mudwater separator and sludge recovery equipment

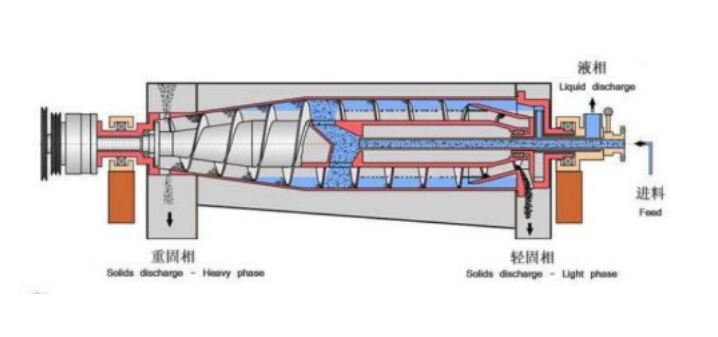

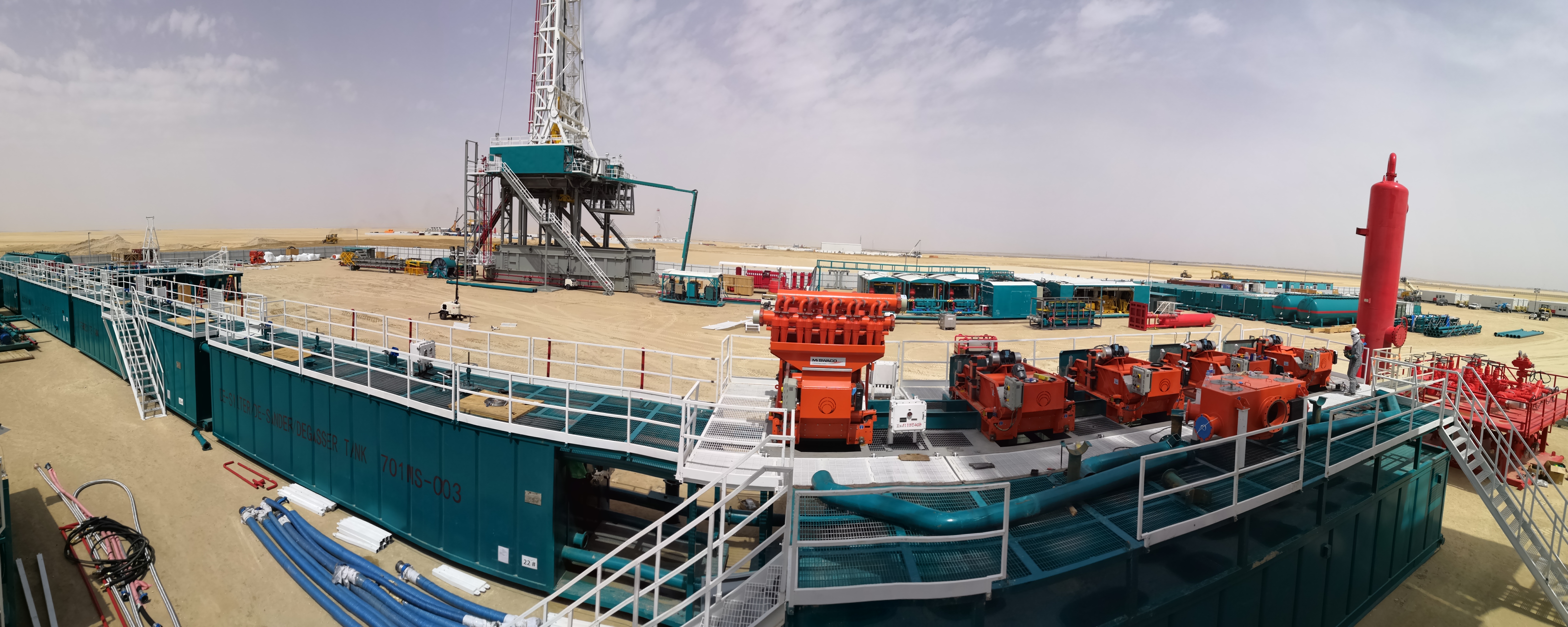

The mudwater separator and sludge recovery equipment represents a cutting-edge solution for efficient waste management and resource recovery in various industrial applications. This sophisticated system employs advanced separation technology to effectively divide mud, water, and other materials, enabling optimal resource utilization and environmental compliance. The equipment operates through a multi-stage process, beginning with the initial separation of solid particles from liquid compounds, followed by precise filtration and recovery mechanisms. The system's core technology utilizes centrifugal force combined with specialized screening methods to achieve superior separation results. Primary functions include the removal of suspended solids, recovery of valuable materials, and production of cleaner water output. The equipment is engineered to handle various input consistencies and can process significant volumes of material continuously. Applications span across construction, mining, oil and gas, and environmental remediation sectors. The system's adaptability allows for customization based on specific industry requirements, making it suitable for both small-scale operations and large industrial facilities. Advanced monitoring and control systems ensure optimal performance and efficiency throughout the separation process.