slurry treatment system for oilfield

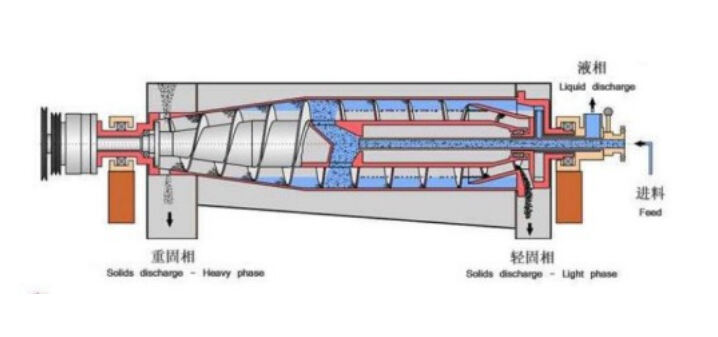

A slurry treatment system for oilfield operations is an advanced technological solution designed to effectively manage and process drilling waste materials. This comprehensive system integrates multiple treatment stages to handle various types of drilling fluids and cuttings generated during oil and gas exploration activities. The system employs sophisticated separation techniques, including mechanical separation, chemical treatment, and dewatering processes, to efficiently separate solids from liquids. The primary functions include the removal of suspended solids, reduction of fluid volume, and recovery of valuable drilling fluids for reuse. Advanced monitoring systems ensure optimal performance while maintaining environmental compliance. The technology incorporates automated control systems that adjust treatment parameters based on real-time data, ensuring consistent output quality. The system's modular design allows for easy transportation and setup at different drilling sites, making it highly versatile for various operational conditions. It can process different types of drilling wastes, including water-based, oil-based, and synthetic-based muds, with high efficiency and reliability. The treated water can be safely discharged or recycled, while the processed solids can be disposed of in an environmentally responsible manner or repurposed for other applications.