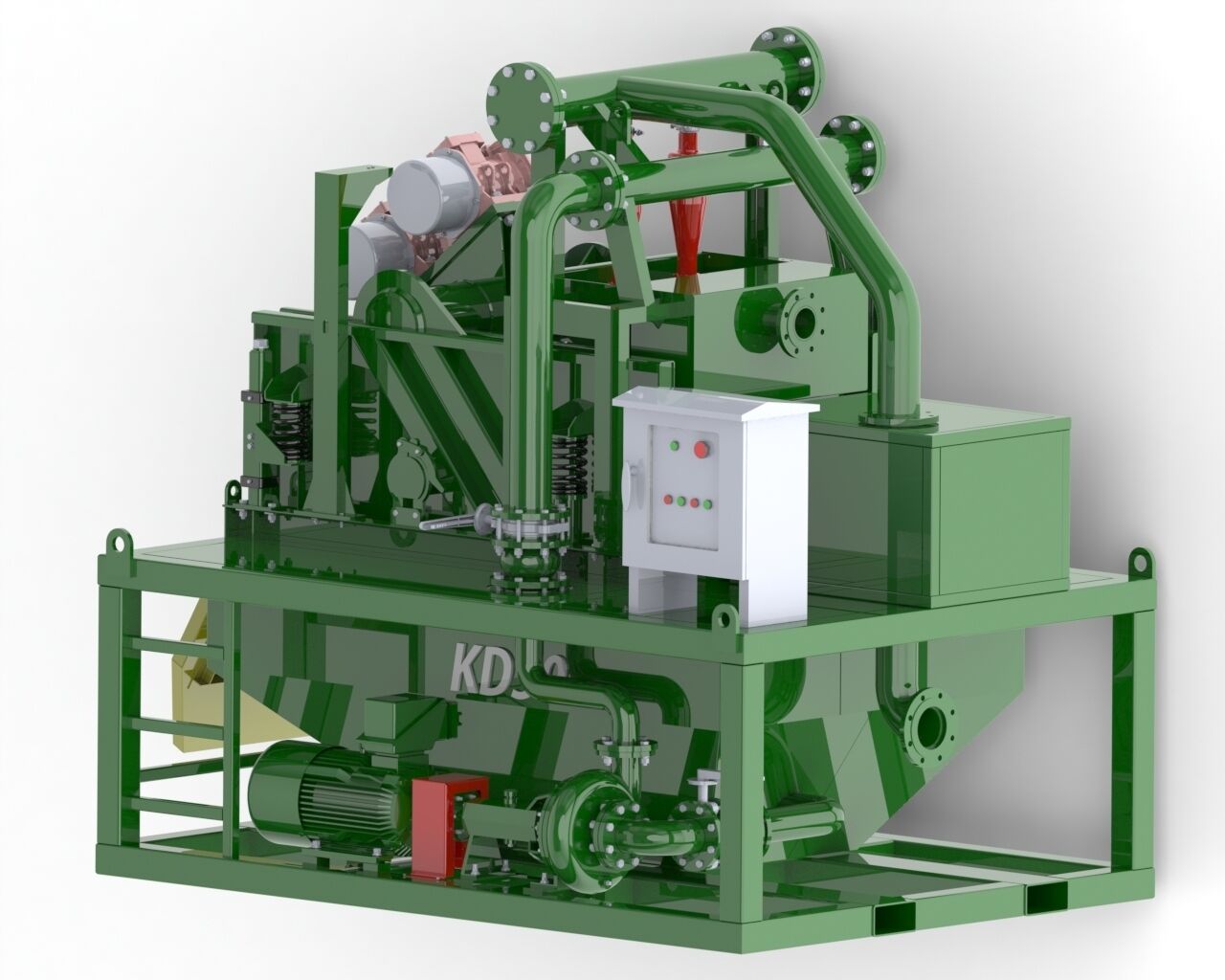

The Black Rhino KD-50 Shield Slurry Treatment System is a lightweight slurry purification equipment specifically designed for small slurry balance shield projects and medium-to-small scale underground engineering. With “efficient purification, flexible deployment, and economical practicality” as its core design philosophy, it is primarily integrated from four core components: vibrating screen, desanding cyclone, gravel pump, and conical tank. These components work in synergy to form a complete slurry purification closed loop, providing stable and reliable slurry treatment support for small construction scenarios.

|

|

I. Equipment Positioning & Core Composition

The Black Rhino KD-50 Shield Slurry Treatment System is a lightweight slurry purification equipment specifically designed for small slurry balance shield projects and medium-to-small scale underground engineering. With “efficient purification, flexible deployment, and economical practicality” as its core design philosophy, it is primarily integrated from four core components: vibrating screen, desanding cyclone, gravel pump, and conical tank. These components work in synergy to form a complete slurry purification closed loop, providing stable and reliable slurry treatment support for small construction scenarios.

II. Core Performance & Purification Capability

Precise Separation, Excellent Purification Effect: Equipped with a double-layer screen vibrating screen, the coarse screen efficiently intercepts large particle slag in the mud. Combined with the desanding cyclone and fine-mesh screen, it can accurately remove fine sand as small as 40 μm, ensuring the purified mud meets performance standards and satisfying the strict requirements for mud quality in shield construction.

Processing Efficiency Adapted for Small Projects: The equipment’s rated processing capacity is 50 m³/h, which can efficiently handle the slurry treatment needs of small shield projects, avoid resource waste caused by excess capacity, and ensure stable mud supply during construction without affecting progress.

Green & Environmentally Friendly, Pollution Reduction: Adopts closed-loop circulation purification for slurry, reducing slurry discharge. Simultaneously significantly reduces the moisture content of separated slag, which not only facilitates subsequent transportation and treatment of the slag, but also reduces construction pollution to the surrounding environment from the source, complying with green construction standards.

III. Equipment Advantages & Practical Features

Lightweight Design for Convenient Deployment: The total machine weight is only 2.1 t, with dimensions of 3 m × 1.8 m × 2.5 m. Its compact size and light weight result in low space requirements for the construction site. Whether in narrow underground construction areas or temporarily established construction sites, it can be easily installed and deployed, significantly reducing site planning difficulty.

Low Energy Consumption for Reduced Operating Costs: The total installed power is only 21.98 kW. While ensuring processing efficiency, it effectively reduces energy consumption during operation, significantly saving electricity costs over long-term use. Additionally, equipment accessories are made of corrosion-resistant and wear-resistant materials, resulting in low failure rates and long service life, reducing maintenance and replacement costs, further lowering overall operating costs.

Simple Operation & Maintenance, Lowering the Barrier: The treatment process is optimized to be simple and practical, requiring no complex operating skills. Ordinary construction personnel can become proficient after short-term training. Meanwhile, the equipment maintenance process is simplified, with no need to disassemble complex components for daily maintenance, saving maintenance time and labor costs and ensuring continuous stable operation.

Adaptable to Diverse Working Conditions: Although a small-scale equipment, its core components feature excellent corrosion and wear resistance, easily coping with the harsh working conditions common in shield construction such as dampness and high impurity levels. It also supports parameter adjustments such as vibrating screen excitation force and screen box inclination angle according to construction needs, flexibly adapting to mud treatment requirements under different geological conditions.

IV. Applicable Scenarios

The KD-50, with its advantages of lightweight, low energy consumption, and easy deployment, is mainly adapted to the following scenarios: